Industry pain points: Traditional construction safety problems

ForBeam moving machine, beam lifting machine, beam truck, bridge building machine and frame transport all-in-one machineAnd other full-process equipment, railway bridge construction faces multiple safety challenges:

- High security risk: The operation of large-scale equipment is complicated, and overturning and collision accidents are frequent, which seriously threatens the safety of personnel and equipment.

- Precision control is difficult: Key processes such as millimeter-level precise alignment, latch placement, and path control rely on experience, with large errors and low efficiency.

- There are many blind spots in condition monitoring: Hidden dangers such as fatigue of the metal structure of the equipment and wear of key components are difficult to detect, and there is a lack of real-time monitoring methods.

- Inefficient management: Manual inspection workload is large, multi-equipment coordination is difficult to unify, and data silos affect construction progress

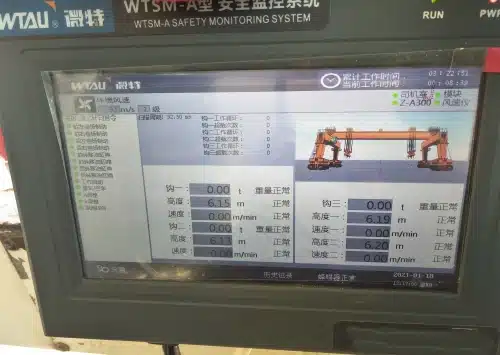

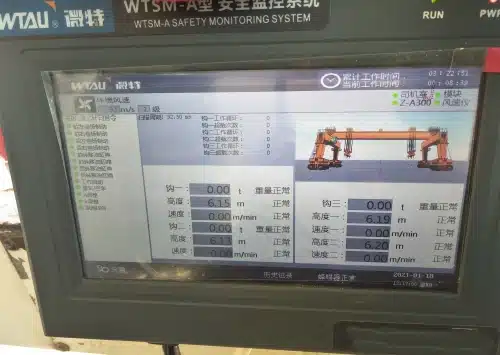

Safety monitoring system for beam moving machine/beam lifting machine

Beam moving machine/beam lifting machine safety monitoring system

Micro-special beam lifting machine safety monitoring system instrument

Safety monitoring and management system for beam moving machine/beam lifting machineIt is a set of intelligent safety solutions specially designed for large lifting equipment. It effectively prevents accidents by monitoring key data in real time and ensures the safe and efficient operation of equipment.

Core functions:

- Real-time monitoring and early warning: Monitor weight, height, wind speed and other data around the clock, sound and light alarms immediately when abnormal, and can automatically stop

- Data recording and analysis: Automatically record operation and violation data to provide a basis for safety management and fault diagnosis

- Remote management: Support computer/mobile phone remote viewing of real-time data, location and video to achieve convenient remote operation and maintenance

- Smart protection: Equipped with anti-collision and electronic area restriction functions to actively prevent equipment from colliding or entering dangerous areas

