Product introduction: Based on independently developed magnetic sensors and international standard magnetic memory flaw detection principles

In the industrial field, wire rope serves as a crucial load-bearing and traction component, widely applied in industries including ports, ships, roads and bridges, cableways, steel mills, hoisting, construction sites, and petroleum. It is the "lifeline" of numerous equipment.

However, for a long time, the maintenance and management of wire ropes in hoisting equipment have been a key challenge for enterprise equipment management. Wire rope breakage accidents occur frequently, each accompanied by severe property losses and casualties, imposing heavy costs on enterprises and society.

The traditional detection methods of "visual inspection, caliper measurement, and manual touch" are inefficient with high missed detection rates, making it difficult to meet the demands of digital management.

Based on independently developed magnetic sensors and international standard magnetic memory flaw detection principles, Microtest Technology has launched the WRNDT Wire Rope Non-Destructive Testing System.

Core equipment includes models such as WT-WRNDT-T and WT-WRNDT-HY, featuring "high efficiency, precision, convenience, and safety" as core characteristics.

1. Real-Time Monitoring of Full-Dimensional Damage

Based on a high-speed magnetic field vector detection array, it real-time collects data on internal and external damages such askinks, bends, lantern shapes, wear, broken wires,and corrosion.

Supports diameters from Φ10mm to Φ50mm(customizable for over-range sizes), enabling detection without affecting production and capturing millimeter-level micro-defects.

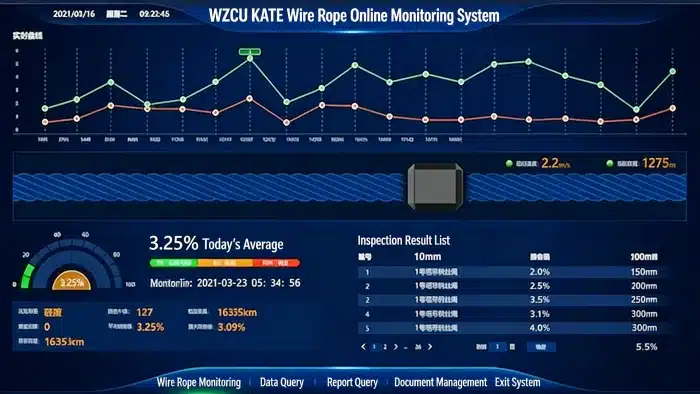

2. Intelligent Analysis and Visual Management

Integrates technologies such as wavelet algorithms and neural networks to automatically identify the degree and location of damage.

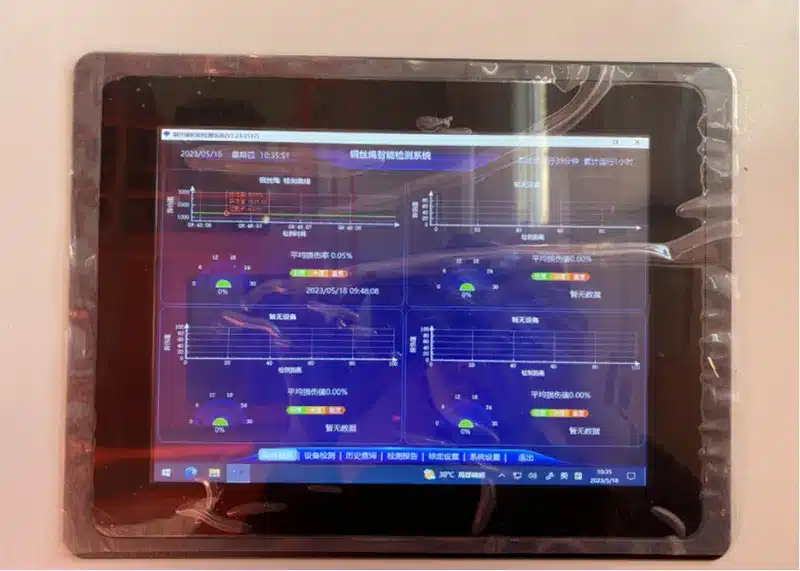

Generatesvisual reportsincluding electromagnetic waveforms and damage point positioning. The supporting software supports real-time monitoring, historical traceability, and multi-level alarms.

