1. Product introduction

WSTA-HDVS(800) Y-shaped ladle trunnion video surveillance system is an industrial-grade intelligent monitoring solution independently developed by micro-technology for the safety pain points of ladle lifting operations in the steel industry. The product focuses on the visual control of the whole process of ladle trunnion hooking/decoupling, and integrates core technologies such as high-precision positioning, AI visual recognition, and extreme environment adaptation to provide three simultaneous real-time monitoring capabilities for the driving, finger hanging room, and main control room to avoid operational risks from the root cause and help steel companies realize lifting operations.The intelligent and safe upgrade.

Core advantages

-

Industrial-grade scenario adaptation: designed for high temperature, dust, strong interference, and multi-condition environments in the steel industry, the stability of the equipment has been rigorously verified;

-

AI intelligent empowerment: integrate self-developed visual recognition and tracking algorithms to realize automatic control such as board hook placement determination and hook tracking.;

-

Visualization of the whole process: covering the key stations and operation links of ladle lifting, eliminating blind spots in the line of sight, and realizing "synchronization of three places and full control”;

-

Safe and reliable design: it has multiple safety mechanisms such as high temperature protection, dustproof, power-off and pneumatic protection to ensure the safety of equipment and personnel.

2. Four core solutions

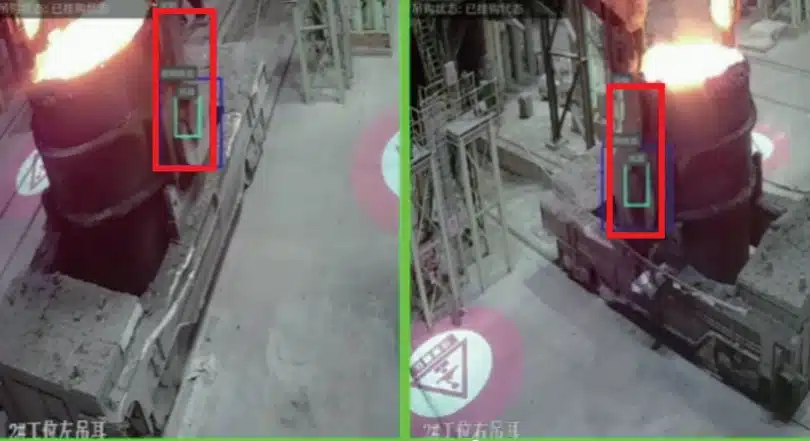

A. Trunnion video surveillance system

Application scenario

It is suitable for key stations such as iron ladles, irrigation stations, desulfurization stations, steel outlet stations, rotary platforms, etc. that need to be fixed for hook/decoupling operations, covering the core monitoring area on both sides of the ladle trunnion.

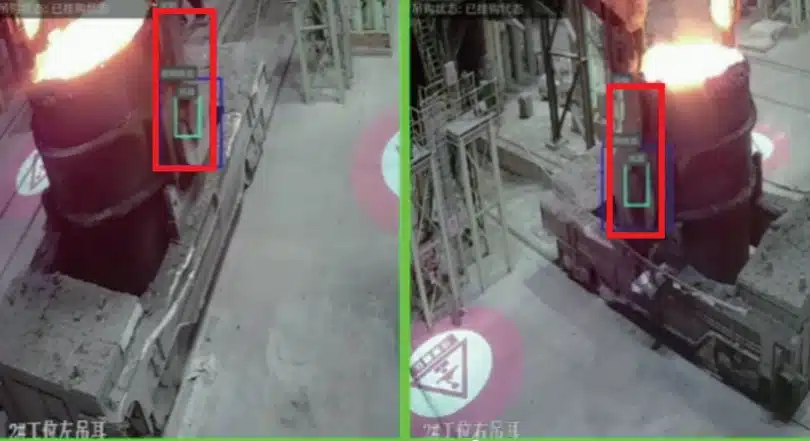

Technical principle

Using the collaborative architecture of "dual camera + high-precision positioning + AI visual analysis", directional cameras are deployed on both sides of the station (the line of sight focuses on the left and right areas of the ladle trunnion), and positioning detection devices are installed on the station and the driving vehicle at the same time. When the driving reaches the preset range of the target station, the system automatically triggers the video signal switching, and the terminals of the driving, finger hanging room, and main control room simultaneously display the real-time screen of the station camera, combined with AI algorithms to achieve intelligent determination of the operation status.

