1. The core pain points of the application of anchoring machine / winch machine

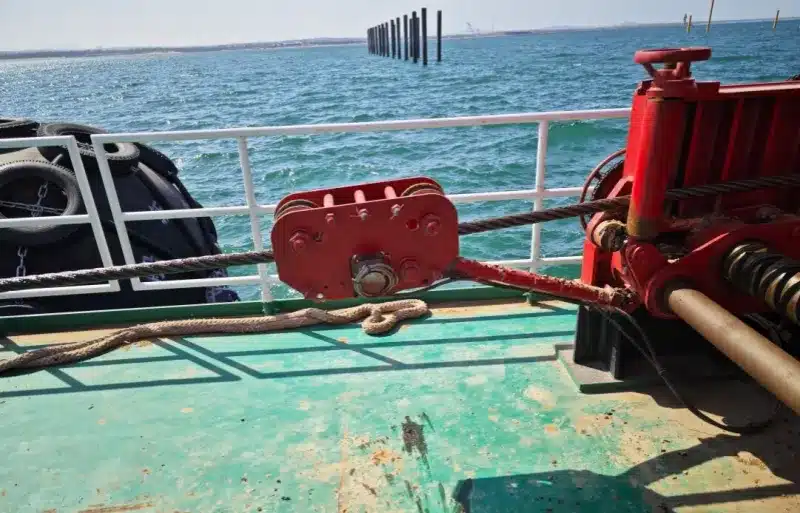

In the process of anchoring, berthing and operation of large-scale engineering ships, floating cranes, tankers and other equipment, the operation safety of anchorages and winches faces multiple risks, and the core pain points are concentrated as:

- Risk of tension out of control: When the ship is displaced due to strong winds, tides, and cargo loading and unloading, the cable is subjected to uneven force, which is prone to local tension overload. Manual visual inspection is difficult to accurately control in real time, which may cause cable fracture and damage to the anchor structure.;

- Safety hazards of over-torque: When the brake braking torque is abnormal or the operating load exceeds the carrying range of the equipment, there is a lack of real-time monitoring and intervention mechanism, which can easily cause major accidents such as anchor stagnation, gear box damage, and even ship drift and collision.;

- Unattended control blind spot: Scenes such as anchorages and barges need to be unattended for a long time. It is difficult for traditional manual inspections to cover 24-hour real-time monitoring, and problems such as cable relaxation and abnormal tension cannot be found in time.;

- Missing data traceability: The lack of continuous recording of key data such as cable tension and retractable length makes it difficult to trace the cause after equipment failure, which is not conducive to the optimization of operating processes and the definition of safety responsibilities.

2. Product introduction

WT-SHL type anchoring machine, cable winch monitoring system, is an industrial-grade real-time monitoring and protection system developed by micro-technology for the safety pain points of anchoring and winching rigs. The core model isWT-SHL-##t(“##t" represents the corresponding tension specification). The system takes "real-time monitoring, active early warning, and controllable protection” as the core design logic. It can accurately collect the traction and braking torque data of the winch, trigger sound and light alarms when the load is overloaded, and release part of the torque in a planned manner under over-torque conditions, from the root cause.Avoid safety accidents such as cable breakage, anchor damage, and ship drift; at the same time, it has a real-time monitoring function of cable length to provide accurate data support for anchoring and berthing operations.

The core parameters of the system meet strict industrial-grade standards:

- Material: The main body is made of 304 stainless steel or iron, and the surface is sprayed or painted to resist corrosion and harsh environments.;

- Tensile force measurement range:5t-500t, Adapt to the needs of different tonnage anchorages /winches;

- Applicable range of steel cable: 25-60mm, compatible with mainstream cable specifications;

- Length measurement range: maximum 10,000 meters, the measurement method adopts absolute encoder, the data is accurate and there is no cumulative error.

