Product introduction: Based on independently developed magnetic sensors and international standard magnetic memory flaw detection principles

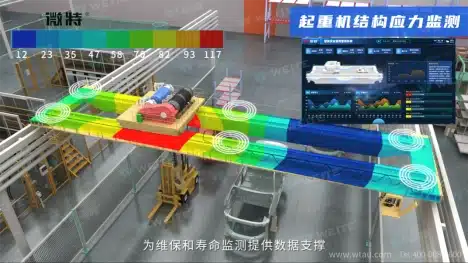

During the operation of hoisting equipment, problems such as structural stress overload and fatigue damage are likely to cause equipment failures and even safety accidents. The traditional manual detection mode cannot realize real-time stress monitoring and early hidden danger warning. Relying on structural mechanics, sensor technology and intelligent algorithms, WTAU Technology has developed theCrane Structural Stress Online Monitoring and Life Assessment System.Integrating fiber Bragg grating sensing technology, finite element analysis and load stress spectrum analysis, the system achieves real-time monitoring, intelligent early warning, health evaluation and accurate life assessment of the structural stress of hoisting equipment, provides scientific data support for equipment maintenance decision-making, effectively prevents sudden failures and prolongs the service life of equipment, complying with the national design and safety specifications for cranes.

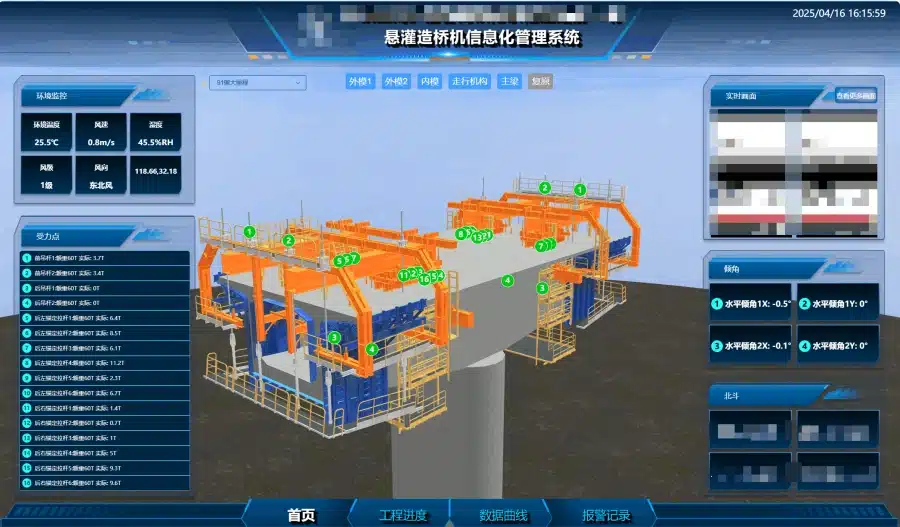

The Crane Structural Stress Online Monitoring and Life Assessment System is an intelligent monitoring solution developed by WTAU Technology for the structural safety pain points of hoisting equipment. Designed and manufactured based on the calculation principles of structural stress and material strength, it can real-time capture the stress data of key stress-bearing parts such as the main jib, main beam and pull rod of gantry cranes, bridge erecting machines, overhead/gantry cranes and other equipment under different loads, and synchronously display multi-dimensional information such as equipment operating environment, inclination angle and stress load.

According to the preset safety range, the system can issue accurate early warning prompts for risks such as structural stress overload and fatigue damage. At the same time, it supports the storage, export and trend analysis of monitoring data, and conducts professional evaluation on the health of core structures such as the main beam and main jib of the equipment in combination with finite element analysis and load stress spectrum, realizing the upgrade of equipment management from "passive maintenance" to "active prevention". It is widely applicable to the structural stress monitoring scenarios of various hoisting equipment and gate structures in the fields of bridge engineering, port terminals, water conservancy and hydropower, etc.