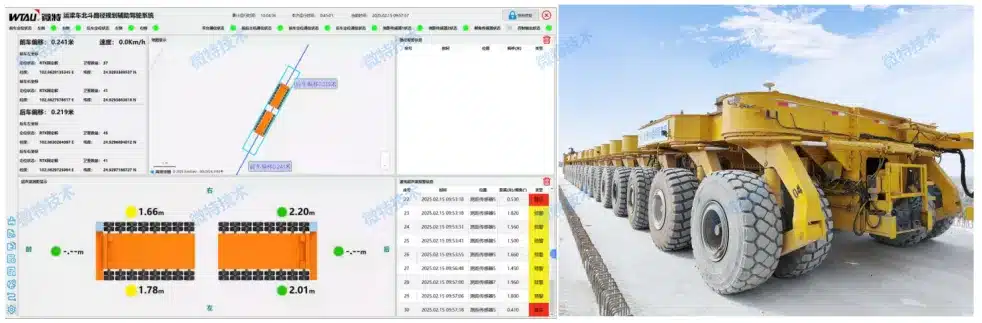

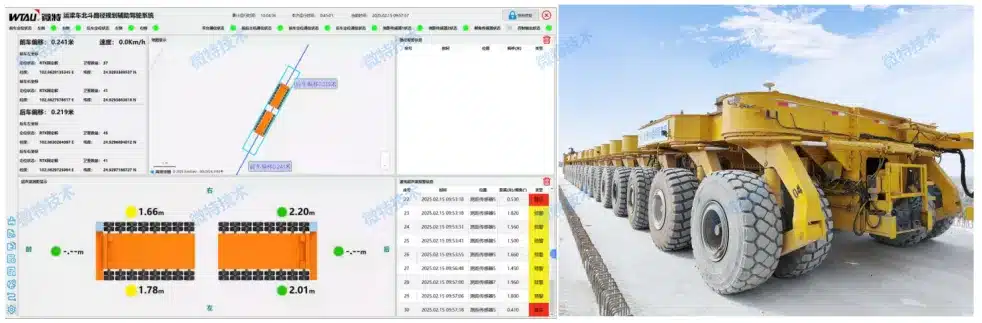

The correction management system of the micro-special beam truck uses Beidou's high-precision positioning to provide automatic path correction for the beam truck to ensure accurate, efficient and safe transportation of the 100-ton beam body.

Beam truck safety and path assistance system

Core functions:

- Automatic correction: Real-time detection and automatic adjustment of the driving direction to ensure that it travels along a predetermined path

- Precise positioning: Beidou millimeter-level positioning, beam alignment error is controlled within 3 mm

- Comprehensive protection: Integrated 360° anti-collision and video surveillance to ensure safety in all directions

- Intelligent adaptation: Adapt to a variety of complex environments such as mountains and tunnels, and maintain stable work

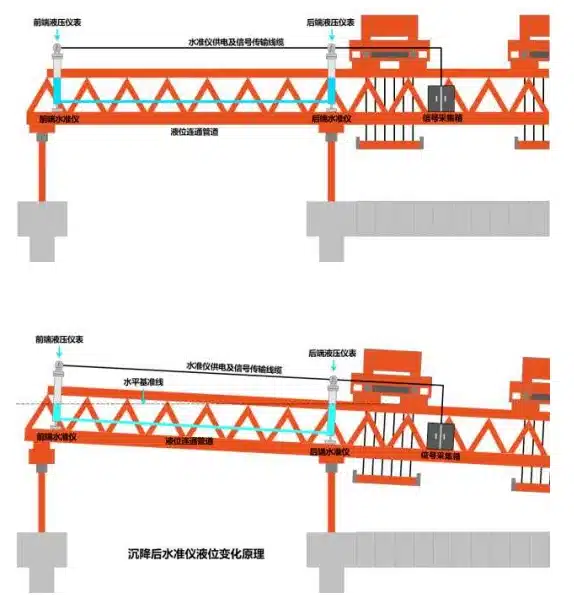

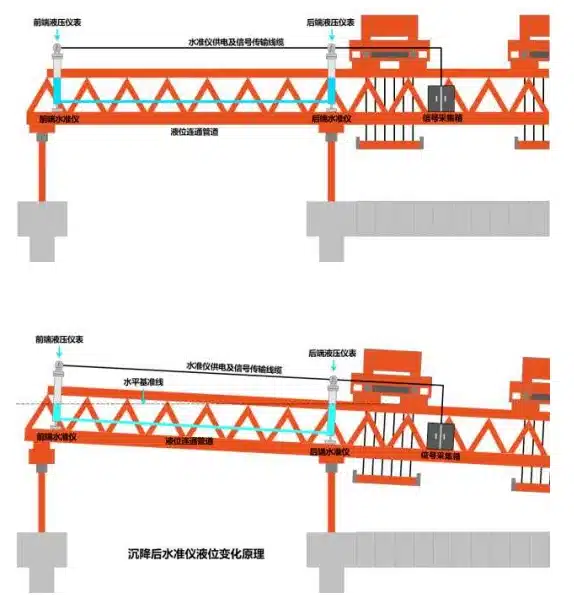

An intelligent monitoring scheme designed for the bridge-building machine to be prone to instability accidents in key processes such as vias and beams. The system effectively prevents the risk of overturning and guarantees construction safety by monitoring the level of the main beam, the parallelism of the outrigger track and the attitude of the beam body in real time.

Core functions:

- Main beam level monitoring: Real-time monitoring of the height difference between the front and rear of the bridge-building machine to ensure that the equipment maintains a safe attitude of "front height and rear low", and automatically alarms when abnormal.

- Orbital parallelism monitoring: Monitor the parallelism of the two traversing tracks, display the error in real time and support precise adjustment to control the parallelism error at the centimeter level

- Beam attitude monitoring: Sensors are used to monitor the tilt angle and distance from the ground of the beam body in the construction of high and low hoisting in real time, and assist the operator to control the stability of the beam body.