3. Main functions

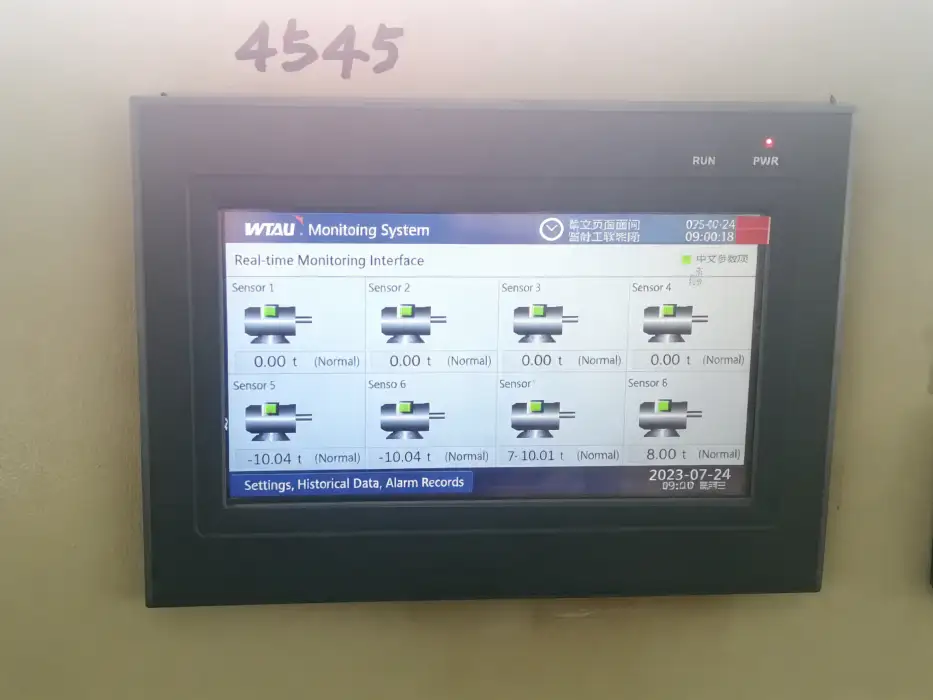

- Real-time tension monitoring and overload alarm: Real-time collection of cable traction and braking torque data through high-precision tension sensors, and synchronous transmission to on-site monitoring instruments and remote monitoring centers; when the tension exceeds a preset safety threshold, the system immediately triggers a sound and light alarm, and at the same time a pop-up window prompts in the monitoring terminal to remind the operator to intervene in time.

- Real-time cable length monitoring: Relying on the length measuring sensor composed of absolute encoder, the length of the cable retracted and retracted is recorded in real time, and the data accuracy has no cumulative deviation. The current length of the cable released/retracted can be clearly displayed in the local instrument and monitoring center, so as to avoid problems such as excessive anchoring and excessive berthing due to inaccurate cable length control..

- Super torque controllable release protection: For dangerous over-torque conditions, the system has the function of "planned brake release”-not disordered release: when the brake braking torque is monitored to exceed the carrying limit of the equipment, the brake can be slowly released through a preset program, and part of the torque can be gradually released to avoid cable bounce and equipment impact caused by a sudden drop in torque, and to ensure that the braking torque exceeds the carrying limit of the equipment.Safety of anchors, cables and ships.