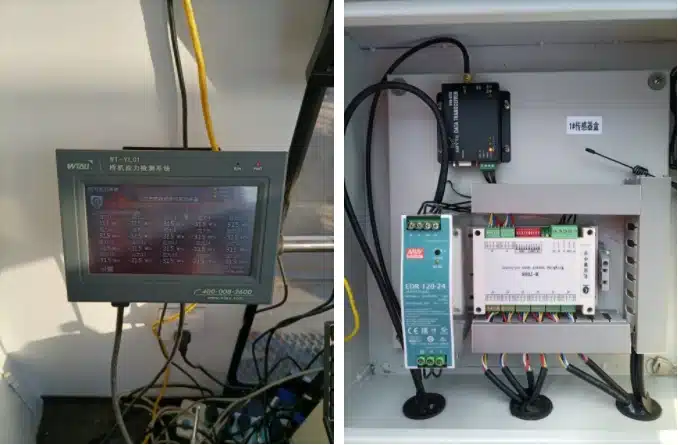

Equipped with high-precision sensing equipment and data acquisition modules, the system real-time monitors the stress/strain data of key stress points of the equipment, and synchronously collects multi-parameter information such as ambient temperature, wind speed, humidity and equipment horizontal inclination angle. All data are visually displayed through the main frequency display, clearly presenting the rated load and actual load values of each stress-bearing part, making the equipment operating status clear at a glance.

Based on the national crane design specifications, the structural stress safety threshold is preset. When parts such as the main jib, main beam and pull rod of the equipment have stress overload and exceed the safety range, the system immediately issues an early warning prompt, timely detects hidden dangers of early fatigue damage, and avoids equipment failures and safety accidents caused by structural stress problems from the source.

The system has large-capacity data storage capacity, which can long-term save all operating data such as stress monitoring, load changes and environmental parameters, and supports one-click export and multi-dimensional query of data. Through the trend analysis of historical monitoring data, the change law of equipment structural stress is accurately captured, providing data basis for judging the degree of structural fatigue damage.

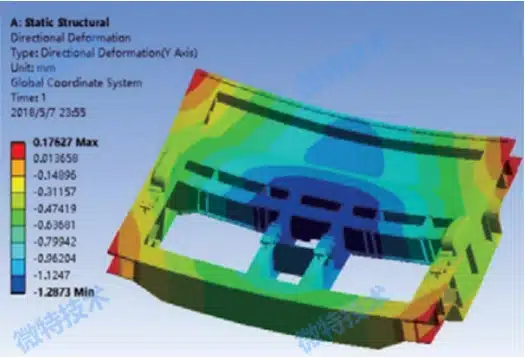

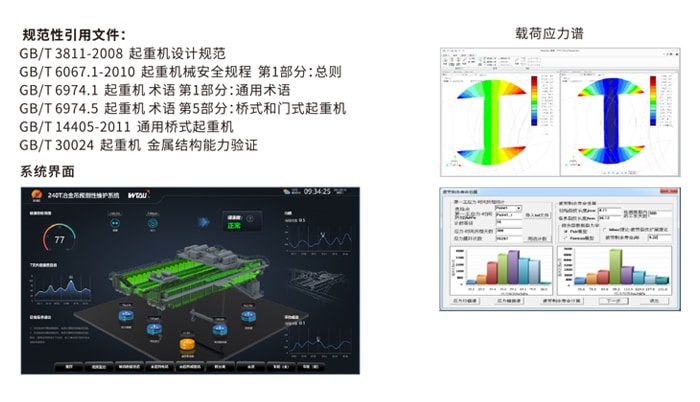

Integratingfinite element analysisandload stress spectrumanalysis technology, the system conducts professional evaluation on the health of core structures such as the main beam and main jib of the equipment, and realizes accurate assessment of the remaining service life of the equipment in combination with the long-term structural stress monitoring data, providing scientific decision-making support for formulating personalized maintenance, overhaul and replacement plans for the equipment.

