Product introduction: Content Hide I. Industry Pain Points and Policy Background Ii. Core Objectives of the Solution ...

Railway laying and erection equipment has long been confronted with challengesHarsh working conditions in the wild、Difficulties in management and maintenanceIn recent years, bridge erection machine overturning accidents have occurred frequently due to such challenges, resulting in machine destruction, casualties, project delays and huge losses. With the acceleration of high-speed railway construction, the intensity of equipment usage has increased sharply, and safety risks have continued to escalate.

Policy mandatory requirements:

According to Document No. 23 of The State Council [2010], Document No. 140 of The General Office of the State Council [2010] and Document No. 5 of the General Office of Quality Inspection and Quarantine [2013], the state mandatoringly implements the "Safety Monitoring and Management System for Lifting Machinery" (GB/T 28264-2012), requiring large lifting machinery to be equipped with a safety monitoring system to achieve accident prevention and improvement of intrinsic safety.

This plan is specifically forSection assembly bridge erection machineCustomized, in line with the national standard GB/T 28264-2012, achieving:

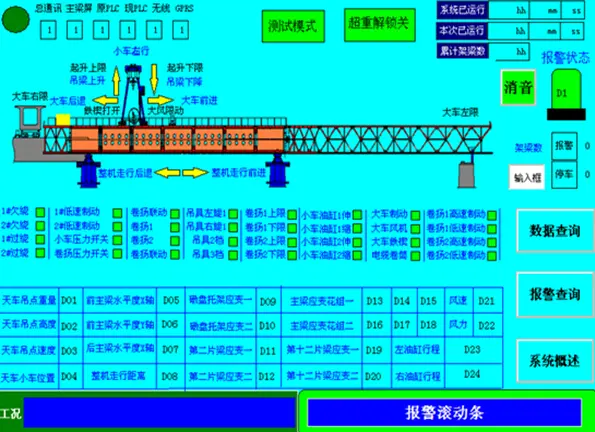

✅ Real-time multi-parameter monitoring|✅ Fault traceability and self-diagnosis|✅ Sound and light alarm linkage

✅ Visualization of job status|✅ 72-hour video loop storage|✅ Open Data Protocol

Wireless transmission system(Solve the problem of crane movement)

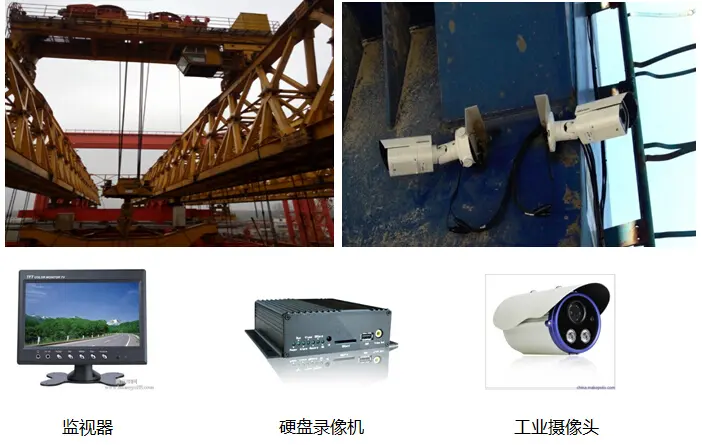

– Crane workstationIntegrated sensor cluster (weight/tilt/displacement) and three high-definition cameras (covering lifting points, front/rear working surfaces)

– Main beam workstationReceive wireless signals (2.4GHz/5.8GHz dual-frequency anti-interference), embedded processing core

– Remote control operation compatibilityCompatible with mainstream industrial remote control systems

2. Triple security guarantee module

| Module | Function description |

| Data monitoring Real-time collection of 32 parameters such as load capacity, balance degree, and track offset, with automatic locking when the limit is exceeded

| Video surveillance | 2-megapixel anti-shake camera, supporting night vision; H.265 encoding storage ≥72 hours of loop video recording |

| Remote cloud platformOptional 4G/GPRS module, data is directly transmitted to the cloud server, supporting real-time monitoring on PC/ mobile devices (distance ≤10KM)

3. Industrial hardware deployment

- Main beam terminal: IP65 rainproof box body, embedded 10-inch industrial touch screen (wide temperature operation range -30℃ to 70℃)

- Data storage: Local 30-day continuous working records, supporting USB/ Ethernet export

- Alarm device: 120dB buzzer + red strobe light, full coverage of dangerous areas

| Function | Customer revenue |

| Overturning warning | Multi-sensor fusion algorithm predicts overturning risk 15 seconds in advance |

| Derailment self-diagnosis An immediate alarm will be triggered when the track offset exceeds 3mm, and historical data can be used to trace the cause of the accident

| The hoisting process is visible | Key area video picture-in-picture display eliminates operation blind spots |

| Remote supervision The project department/headquarters can view the equipment status in real time to reduce on-site management costs

1. Rapid transformationModular design, seamless installation of in-service equipment

2. Wiring constructionThe crane and the main beam communicate wirelessly to prevent cable failures in the wild

3.Customized interfaceThe interactive GIS map displays the device's posture, with alarm information pop-up Windows taking priority

> Authoritative certificationThis system has been certified by the National Quality Supervision and Inspection Center for Lifting and Transport Machinery (Report Number: QEJC-2023-G328), and meets the full-scenario construction requirements for high-speed railways and ordinary railways.

Previous: Door and landline security monitoring and management system

Next Article:Wtau hydroelectric power station intelligent door machine new technology application is too good! »