Product introduction: content hide 1. Introduction and purpose 2. Main application scenarios ……

Model: WTSM-A-06

The Gantry Crane Safety Monitoring and Management System is an enhanced safety monitoring device designed and manufactured for cranes in the ship repair and construction industry.Optimized for extreme working conditions of shipbuilding and repair cranes,such as long operating hours, frequent vibrations, high temperatures,and heavy dust,the system provides comprehensive and reliable safety monitoring and management functions. Its core functions include operating status recording, in-depth data analysis, fault diagnosis, and service life early warning for key components.It meets the requirements of the national standard GB/T 28264-2017 Crane Safety Monitoring and Management System.要求。

Dedicated to loading and unloading industries such as ports, docks, and shipyards

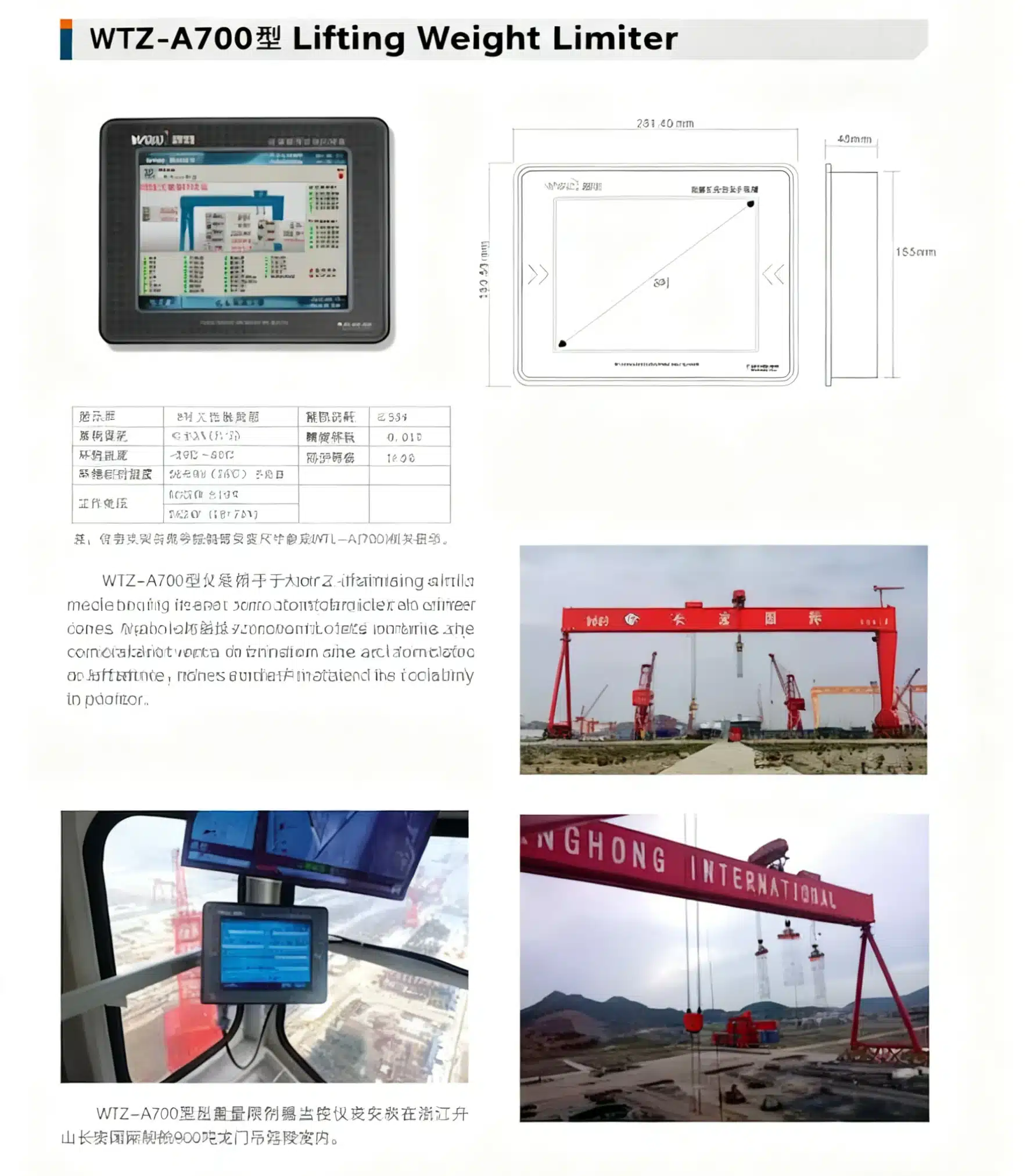

Applicable to large lifting equipment including shipyard gantry cranes and gantry cranes.

Featuresenhanced protection design for high-temperature,heavy-dust, and continuous vibration environments to ensure stable operation of the system under harsh working conditions.

List of core acquisition modules

① Lifting Weight Sensor (needs to be adapted to the signal output of the overload limiter)

② Absolute Encoder (for monitoring lifting/lowering height)

③ Absolute Encoder (for monitoring travel distance of the main/trolley)

④ Wind Speed Sensor (automatically triggers shutdown protection)

⑤ PLC/Operation Command Acquisition Module (linkage console or operation buttons)

⑥ Lifting Brake Status Sensor

⑦ Operation Interlock Status Acquisition Module

⑧ Wind-Resistant and Anti-Skid Device Sensors (rail clamps, anchoring status, etc.)

> Note:Equipment without configured signal output devices needs to be upgraded or equipped with corresponding sensors.

Intelligent monitoring and analysis

– Hook Slippage Monitoring and Early Warning:Real-time diagnosis of abnormalities in the lifting brake.

– Fault logic diagnosis:Automatic analysis of the root cause of control faults.

– Service Life Early Warning:Prediction of the remaining service life of key components (e.g., brakes).

High Reliability Design

– Multi-environmental adaptability:High-temperature resistance, dust prevention, and anti-vibration structure.

– In-Depth Real-Time Data Processing:Goes beyond basic recording functions to provide decision support.

Compliance Assurance

Compliance guarantee

- Fully complies with the monitoring requirements of the national standardGB/T 28264-2017GB/T 28264-2017.

– GB 12602-1990Safety Technical Specification for Overload Protection Devices of Lifting Machinery

– GB 6067.1Safety Regulations for Lifting Machinery

– GB/T 28264-2017GB/T 28264-2017 Lifting Machinery - Safety Monitoring and Management System

– GB/T 20776Classification of Lifting Machinery

Monitoring item Implementation method Functional value

Lifting Weight Signal acquisition from overload limiter Instant overload protection; equipment without signal output needs replacement

Lifting/Lowering Height Absolute encoder Real-time grasp of hook position; unmonitored equipment needs additional installation

Main/Trolley Travel Distance Absolute encoder Accurate positioning of travel distance

Wind Speed Wind speed sensor Automatic shutdown when wind speed exceeds the standard

Operation Command Signal acquisition from PLC/linkage console Real-time feedback of operation status

Brake Status Dedicated sensor Quick fault location to ensure operation safety

抗风防滑装置 夹轨器/锚定状态传感器 防风措施状态可视化

The WTSM-A-06 system not only meets the national standard requirements for recording and displaying crane operation data but also realizes active safety protection through in-depthdata analysis(such as hook slippage early warning, fault diagnosis, and service life prediction). It significantly improves the safety management level and accident prevention capability of gantry cranes in ship repair and construction scenarios.

Next Article:Safety monitoring and management system for bridge building machine »