Industry pain points: Traditional monitoring methods face challenges

Traditional hydraulic metal structure equipment (such as gates, open and close machines, etc.) relies on manual inspection and regular maintenance, and there are many problems.:

- Inefficient: Manual testing has a large workload, relies on empirical judgment, and is prone to missed inspections and misjudgments.

- High security risk: The high-altitude and underwater operating environment is dangerous, and the inspectors are vulnerable

- Cannot be monitored in real time: It is difficult to capture early signs of sudden failures

- Short equipment life: Lack of data support, unable to achieve predictive maintenance

The safety monitoring system of the micro-special dam top gate machine is mainly used for the safety monitoring and management of gate maintenance of water conservancy projects. It ensures the safety and accuracy of gate operation through real-time collection of key parameters, visual monitoring of underwater operations, encrypted storage of data, automatic locking of abnormal instructions and compatibility with a variety of control systems.

Main functions:

- Real-time dynamic data collection: Collect key parameters such as the alignment state of the grab beam, the depth of the pin, and the hydraulic pressure to ensure that the gate lifting and discharging are accurate and controllable.

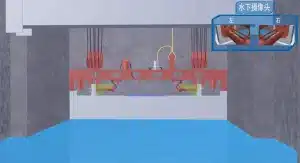

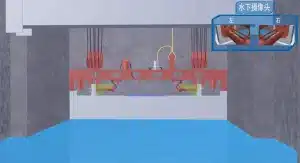

- Underwater operation monitoring: The operation screen is transmitted in real time through the underwater high-definition camera to realize the visual monitoring of the pin alignment process. When the pin is in place, the gate is hoisted to avoid the risk of the gate falling.

- Encrypted data storage: Support historical data traceability and fault analysis to solve the problem of lack of basis for fault traceability

- Compatibility design:PLC communication or switch command acquisition, adapt to old equipment, reduce the difficulty of door machine transformation

