Product introduction: content hide 1. Industry pain points 2. Product introduction 3. ……

As the lifeline of energy transmission, oil and gas pipelines carry media that are typically flammable, explosive, volatile, and highly toxic. With the continuous expansion of pipeline networks and extended service life, the industry faces increasingly severe safety challenges.

Environmental risks and corrosion challenges: Long-distance pipelines have been in a complex soil or underwater environment for a long time, and formation movement, geological disasters, and natural erosion can easily cause deformation or corrosion and perforation of the pipe structure.

Frequent Third-Party Damage: Third-party intrusions such as human construction and illegal drilling/theft are major causes of pipeline leaks. Traditional monitoring methods struggle to provide early warning.

Limited Monitoring Range and Precision: Traditional point sensors have low density, failing to cover tens of kilometers of pipelines. They also exhibit poor reliability in harsh environments, often detecting incidents only after they occur, with no early warning capability.

High Operation and Maintenance Costs: Manual patrols are inefficient and fail to detect hidden early-stage hazards. Post-accident repairs and environmental remediation result in significant economic losses and negative social impacts.

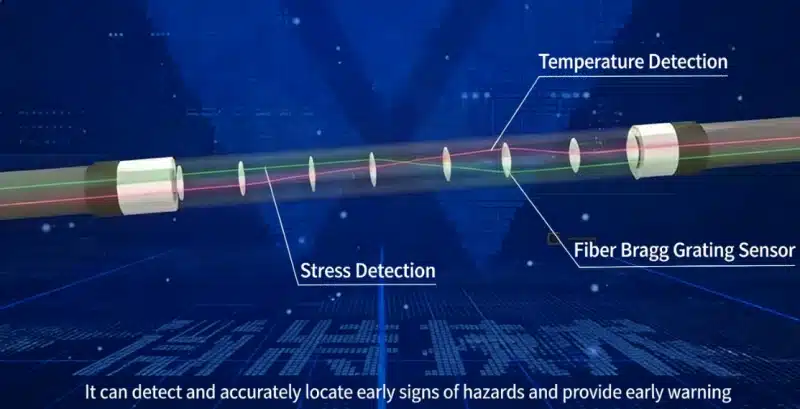

The Ultra-Weak Fiber Bragg Grating (WFBG) Pipeline Integrity Monitoring System is a high-precision online monitoring product developed for oil and gas pipeline safety. The system embeds optical fibers as sensing nerves along the pipeline, integrating Distributed Acoustic Sensing (DAS) and Ultra-Weak Fiber Bragg Grating (WFBG) technologies. It enables all-weather, full-range perception of perimeter vibration, stress changes, and temperature anomalies along the pipeline, achieving high-precision positioning and multi-parameter comprehensive monitoring in harsh environments. This provides digital decision support for predictive pipeline maintenance.

This solution deploys specialized optical fiber sensors on the pipeline’s outer wall or parallel side to build an intelligent protection network that is "full-time, full-line, and full-function":

Structure and strain monitoring:Fiber optic strain sensors capture real-time micro-deformations caused by geological subsidence or buckling, with meter-level positioning accuracy to effectively prevent structural damage.

Intelligent Leakage Identification: Temperature-sensing optical cables are deployed at specific locations based on medium characteristics. The system monitors local soil temperature fluctuations caused by leaks, triggering instant warnings for both minor seepage and drastic environmental changes.

Security defense and early warning: The system accurately extracts and identifies vibration signals along the pipeline, distinguishing normal operational noise from threats like mechanical excavation and manual drilling. This allows operators to intervene before damage occurs.

Operation and maintenance resource optimization: The system integrates with existing monitoring platforms for remote management. Based on real-time data, management can dynamically adjust patrol configurations, significantly reducing overall operational costs.

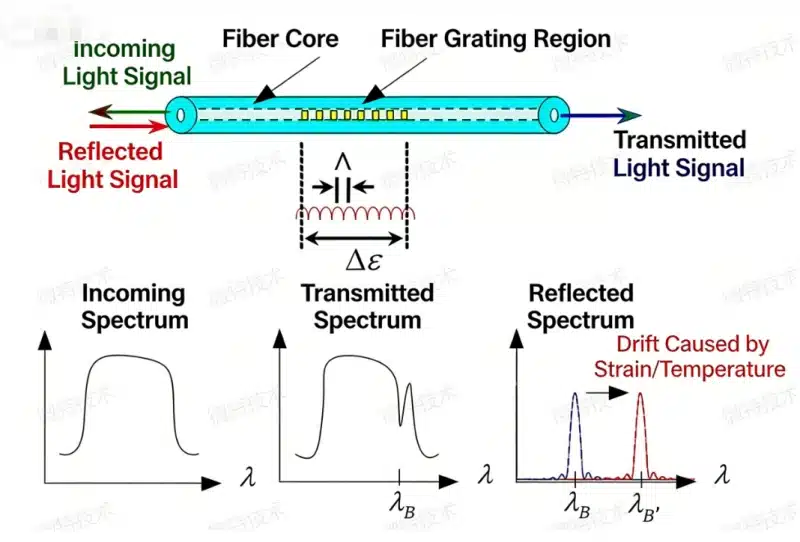

The system’s core is based on distributed fiber optic sensing technology,converting communication fibers into sensitive sensing elements.

Fiber Bragg grating (FBG) demodulation: Ultra-weak gratings with reflectivity below 0.1% are inscribed on the fiber. Photoelectric signal processing analyzes reflected wavelength shifts, converting them into precise stress and temperature data.

Distributed Vibration/Acoustic Sensing (DAS/Φ-OTDR): Light transmission generates Rayleigh scattering. External vibrations or sound fields cause micro-deformations in the fiber core, altering scattered light phase. DAS reconstructs sound field frequency, phase, and amplitude, sensitively capturing subtle disturbances kilometers away.

Intrinsically safe background: Fiber optic sensors resist electromagnetic interference, require no electrical conduction, and have a 30-year lifespan, perfectly meeting the oil and gas industry’s extreme requirements for explosion-proofing, anti-static protection, and high reliability.

Full-Line Blind-Spot-Free Monitoring: A single system covers tens of kilometers of pipelines with continuous sensor nodes, realizing "every meter of fiber is a sensor".

Multi-Parameter Collaborative Sensing and Identification: Simultaneously monitors temperature, stress, vibration, and other multi-dimensional data. Intelligent algorithms eliminate interference, drastically reducing false alarms and improving warning accuracy.

High-Precision Positioning and Response:The system offers exceptional spatial resolution, quickly locating abnormal coordinates to save critical time for emergency response.

Superior Anti-Interference and Weather Resistance: Intrinsically safe fiber material is unaffected by lightning, electromagnetism, or chemical corrosion, operating stably long-term in harsh industrial environments like polar regions and deserts.

Intelligent Remote Management and Control: Supports cloud access and digital modeling. Continuous predictive maintenance extends pipeline service life, aligning with modern green, low-carbon energy management concepts.

Previous: WS-W660 Crane Automatic Lubrication System

Next Article:Online monitoring and fault diagnosis system of machine pump »