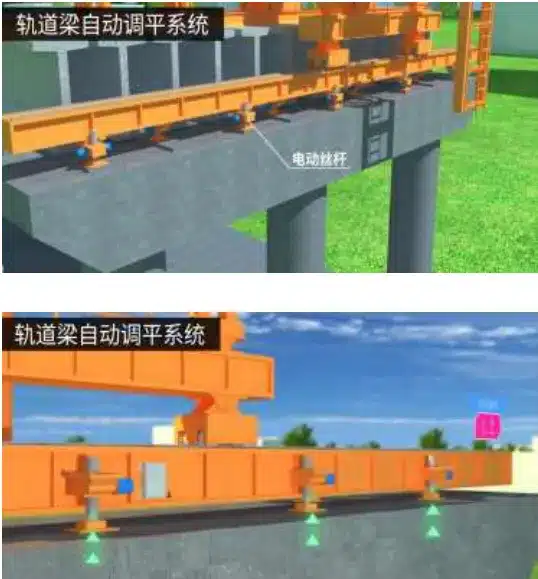

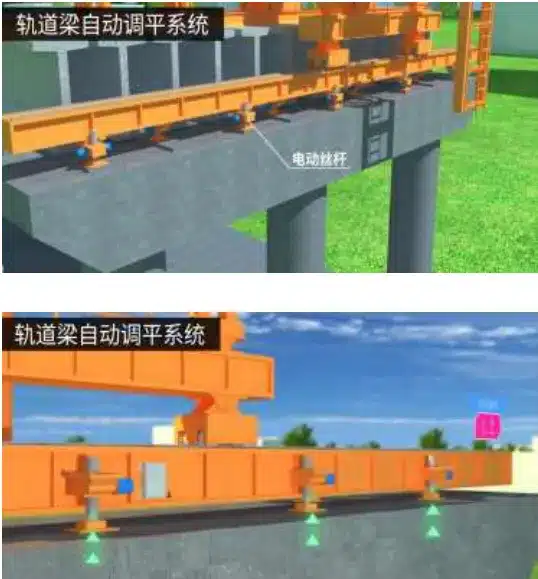

Through electrical automation control technology, it replaces the traditional manual leveling operation, and realizes the automatic and precise leveling of the leg position of the bridge-building machine after the vias, effectively improving construction safety and efficiency.

Core functions:

- Automatic electrical leveling: The electric support screw and electrical control system are used to automatically complete the operation of the fulcrum position and level adjustment of the track beam, replacing high-intensity manual operations.

- Multi-fulcrum collaborative support: After leveling, the system automatically controls each fulcrum point to complete the support action, and monitors the force state through the load sensor to ensure reliable and safe support.

- Real-time data monitoring and early warning: Real-time display of leveling data and support status of each node, automatic early warning of abnormal conditions, to solve the security risks of manual leveling without data verification

The AI detection system of the outrigger pin of the bridge-building machine uses machine vision intelligence to identify the status of the pin in place, replacing manual inspection, and effectively preventing the risk of instability of the outrigger.

Core functions:

- Multi-point visual monitoring: A single host supports multiple cameras, with full coverage to monitor the status of each leg pin

- AI intelligent recognition: Adaptively identify pins of different specifications, and accurately judge the status of the pin in place

- Real-time alarm synchronization: Instant sound and light alarm in abnormal state, data synchronization on remote platform

Realize a paperless and standardized digital management platform for equipment inspection, effectively improve inspection efficiency and equipment reliability.

Core functions:

- Paperless inspection: Integrate the whole process of task distribution, on-site execution, and result reply to ensure that the inspection data is true and traceable

- Closed loop management: Realize the full online management of task distribution, execution, verification, and evaluation

- Smart report: Automatically generate multi-dimensional statistical reports to provide data support for equipment maintenance

The information system of suspension irrigation bridge-building machine is a special safety monitoring platform developed for modern large-section cantilever pouring construction. It effectively guarantees the safety and quality of bridge-building machine construction by monitoring key parameters such as equipment balance and structural stress in real time.

Core functions:

- Balanced construction monitoring: Force sensor and Beidou positioning technology are used to monitor trace balance and concrete pouring weight balance in real time to prevent the risk of overturning

- Multi-parameter safety monitoring: Integrated all-round monitoring of equipment tilt, walking distance, structural stress, environmental data, etc., to fully control the operating status of the equipment

- Intelligent video linkage: Covering video surveillance of the construction site, linkage with the data platform to alarm, and realize visual safety management

- Remote data platform: Provide local and remote real-time data kanban boards, support construction guidance, alarm push and remote observation, and meet the management needs of multiple parties