Visual system interface

Detection Report

3. Remote Interconnection and Predictive Maintenance

Supports Ethernet and wireless transmission, seamlessly accessing remote monitoring platforms and synchronizing data in real-time.

Early warning of potential defects through internal stress trend analysis, transforming "post-failure maintenance" into "preventive maintenance" and extending the service life of wire ropes.

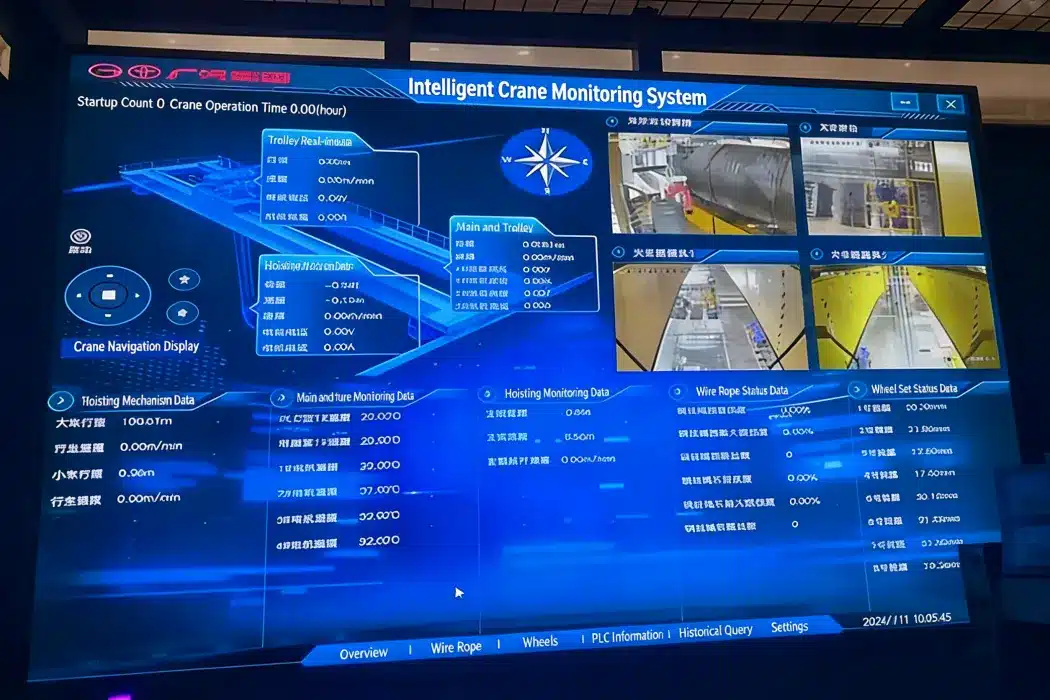

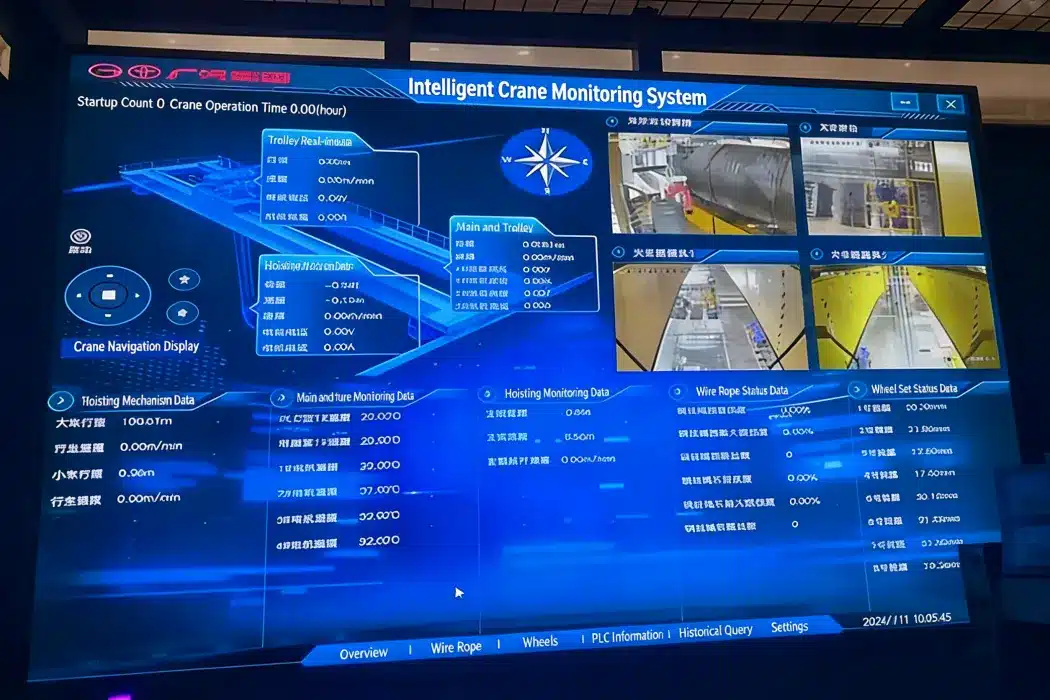