Core functions

-

It integrates a high-precision positioning system and AI image processing technology to accurately determine the completion status of the crane board hook in position.;

-

Intelligent identification of the fit relationship between the trunnion of the ladle and the hook, and real-time push-in status reminders such as qualified/unqualified status;

-

Equipped with an AI model of self-trained visual recognition of the hook to ensure the recognition accuracy in complex environments;

-

It supports the camera's built-in visual following algorithm or an external edge computing processor to achieve accurate tracking of the movement trajectory of the hook.

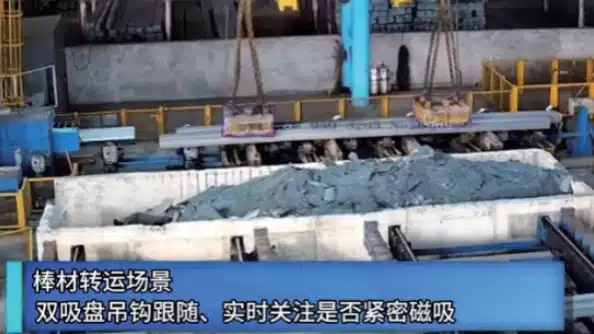

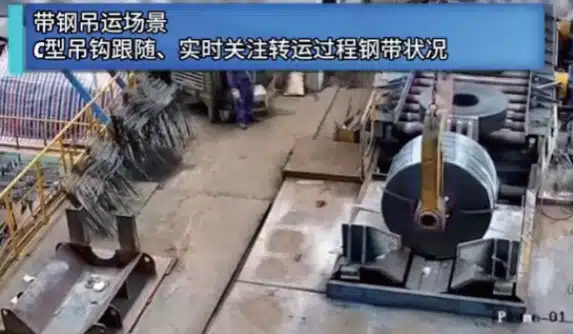

B. Hook automatic tracking video system

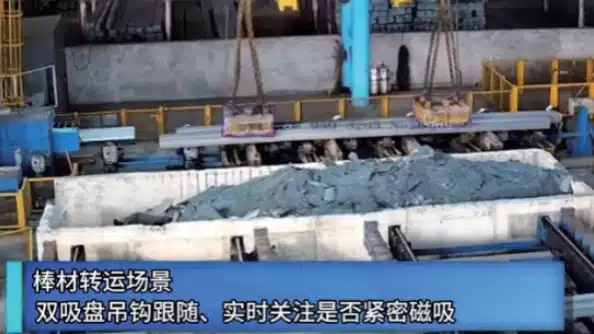

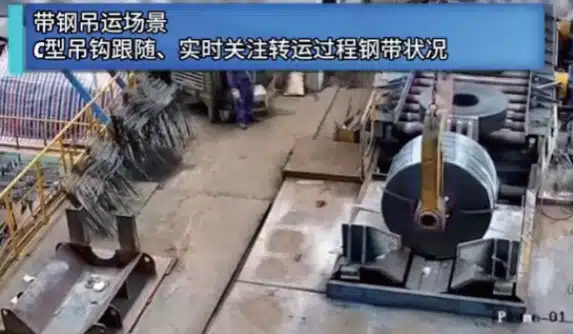

Application scenario

It is suitable for all kinds of driving and hoisting operation scenarios, especially for the complex hoisting needs of the hook with a wide range of movement and a variety of operating perspectives, and assists the driver to accurately control the state of the hook hanging ears.

Technical principle

An AI intelligent tracking camera is installed on the outside of the beam of the vehicle. Based on deep learning image recognition and dynamic tracking algorithms, the camera automatically locks the hook target and dynamically adjusts the focal length and viewing angle during the operation of the vehicle, and transmits high-definition operation pictures to the driving terminal in real time.

Core functions

-

Dynamically and stably track the hook, automatically adjust the shooting angle, and always maintain the best visual viewing angle;

-

The intelligent zoom adjustment function can enlarge the details of the hanging ears that are difficult to recognize by the naked eye and improve the accuracy of the operation.;

-

Independently developed an AI algorithm for determining the stability of the hook and tracking its trajectory to assist the driver in quickly making decisions about the operation of the hook.;

-

Compatible with a variety of hook types, including C-shaped hooks, gantry hooks, special spreaders, etc., to meet the needs of multi-scene operations.