Visualization of hydraulic grab beam

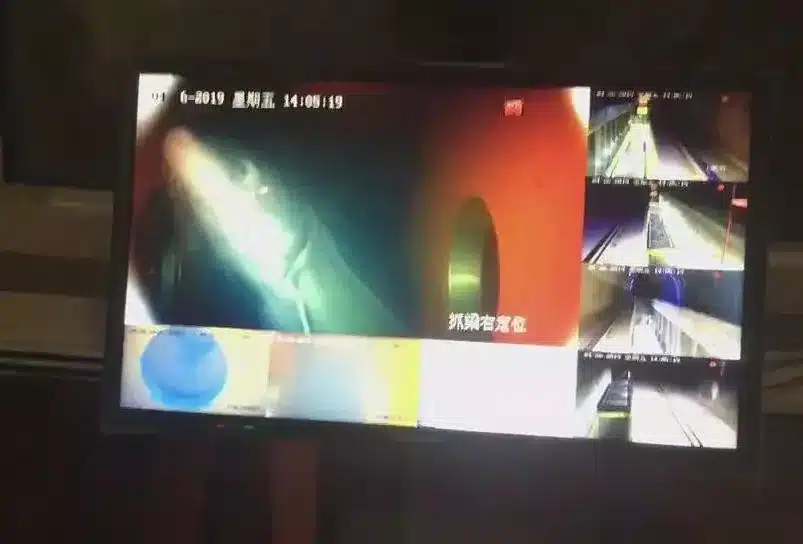

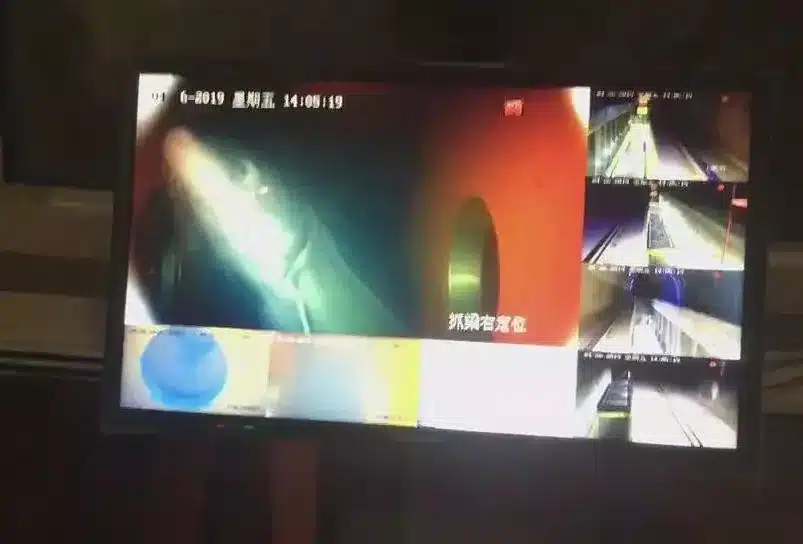

Monitoring screen of the cab of Xiangjiaba tailwater trolley

The hydraulic grab beam visualization integrated monitoring system adopts real-time dynamic data and underwater visualization video methods (after monitoring the normal alignment of the grab beam and the gate, then perform the connection between the pin and the gate, and confirm the pin of the grab beam in place under the data visualization and carry out the lifting gate) to ensure that during the maintenance of the unit or decontamination, the hydraulic grab beam visualization integrated monitoring system adopts real-time dynamic data and underwater visualization video methods (after monitoring the normal alignment of the grab beam and the gate,The hydraulic grab beam is safe and reliable to lift and release the gate.

Core functions:

- Deep water visual monitoring: Using WTDC underwater high-definition digital camera, it can clearly show the process of penetration and out-of-stock of the grab beam in deep water, observe the underwater alignment and gate status, and avoid equipment blocking or operating errors caused by blind spots in the line of sight.

- Stable signal transmission: Through professional deep-water cables, data can be stably transmitted underwater at a depth of 200 meters, video and sensor data transmission can be completed, and multiple cameras can share signal lines, which greatly simplifies installation and maintenance.

- Muddy water penetration: Built-in imaging technology and intelligent fill light, which can see objects clearly in muddy waters

- High pressure waterproof: Passed the >3MPa hydrostatic pressure test at the factory to ensure the tightness of deep-water operations

The electrical equipment transformation of the water gate machine mainly includes control cabinets, electrical control components, cables, automation components (encoders, load sensors, stroke limiters, etc.), linkage operation consoles, etc.

Core functions:

- Control cabinet: Stainless steel or carbon steel spray material can be used according to customer requirements. The recommended material thickness is 1.5mm stainless steel and 2mm carbon steel. The size of the control cabinet can be customized according to on-site conditions

- Electrical control components: It mainly includes PLC, circuit breakers, contactors, relays, etc., mainly using imported brands such as Siemens and Schneider, and can also be replaced with well-known domestic brands according to customer requirements.

- cable: Including the replacement of power cables and communication cables, the erection of cable trays and the laying of cables

- Linkage console: Provide a reliable operating platform for crane operators. Each console is equipped with a seat that can be adjusted up and down, front and rear