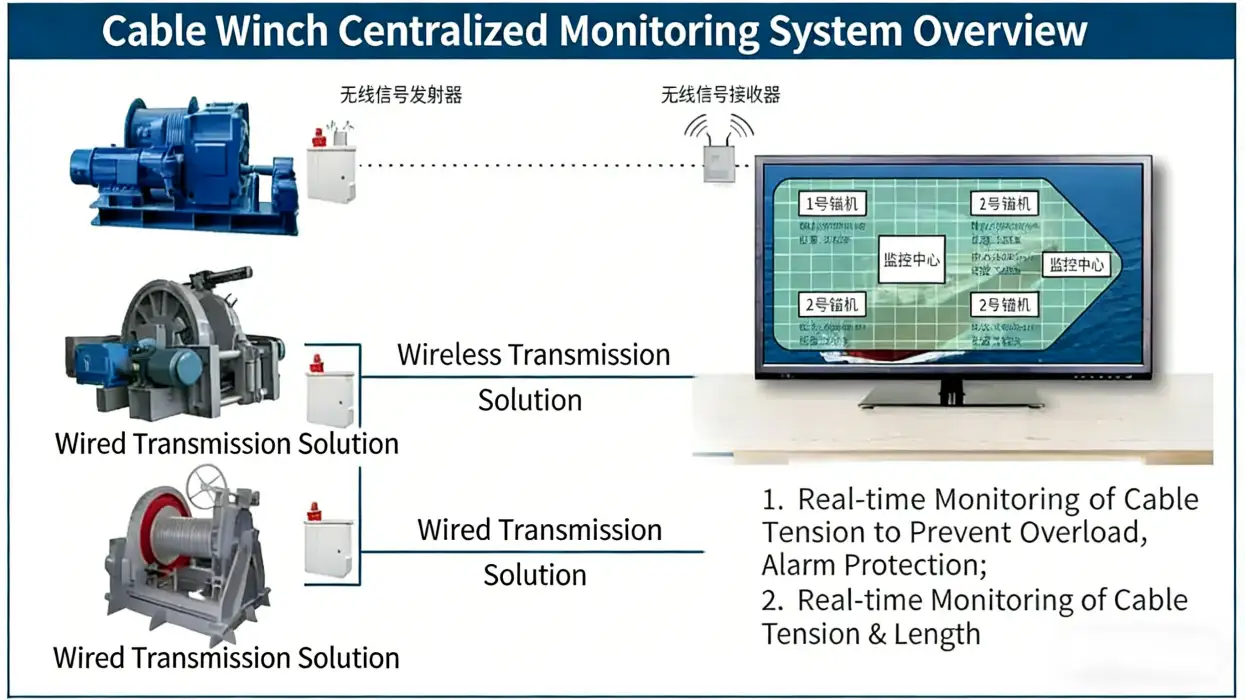

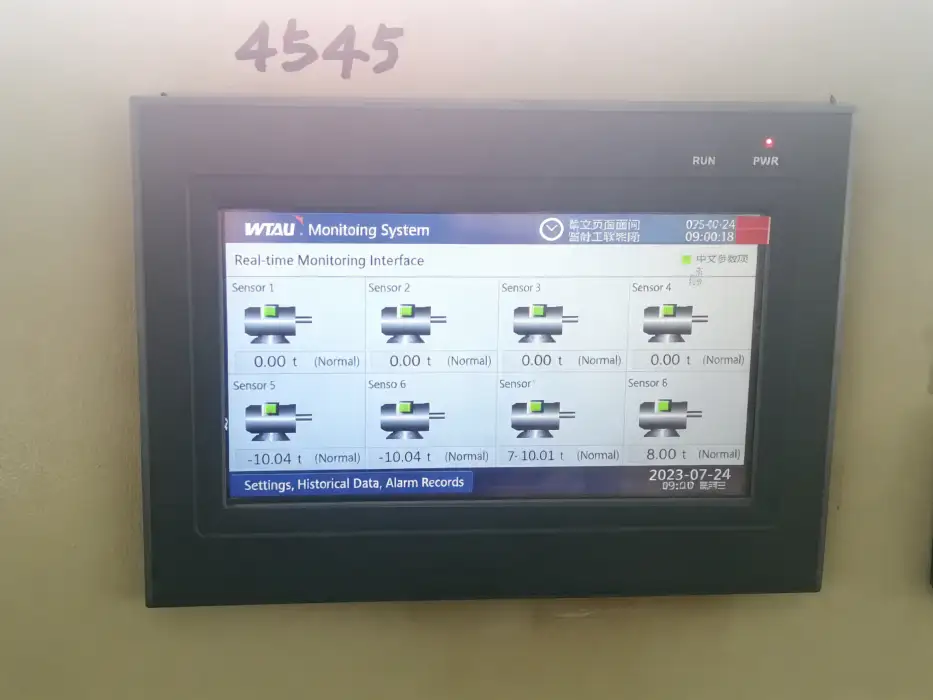

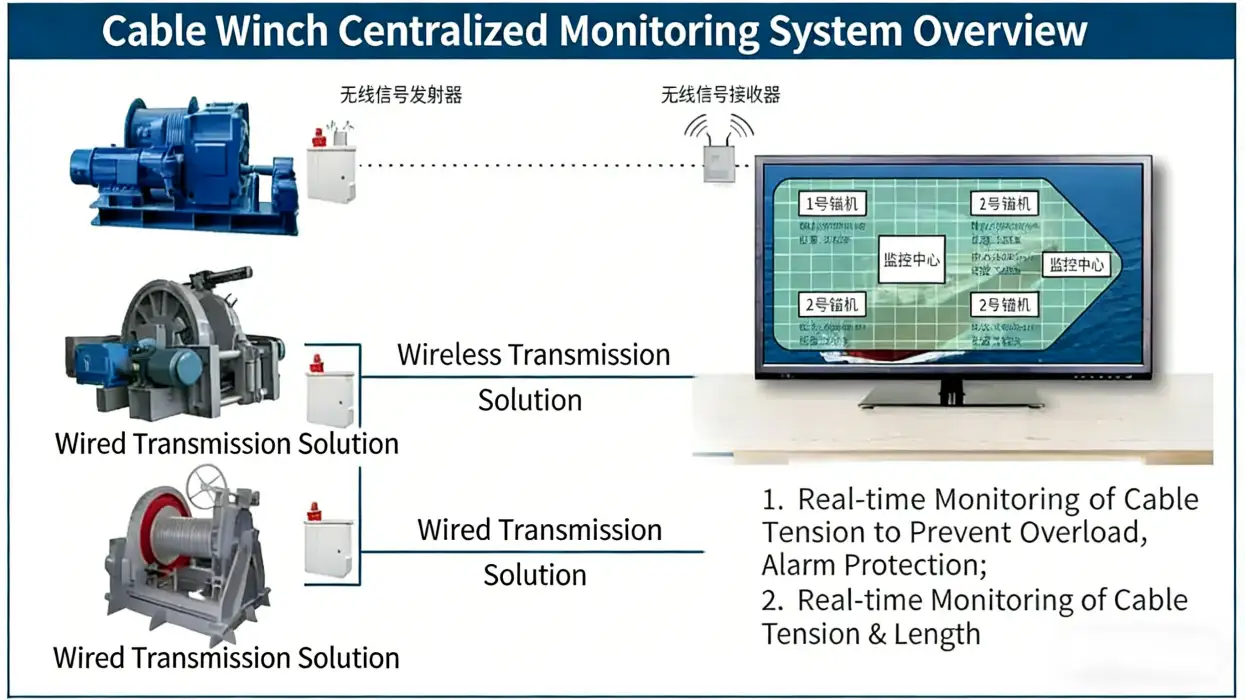

- Multi-terminal centralized monitoring and data transmission: Supports two transmission schemes, wired and wireless. The wireless scheme realizes remote data transmission through “wireless signal transmitter + receiver” and is adapted to mobile operation scenarios; the wired transmission module (industrial cable) is adapted to fixed operation scenarios and has strong anti-interference ability; on-site monitoring instruments, underground centralized control centers, and ground monitoring platformsTension and length data can be obtained synchronously, and integrated “local + remote” control can be realized to meet the real-time monitoring needs in unattended scenarios.

- Data storage and traceability: The system automatically stores key data such as tension, length, and alarm records, supports querying historical data by time, equipment number and other dimensions, and provides reliable data support for operation safety analysis, equipment failure traceability, and process optimization.