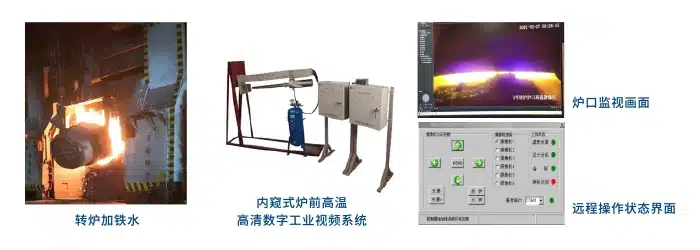

C. Endoscopic high temperature video system in front of the furnace

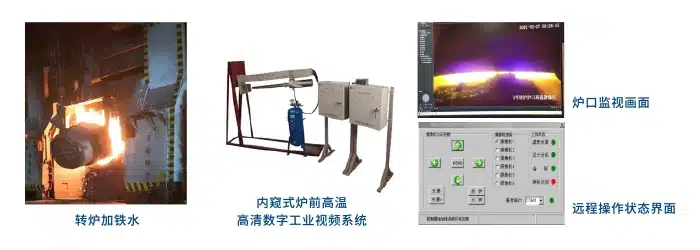

Application scenario

In view of the monitoring needs of the working conditions in the furnace of steelmaking converters, electric furnaces and other equipment, it solves the problem of observing the degree of flame and molten steel refining in the furnace under the risk of high temperature, splashing, and explosion during the feeding and smelting stage.

Technical principle

The system adopts the design of ”endoscopic telescopic structure + composite cooling + strong light suppression". The lens is equipped with sapphire wear-resistant and scratch-resistant material, equipped with a scroll cooler and a three-stage air-cooled composite cooling system, combined with the dust-proof technology of the sweeping wind curtain, it can work stably in an extremely high temperature environment of 2000℃. Through the pneumatic drive mechanism, the lens vision/close-up switching is realized, and the pneumatic protection is automatically triggered when the air is cut off, and the lens is withdrawn from the high temperature area to ensure the safety of the equipment.

Core functions

-

Super strong light suppression technology, which clearly presents the details of the working conditions such as the flame and molten steel liquid level in the furnace, and is not disturbed by strong light;

-

Low-latency remote control, the operation room in front of the furnace can control the lens telescopic and focusing from a long distance to achieve non-contact monitoring;

-

Pneumatic protection mechanism, automatically exits the high temperature environment when there is an accidental power failure, and extends the service life of the equipment;

-

The windshield and dustproof design are purged to ensure the cleanliness of the lens, the clarity of the picture and the smoothness of the expansion and contraction of the equipment.

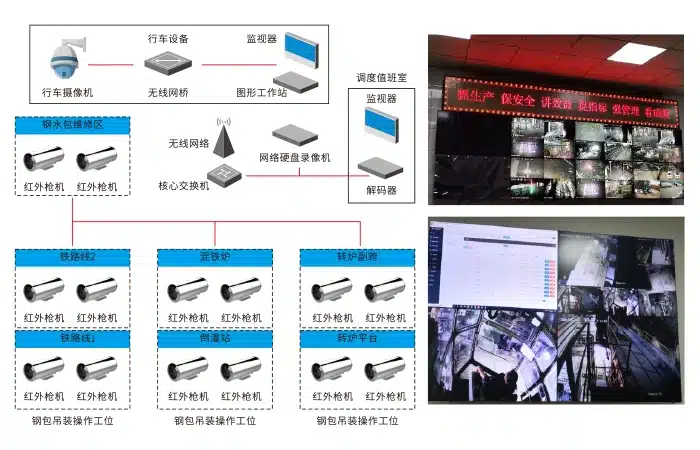

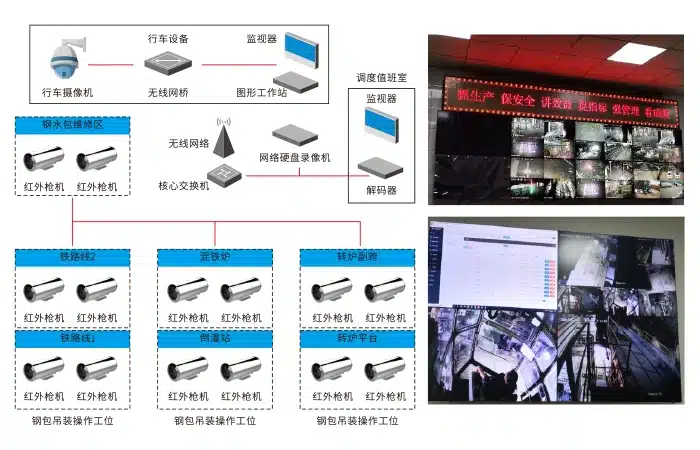

D. Station video remote centralized control system

Application scenario

It is suitable for the centralized management needs of multi-driving and multi-station large-scale steel enterprises, and realizes cross-regional collaborative monitoring and intelligent management of driving, pointing room, and main control room.