The system is not only suitable for the stress monitoring of various hoisting equipment, but also can be expanded to the structural stress monitoring of water conservancy gates, creating an integrated structural stress monitoring solution for cranes and gates to meet the structural safety monitoring needs of equipment in multiple fields.

With fiber Bragg grating sensing technology as the core, combined with hardware equipment such as WT-MOD acquisition module and main frequency display, and integrated with photoelectric signal processing, demodulation technology and structural mechanical analysis methods, the system realizes distributed, real-time and high-precision monitoring of equipment structural stress. The core technical principles are as follows:

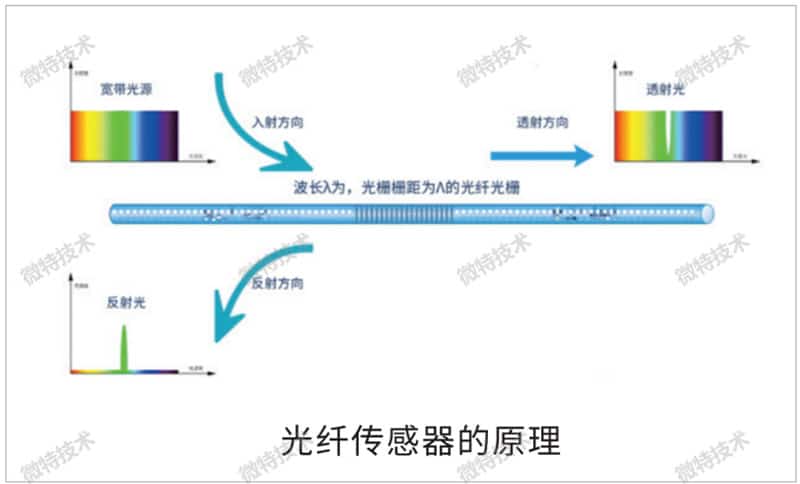

1.Fiber Bragg Grating Array Sensing:Fiber Bragg grating sensors are made of low-loss photosensitive optical fibers. Multiple induction sensors are connected in series, and the bare fibers are exposed before coating during the wire drawing process. Hundreds to thousands of weak gratings are written in a single optical fiber to form a fiber Bragg grating array, which can realize multi-measurement point and distributed stress sensing.Information system of suspension bridge-building machine.

2.Optical Signal Reflection and Acquisition:The laser pulse emitted by the broadband light source propagates forward along the optical fiber. When the equipment structure deforms, the ultra-weak grating sensor array on the optical fiber deforms synchronously and partially reflects the laser. The reflected light returns to the acquisition host back along the original optical fiber to realize real-time signal capture.Portal Crane Safety Monitoring System.

3.Photoelectric Signal Processing and Analysis:Through photoelectric signal processing and demodulation technology, the acquisition host analyzes and processes the reflected light signal, accurately extracts multi-parameter information such as temperature, stress/strain, deformation and vibration of the engineering structure, and realizes real-time monitoring of the detected object.Online monitoring system of gate/hoist.

4.Comprehensive Analysis of Structural Health:The real-time stress data collected by the sensing equipment is combined with finite element analysis and load stress spectrum, and the fatigue damage degree and health status of the equipment structure are quantitatively evaluated through professional algorithms, and finally the accurate assessment of the equipment life is realized.Crane Safety Monitoring System.

This system is based onFiber grating sensing technologyAs the core, with WT-MOD acquisition module, frequency display and other hardware equipment, combined with photoelectric signal processing, demodulation technology and structural mechanics analysis methods, to achieve distributed, real-time and high-precision monitoring of the structural stress of the equipment, the core technical principles are as follows:

The fiber grating sensor has the characteristics of simple production, small size and good stability, and is anti-electromagnetic interference and flexible in use. It can be integrated with optical fiber to form a monitoring network, which is perfectly adapted to the complex operating environment of industrial sites.