4. Application field

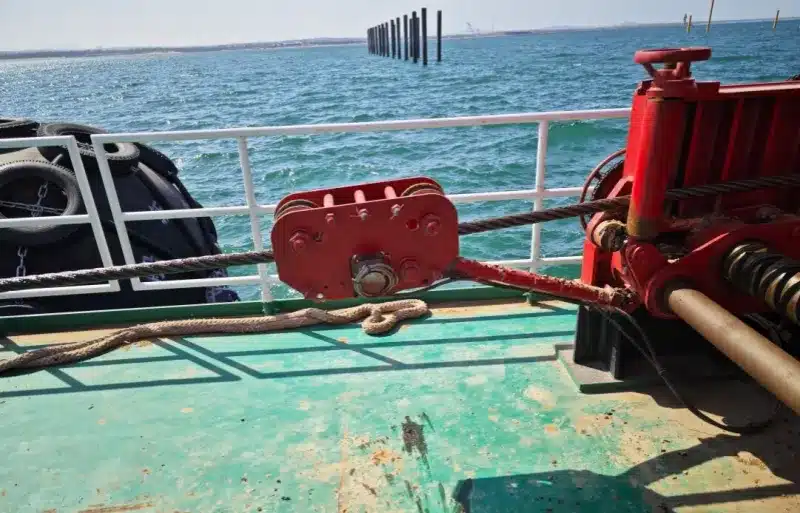

It is mainly used in large-scale engineering facilities that require anchoring, berthing or towing operations, including but not limited to: large engineering ships (such as dredgers, piling ships), floating cranes (heavy offshore hoisting equipment), oil tankers, bulk carriers and other large transport ships, barges (fixed moored water operations).Platform), anchorage (temporary berthing area for ships).

5. System composition

The monitoring system of WT-SHL type anchor rig and cable winch is composed of three parts: core perception components, data transmission components, and monitoring and early warning components. The components and functions are as follows:

Core perception components

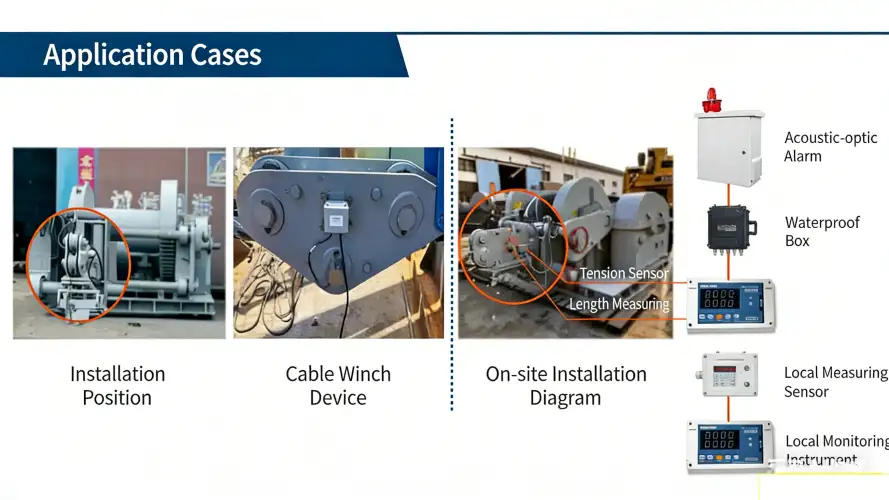

- Tension sensor: The core function is to collect cable traction and brake torque data, adapt to harsh operating environments such as offshore and humid, and ensure the stability and accuracy of data collection.;

- Length sensor: responsible for real-time measurement of the length of the cable retracted and released, and provides accurate length reference for anchoring and berthing operations.

Data transmission components

- Wireless signal transmitter /receiver: suitable for mobile operation scenarios such as engineering ships and floating cranes, it can realize wireless remote transmission of key data such as tension and length, and ensure real-time synchronization of data under mobile operating conditions.;

- Wired transmission module (industrial cable): Designed for fixed operation scenarios such as anchorages and barges, it has strong anti-interference capabilities to ensure stable data transmission without delay and meet the communication needs of centralized monitoring.

Monitoring and early warning components

- On-site monitoring instrument: equipped with a 7-inch high-definition display terminal, which can display cable tension and retractable length data in real time, support safety threshold setting and alarm information viewing, easy and intuitive operation;

- Sound and light alarm: When the system detects abnormal working conditions such as overload and over-torque, an obvious sound and light warning is immediately issued, and the warning range covers the operation site to ensure that the operator is aware of the risk in a timely manner.;

- Waterproof box: used to protect on-site monitoring instruments, sensor interfaces and other equipment, with good waterproof performance, suitable for offshore, humid and other multi-water environment operation needs, extend the service life of equipment;

- Monitoring center equipment (including special software): It can centrally display the operating data of multiple anchor machines/winches, such as the tension of anchor machine No. 1 and cable length of anchor machine No. 2. It supports data query, historical playback and report export functions to achieve unified control of multiple equipment.