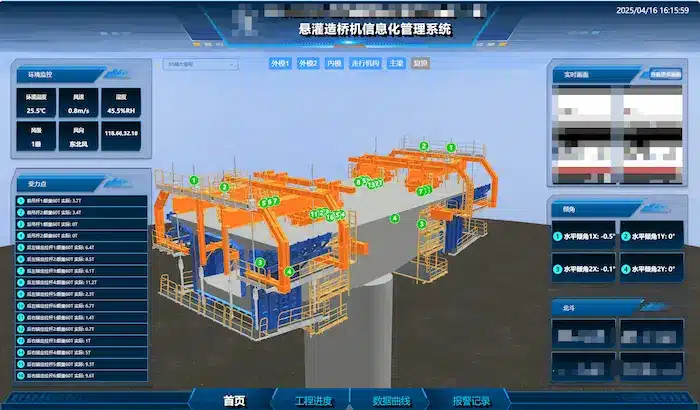

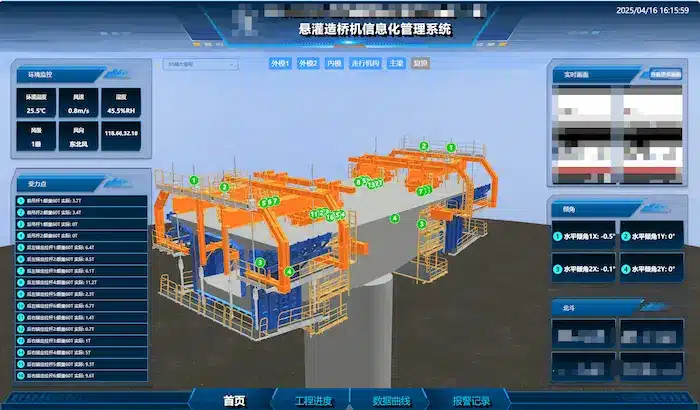

1. Product introduction

The information system of the suspension irrigation bridge construction machine is an integrated intelligent monitoring solution specially designed for modern bridge construction. The system integrates high-precision force sensors, Beidou positioning, structural stress monitoring and video surveillance technologies, etc., to monitor key parameters during the construction process of bridge construction machines in real time, ensuring construction safety and improving project quality, providing comprehensive digital management support for large-scale bridge construction.

2. Industry Pain Points

- Lack of safety supervisionThe traditional hanging basket construction lacks mandatory safety standards and poses significant safety hazards

- The problem of balance controlThe self-weight of the bridge-building machine has increased, and the requirements for construction balance control are extremely high, making it difficult for humans to precisely control

- The construction risks have intensified.The length of the segments keeps increasing (from 4 meters to 8 meters), the construction period shortens, and the risk factor doubles

- The monitoring methods are backwardTraditional construction lacks real-time data collection and early warning mechanisms, relying on manual experience for judgment

- The quality is difficult to trace.The data records during the construction process are incomplete, making it difficult to trace the root cause of quality issues

3. Solutions

By adopting multi-sensor fusion technology, a comprehensive monitoring system is constructed

- Dual balance monitoringThe force sensor is used to monitor the imbalance of the wiring in real time, and the Beidou system monitors the imbalance of the weight pouring

- Multi-parameter acquisitionSynchronously monitor key data such as equipment tilt, traveling distance, structural stress, and environmental parameters

- The video covers the entire processRealize visual monitoring of the construction site and fully record the construction process

- Intelligent Early warning PlatformEstablish a data monitoring center to provide remote monitoring and real-time alarm functions

- Standardized interfaceSupports seamless integration with the engineering management system to achieve data sharing

4. Main Functions

- Real-time balance monitoringHigh-precision monitoring of wiring and pouring balance to prevent overturning risks

- Beidou precise positioningReal-time tracking of equipment location and movement trajectory to ensure construction accuracy

- Structural health monitoringContinuously monitor stress changes in key parts and warn of structural safety hazards

- Environmental parameter collectionMonitor environmental factors such as wind speed and temperature, and provide construction decision support

- Video surveillance systemComprehensive video coverage enables visual management of the construction process

- Data management platformIt provides real-time data display, historical query and report generation functions

- Multi-level alarm mechanismProvide audible and visual alarms and emergency control based on the risk level

- Remote monitoring supportSupports remote real-time monitoring on both PC and mobile terminals

5. Core Advantages

- Industry-leading experienceSince the emergence of bridge-building machine technology, we have been involved in monitoring and research and development, accumulating profound technical expertise

- Integration of multiple technologiesIt integrates multiple monitoring methods such as sensors, Beidou, and video to ensure all-round safety

- Precise monitoring capabilityMillimeter-level monitoring accuracy ensures controllable construction quality

- Enrich project verificationIt has been successfully applied in over a hundred T-structure bridge construction machine projects across the country, and the technology is mature and reliable

- Customized solutionsProvide personalized monitoring solutions based on different engineering requirements

- Continuous technical serviceProvide full-cycle service support from installation and commissioning to operation and maintenance

6. Application Cases

The monitoring project of the first bridge-building machine of the Xiongxin High-Speed Railway

As one of the first bridge-building machine monitoring projects in the industry, we have been deeply cooperating with the design institute

- Monitoring object: Top-bearing suspension irrigation bridge construction machine

- Monitoring parameters: wiring balance, pouring weight, structural stress, etc

- Project achievements: Provide important data support for subsequent standard formulation

Large-scale application of multiple railway lines

It has been successfully applied to important railway construction projects across the country

- Covered lines: More than ten key railways such as Xi-Yan, Yan-Yu, Xi-Cheng, Sichuan-Xizang, and Chengdu-Chongqing Central Line

- Service unit: Has established long-term cooperative relationships with multiple units of China Railway

- Implementation scale: Over a hundred intelligent monitoring cases of T-structure bridge construction machines

Monitoring of large-scale section construction

Support construction monitoring for large sections of 6-8 meters

- Monitoring capability: Supports construction monitoring of large bridge construction machines with 8-meter segments

- Technological breakthrough: Solving the problem of balance control in large-scale section construction

- Engineering benefits: Significantly shorten the construction period and enhance construction efficiency