Technical principle

Build a high-speed and stable industrial-grade wireless local area network to realize real-time transmission and synchronous sharing of video signals from three places. The main control room deploys core servers and video management software, with video walls and decoders, which can centrally control, retrieve and visualize historical data and visualize traffic monitoring points in the entire factory area.

Core functions

-

Support simultaneous real-time display of video from the driving, finger hanging room, and main control room to ensure the consistency of operation coordination;

-

It has historical video query and playback functions, and supports multi-dimensional indexing by time, device number, IP address, etc.;

-

The video wall supports screen segmentation, stitching, rotation inspection, and group display, and can centrally present surveillance images of key locations of each device.;

-

Support system expansion and secondary development, and adapt to the needs of intelligent factory upgrading.

3. Success stories

Case 1: Video surveillance project of Hoisting ladle station of Minguang Iron and Steel Metallurgical Industry in Quanzhou, Fujian

Fujian Quanzhou Minguang Iron and Steel Co., Ltd. is a core subsidiary of Sangang Group. It is a large-scale metallurgical joint enterprise integrating sintering, ironmaking, steelmaking, continuous casting and rolling. It employs more than 2,800 people and covers a total area of 2,072 mu. Its metallurgical cranes undertake key lifting tasks in the production process.

In order to solve the safety hazards such as blind spots in the line of sight and command coordination deviations in lifting operations, and improve production efficiency, Quanzhou Minguang chose to reach a secondary cooperation with micro-technology to install a WSTA-HDVS(800) Y-shaped metallurgical crane ladle station video system for 6 main metallurgical cranes.

During the implementation of the project, micro-technology combined with the actual working conditions of Quanzhou Minguang steelmaking workshop to deploy trunnion video surveillance and remote centralized control solutions in a targeted manner. The system relies on core functions such as real-time monitoring, dynamic display, sound and light alarm, data backup, password protection, etc., as well as strong anti-interference and operation interface.The advantages of friendly and highly versatile products effectively solve the safety control problems in the ladle lifting process.

After the project successfully passed the acceptance and was put into use, the safety and efficiency of the metallurgical crane operation of the plant were significantly improved, and it was highly recognized by customers, laying a solid foundation for the subsequent deepening of cooperation between the two sides.

Case 2: AI intelligent identification system project for ladle hanging ears of a steel company in Hebei

In response to the needs of the intelligent transformation of the steel industry and improving the safety and operational efficiency of ladle hoisting, a large steel company in Hebei has reached a cooperation with micro-technology to introduce an AI intelligent identification system for ladle hanging ears. The project focuses on the safety control of the whole process of metallurgical driving ladle hoisting, integrating driving positioning system, video acquisition technology, AI analysis and determination technology and wireless transmission technology to form an integrated intelligent solution.

After the system is deployed, accurate position perception is achieved through driving positioning. With the help of high-definition cameras, the real-time picture of the board hook hanging ear is captured, and the state of the hanging ear is determined by the AI algorithm, and the real-time video and the judgment result are synchronized to the driving cab, which effectively expands the driving staff's operating field of vision and completely solves the visual blind spots in the cab.problem. At the same time, the system can accurately judge the situation of the plate hook hoisting in place, and avoid safety accidents such as ladle falling off due to improper hoisting of the hook from the root cause. On the basis of ensuring operation safety, the efficiency of ladle hoisting has been greatly improved and the rate of human operation errors has been reduced.

In addition, the system also realizes intelligent monitoring and coverage of the whole process of metallurgical driving ladle and ladle hoisting, from the state of double-plate hook hook and off-hook cooperation, to the dynamic trajectory of ladle hoisting and the attitude of sitting on the bag, can be tracked in real time and clearly presented. The successful landing of the project is the customer's high recognition of the innovation ability of micro-technology, the strength of customized solutions and the spirit of professional service. It has also become an important practice for the two sides to jointly promote the high-quality and intelligent development of the iron and steel metallurgical industry.

4. Summary of product value

The WSTA-HDVS(800) Y-shaped ladle trunnion video surveillance system deeply fits the high-temperature, high-risk, and high-complexity operating characteristics of the steel industry, and builds a full-scene visual control system for lifting operations through the “four core solutions”. With AI intelligent technology as the core, industrial-grade reliability as the basis, and multi-terminal collaboration as the support, the system provides steel companies with ”safe, controllable, accurate, efficient, intelligent and convenient" video surveillance solutions to help them reduce the incidence of safety accidents, improve operational efficiency, and promote the intelligent transformation of production.Practice the corporate mission of "making lifting operation safer and management more efficient".