Product introduction: content hide 1. Introduction and purpose 2. Main application scenarios ……

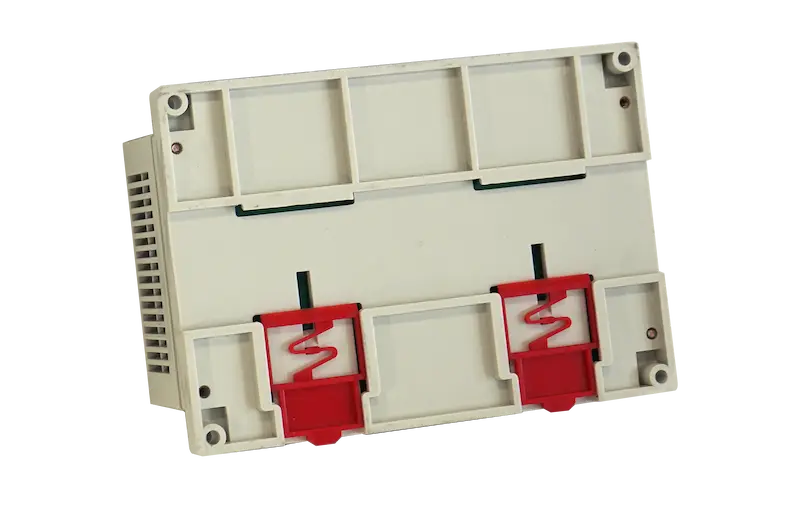

Model:WTYJ-PD

Product positioningIntelligent distribution box monitoring instrument, supporting real-time electrical data collection, energy consumption measurement and safety early warning. Through the new generation of Internet of Things communication technology, the cloud integration of data such as voltage, current, temperature, power consumption and fault alarm on the user side is achieved. Combined with big data analysis and remote control, it empowers the intelligent management of power consumption sites.

Core functions:

-Real-time monitoring of voltage, current, power and cable temperature

-Energy consumption measurement and detailed electricity consumption analysis

- Fault early warning protection (overvoltage, undervoltage, overload, etc.)

-PC remote/time-limited electrical control

- Data integration with third-party systems (supporting MODBUS protocol)

Application site:

-Family, dormitory, rental housing

-Municipal engineering (Street lamp monitoring)

-Farms, smart agriculture

-Intelligent buildings, smart schools, hotels

-Financial system, mobile communication base stations

-Smart energy consumption management, power big data platform

Basic configuration:

High-performance microcontroller (MCU)

② Electrical parameter acquisition module (voltage/current/temperature sensor)

③ Internet of Things communication Module (RS485/4G)

④ Smart Energy Service Cloud Platform

⑤ Mobile APP control terminal

Extended compatibility:

- Support access to third-party monitoring systems (MODBUS protocol)

- Customizable configuration of protection parameters (current and power limit values)

Intelligent Internet of Things architecture:

-7-channel high-precision signal acquisition (22-bit waveform, 6.4kHz update frequency)

-DMA mode data direct transmission reduces the load on the MCU

Industrial-grade reliability:

Wide dynamic range measurement (10,000:1 active energy error <0.1%)

-Military-grade circuit protection (rated insulation voltage 500V, impulse withstand voltage 6kV)

Multi-functional integration:

- Segmented angular difference correction (±2.8°), small-signal accelerated meter calibration

Three-phase three-wire/four-wire adaptive, neutral wire current monitoring

Cloud interaction capability:

- Real-time data upload to the cloud (voltage, current, temperature, active/reactive power)

- Remote parameter modification, timed self-check and fault log push

WTYJ-PD Smart Electricity Consumption Management Platform

Panoramic monitoring:

- Dynamic cockpit: Real-time display of multi-dimensional data such as voltage, current, power, power factor, and temperature

- Abnormal red alert: Thresholds such as overvoltage, undervoltage, overload, and leakage trigger early warnings

Intelligent defense:

- Three-level protection mechanism: Cloud warning →APP push → Automatic power-off

Monthly self-inspection of leakage and proactive reporting of potential hazards

Data-driven decision-making:

- In-depth energy consumption analysis: Generate electricity consumption reports and load trend charts (supports PDF/Excel export)

- Historical data traceability: ≥180 days of operation record storage

Remote collaboration:

- PC/APP remote control: Timed on/off, power limit, and battery level limit

- Fault handling linkage: Push maintenance plans and support one-click emergency stop

The WTYJ-PD type monitoring instrument meets IEC 62053-21/22/23:2020 International standards, through the "cloud-pipe-end" integrated architecture, achieve full life cycle optimization from electrical data collection, safety protection to intelligent management. Its high-precision measurement (error <0.1%), industrial-grade protection (withstand voltage 6kV), and open compatibility (MODBUS protocol) provide low-carbon and safe intelligent solutions for various power consumption scenarios.

Previous: Weite Technology facilitated the successful delivery of the 22,000-ton-meter "King of Tower Cranes"

Next Article:AI anti-intrusion system: intelligent security protection solution for lifting equipment hoisting area »