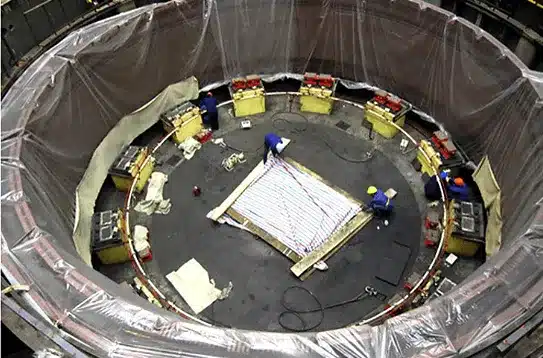

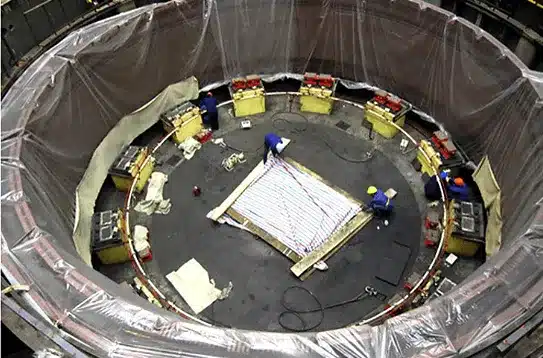

The mechanical braking system is the key equipment in the shutdown process of the hydroelectric generator set, and its operating state is directly related to the safety of the unit. It is difficult for traditional monitoring methods to grasp the displacement status of air brake brakes in real time, and there are safety risks. Online monitoring system for air brake displacementIt came into being, and through accurate monitoring and intelligent analysis of brake displacement, it provides a solid guarantee for the braking safety of the unit.

1. System overview: real-time monitoring, prevention before it happens

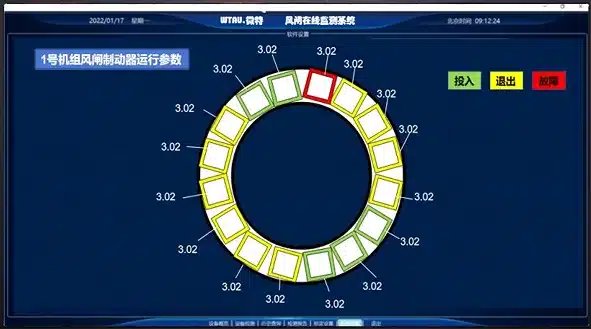

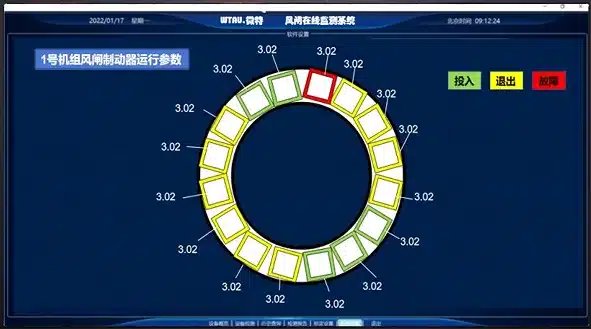

The online monitoring system of air brake displacement is an intelligent monitoring solution specially designed for hydroelectric generator sets. Through a high-precision laser displacement sensor, the system collects the displacement data of the air brake brake in real time, automatically judges the operating status of the equipment, and alarms immediately when an abnormality occurs, effectively preventing mechanical failures and safety accidents caused by abnormal displacement.

2. Core functions: Trinity comprehensive protection

Precise displacement monitoring

- Using a high-performance laser displacement sensor, the measurement range covers ±5mm to±200mm

- The repeatability is up to 10µm to ensure accurate and reliable data

- Monitor the displacement changes of each air brake brake in real time, and fully grasp the status of the equipment

Intelligent early warning mechanism

- Sound and light alarms are triggered immediately when the displacement exceeds the limit, reminding operation and maintenance personnel to deal with it in a timely manner

- Support multi-level alarm threshold setting to meet the needs of different working conditions

- Alarm information is uploaded to the monitoring system in real time to facilitate rapid response

Intelligent judgment of status

- Automatically identify the three-level status of normal, early warning, and fault

- Provide equipment health status assessment based on long-term data analysis

- Support predictive maintenance and turn passive maintenance into active prevention

3. Technical advantages: professional design to ensure reliable operation

High-precision measurement

The laser displacement sensor equipped with the system has excellent performance:

- Measuring center distance: 30mm to 400mm, multiple specifications are available

- Repeatability: 10µm to 800µm to meet different accuracy requirements

- Environmental adaptability: Working temperature -10℃~+40℃, protection level IP67

Stable and reliable

- Industrial-grade components are used to ensure long-term stable operation

- Support 12~24V wide voltage power supply, adapt to the complex environment of power stations

- With short circuit protection function, enhance system reliability

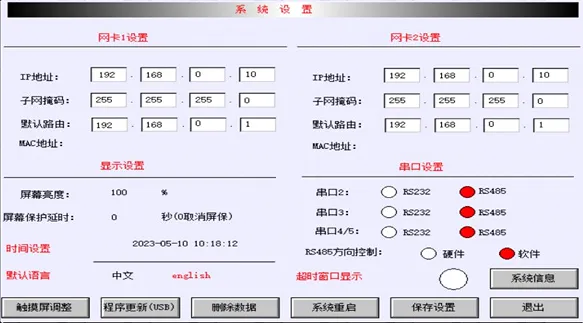

Easy to integrate

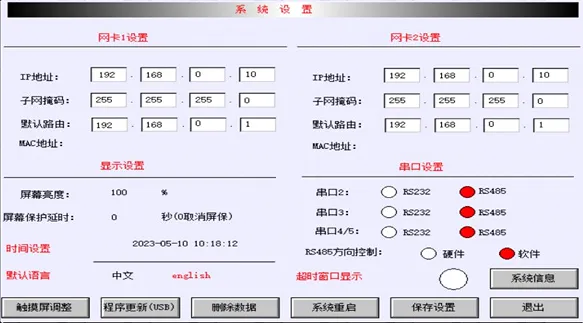

- Standard Modbus communication protocol, easy to interface with existing systems

- Support 4~20mA analog output, compatible with a variety of acquisition devices

- Modular design, easy installation and maintenance

4. Application value: improve the level of safety management of power stations

The application of on-line monitoring system of wind brake displacement brings significant benefits to hydropower stations:

Security upgrade

- Grasp the working status of air brake brakes in real time and find abnormalities in time

- Effectively prevent safety accidents caused by brake system failure

- Add a reliable technical line of defense for the safe operation of the unit

Operation and maintenance efficiency improvement

- Reduce the workload of manual inspection and reduce labor intensity

- Accurate judgment based on data to improve the scientific nature of maintenance decision-making

- Extend the service life of equipment and reduce overall maintenance costs

Advanced management level

- Realize the transition from ”post-mortem maintenance” to ”predictive maintenance”

- Establish a complete equipment status file to lay the foundation for refined management

- Improve the level of intelligence of power stations and conform to the development trend of the industry

The online monitoring system of air brake displacement reflects our technological accumulation and innovative spirit in the field of safety monitoring of hydropower equipment. We will continue to be committed to the development of advanced monitoring technologies and solutions to provide strong support for the safe, stable and efficient operation of hydropower stations, and help China's hydropower industry move towards a new level of intelligence.