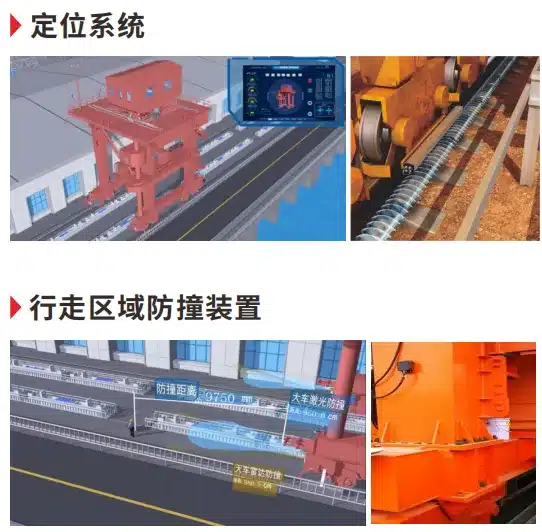

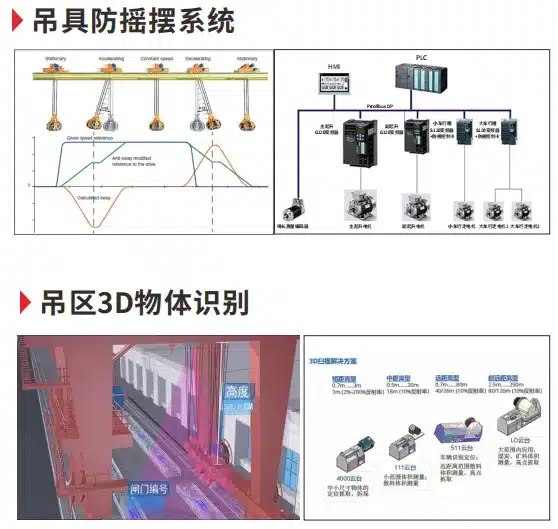

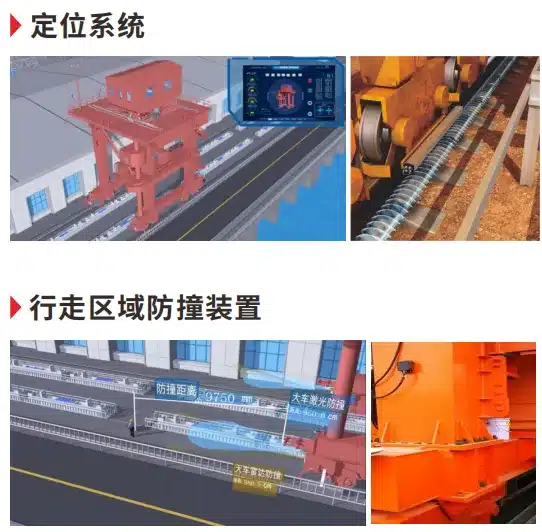

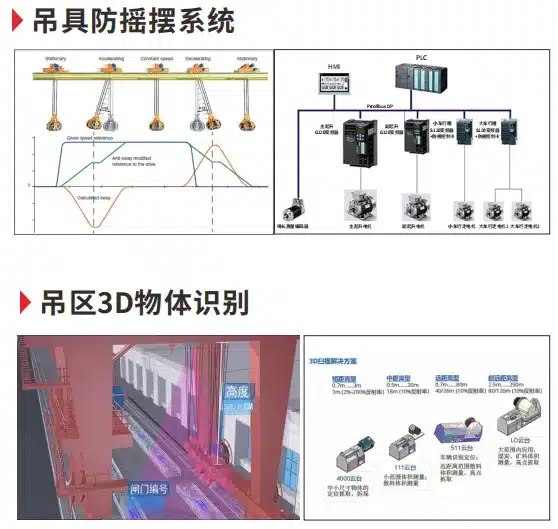

The one-key hoisting system of the intelligent door machine realizes the ”one-key” automated operation of hoisting operations through precise positioning, automatic control and real-time monitoring technology. The system can automatically calculate the center of gravity, intelligent locking and precise alignment, greatly improve operation safety and efficiency, and support remote control, effectively reduce the risk and intensity of manual operations, suitable for ports, hydropower stations and other heavy-duty scenarios.

Core functions:

- Automatic locking beam device for gate

- Automatic positioning device for door machine walking

- Spreader anti-swing device

- Anti-collision device for obstacle recognition in hanging area

- Intelligent brake detection device

- Intelligent power supply reel control device

- Wireless control and remote monitoring system

- Online monitoring of the main structure, transmission components, and safety performance of the door machine

Application scenario: Hydraulic structure is widely used

The online monitoring system of arc gate is suitable for various hydraulic metal structure scenarios:

- Hydropower station: Monitoring of spillway gates

- reservoir: Monitoring of water intake gate

- Pumping station: Temperance gate monitoring

- Sluice engineering: Tide gate monitoring

- Water transmission project: Monitoring of sub-sluice gates

- Hydroelectric power: Unit inlet gate