Product introduction: content hide 1. Does your warehouse also face these three "pain points”? 2. Micro-special solution: hard……

In modern warehouse management, we not only pursue the ultimate improvement of logistics efficiency, but also cannot ignore the safety of front-line operators. However, the warehouses of many companies are still facing the embarrassing situation of “not being able to see where the assets are, relying on manual command, and relying on data statistics.”

Launched by micro technologyIntelligent warehousing information system, It is precisely to solve these problems. By installing a “positioning brain” on the driving hook, we can achieve precise control of people, goods, and the field, and truly achieve a win-win situation of safety and efficiency. .

In traditional warehousing operations, the pain points are often concentrated in “invisible” and "unmanageable”.:

1. The location of the hook is “hide and seek”, which is difficult to find in the background Where the driving hook was, it used to be stared at by the ground personnel with the naked eye. Once background scheduling or traceability is required, it is difficult to quickly and accurately know which coordinate the hook is hanging on at the moment, which is time-consuming and laborious. .

2. The allocation of warehouse locations is “based on feeling”, and the space is easy to waste. The field of vision of the ground command personnel is limited, and it is difficult to see the whole picture clearly. When ordering the placement of goods, it is often difficult to allocate reasonable warehouse space. If you can bind the real-time location of the hook to the location information, you can clearly know whether each pit is empty or full, and completely say goodbye to the "fish that missed the net”. .

3. Entry and exit control is “manual", and efficiency cannot be improved. Do you still have to manually fill in the form to register for the entry and exit of goods? This traditional method not only relies too much on manpower, but is also prone to errors, resulting in automated management in a formality that cannot meet the efficient rhythm of modern logistics. .

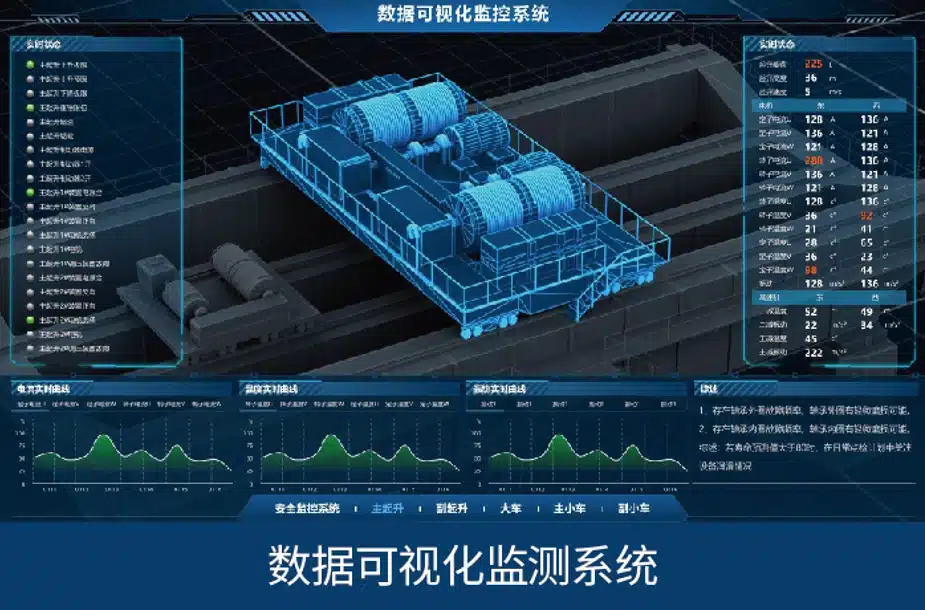

In view of the above problems, WeiteIntelligent warehousing information systemA set of “combination punches” was played, which allowed the data to speak through driving positioning, hook tracking, and linkage throughout the park.

We are not “blindly dry” in the warehouse. By arranging in the library area UWB positioning base station、RFID reading systemandAbsolute encoder, The system can accurately lock every position of the vehicle in the three-dimensional space like GPS .

Real-time visibility: With the micro-special weighing system, every lifting and every action is recorded in real time and displayed accurately. .

Data black box: All job data is safely stored locally in the form of a “black box” and uploaded to the background management system synchronously. .

Intelligent analysis: The system is not only about recording, but also helping you settle accounts-how is the crane's work efficiency? How many times have you moved throughout the day? Where did the goods go? What is the tonnage in and out of the warehouse? At a glance .

For three-dimensional library scenes such as steel coils, micro-specialIntelligent warehousing information systemIntelligent transformation of the original driving or gantry crane through edge computing technology .

Can not only locate, but also "think”: The system analyzes the loading and unloading weight in real time, tracks the movement trajectory, and analyzes the hoisting behavior. .

Graphical management: It realizes the three-dimensional positioning of the goods, intelligent finding of the goods, accurate delivery and graphical inventory. This not only greatly reduces the dependence on skilled workers, but also makes a qualitative leap in work efficiency. .

Our vision goes beyond the interior of the warehouse. Relying on Weite WTAU IOT central station,Intelligent warehousing information systemCan be connected to smart barriers, floor scales, video surveillance, driving, electronic scales and even environmental sensing equipment .

Full process automation: From the appointment of vehicles to enter the factory, intelligent queuing, to automatic release, automatic weighing, and automatic replacement of orders, the entire process flows smoothly, helping the park to achieve truly intelligent closed-loop management. .

Conclusion

Say goodbye to extensive management and embrace the digital future. Micro specialIntelligent warehousing information system, Through accurate positioning technology and strong data analysis capabilities, to help you see every corner of the warehouse clearly and calculate every work account.

Previous: Reservoir Digital Twin Platform: Smart Reservoir Solution

Next Article:Micro-special gate remote control system solution: Help the intelligent transformation of water conservancy and hydropower projects »