Using distributed fiber grating sensing technology, the stress data of key force points is accurately captured, and multi-dimensional information such as environment, inclination, and load is simultaneously collected, and the monitoring data truly reflects the operating status of the equipment structure, providing a reliable basis for analysis and evaluation.

Real-time early warning of stress overload is realized based on preset safety thresholds, hidden dangers of structural fatigue damage are discovered in advance, sudden equipment failures caused by stress problems are effectively avoided, and the safety and stability of lifting equipment operation are improved.

Through data trend analysis, finite element analysis and load stress spectrum analysis, an accurate assessment of the structural health and remaining service life of the equipment is completed, and the traditional empirical maintenance model is changed to make equipment maintenance and overhaul decisions more scientific and efficient.

System R&D and design strictly followGB/T3811-2008 crane design specification、GB/T6067.1-2010 Lifting machinery safety regulationsAnd other current national standards, adapted to the standardized management requirements of industry equipment, can be directly applied to the monitoring of various types of compliance lifting equipment.

The fiber grating sensor has excellent anti-electromagnetic interference performance, can work stably in industrial sites with high dust, strong electromagnetism, and vibration, and the equipment is small in size and flexible in installation, which does not affect the original operating process of the equipment.

The monitoring data supports local large-capacity storage and one-click export, and can be connected to the enterprise equipment management platform for secondary analysis to meet the data usage needs of multiple scenarios such as daily equipment operation and maintenance, fault traceability, and life assessment.

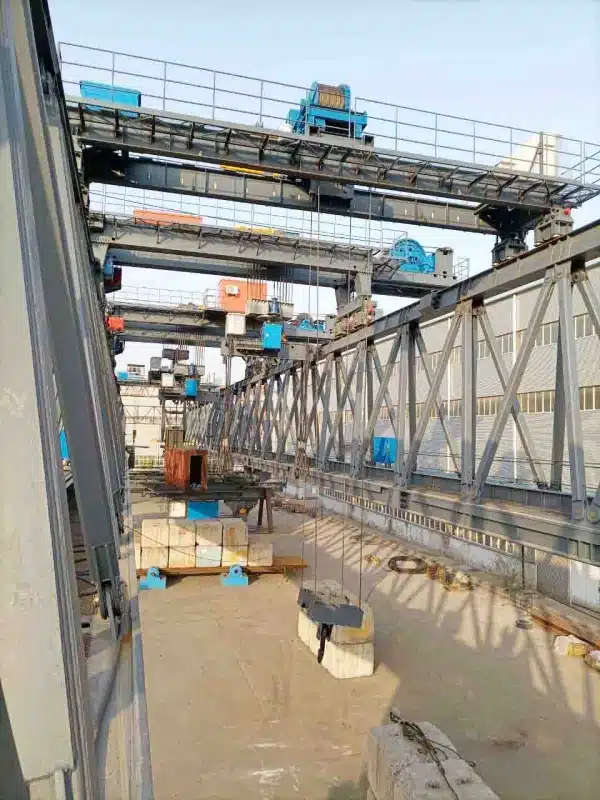

Qinhuangdao Tianye Tonglian Heavy Industry Co., Ltd.

Provided customized stress monitoring solutions for Qinhuangdao Tianye Tonglian Heavy Industry, which were successfully applied to900-ton high-speed railway bridge-building machine、900-ton tire beam truck、900-ton tire type / wheel-rail type beam lifterOnline monitoring of structural stress.

The system accurately captures the stress data of the key force parts of the equipment, feeds back the load changes and stress status in real time, and issues timely early warnings of overload risks, providing a full guarantee for the safe operation of the equipment in the construction of high-speed railway projects. At the same time, through the trend analysis of stress data, it provides a scientific basis for the formulation of equipment maintenance plans, which is effective.The operating efficiency and service life of the equipment are improved.

Previous: Online monitoring and fault diagnosis system of machine pump

Next Article:Chairman Nie Daojing Attends Provincial People’s Congress, Proposes "Little Giant" Enterprises to Boost Innovation Ecosystem »