Core member of the Micro and Special Construction Division

We focus on providing full-cycle services for large infrastructure enterprises such as China Railway Construction Corporation, China Communications Construction Group, PowerChina, Energy Engineering Group, and China Nuclear Engineering & Construction CorporationConstruction equipment safety management and digital management solutionsBased on on-site experience, deeply participate in the technical research and development of key construction nodes.

Part One of the Micro and Special International Business Division

Application value: Reduce the accident rate of group tower operations by 831 to 3T

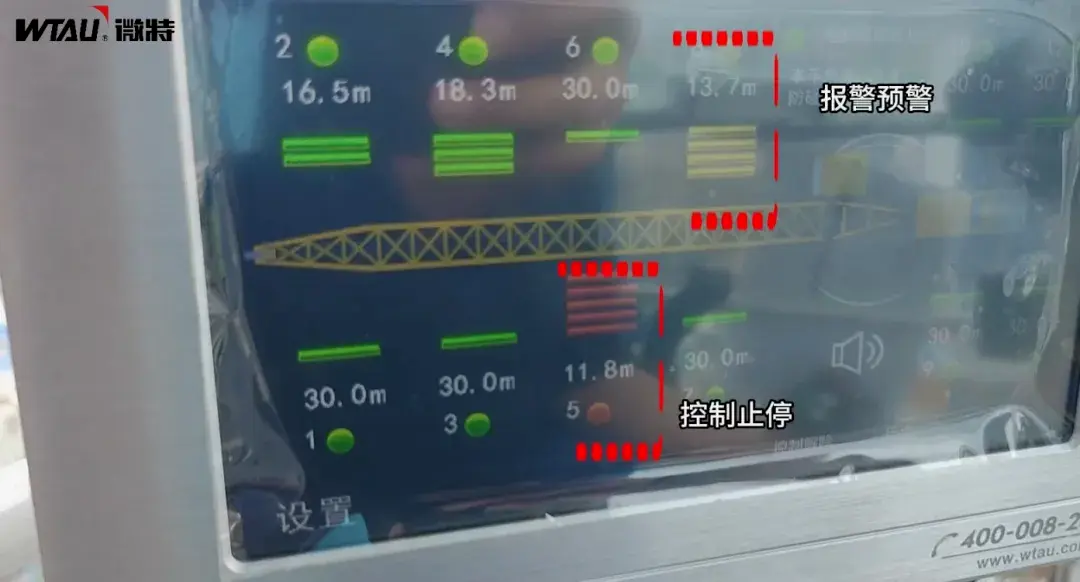

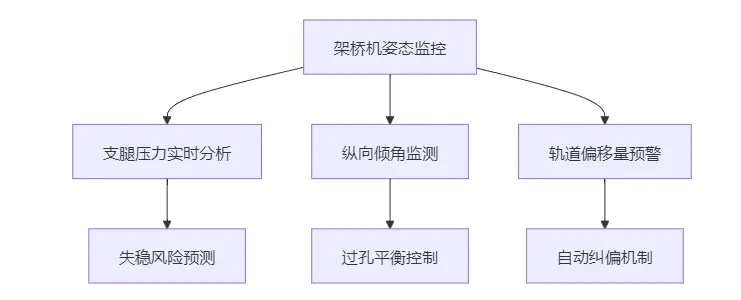

Technological breakthrough: Addressing the pain points of traditional bridge erection machine overturning accidents

| Ability dimension | Implementation case |

|---|---|

| Handling of complex working conditions | Deployment of tower crane monitoring at an altitude of 5,000 meters on the Sichuan-Tibet Railway |

| Rapid response mechanism | Emergency bridge erection machine modification within 72 hours in Xiongan New Area |

| Participation in standard formulation | Participated in the compilation of the "National Standard for Safety Monitoring of Bridge Erection Machines" |

"During the construction of the Shanghai-Nantong Yangtze River Bridge project, the micro-special bridge erection machine monitoring system successfully warned of seven abnormal leg pressure issues, preventing major accidents," reported the Equipment Department of China Railway Major Bridge Engineering Group

FocusThe intrinsic safety of construction equipment has been enhancedWe have provided services for over 300 infrastructure projects and helped our clients achieve:

Next Article:The Weite dynamic weighing system has helped Xiamen Bay Port set a new record for the efficiency of sand and gravel loading »