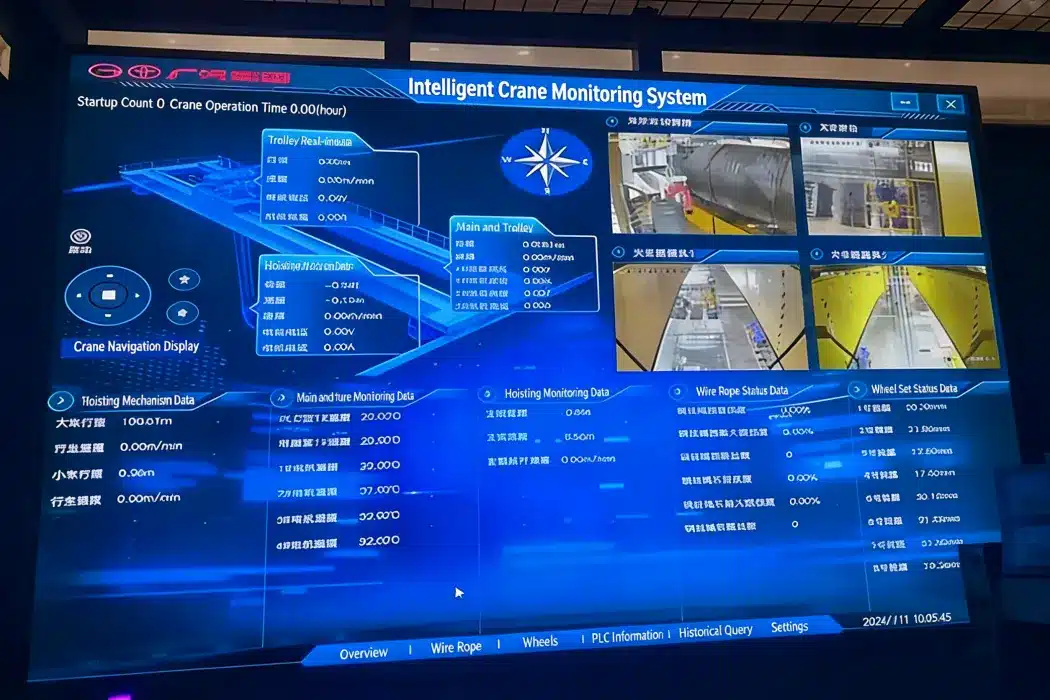

Access to the Comprehensive Management Platform of a Certain Automobile Enterprise

1. Online Type

Application Scenarios:Suitable for 24/7 continuous monitoring scenarios such as port cranes, gantry cranes, and tower cranes.Sensors can be fixed on wire ropes.

Core advantages:Real-time detection, automatic alarm, cloud data storage, support for remote report export, and adaptation to clustered management.

2. Integrated Type

Application Scenarios:Multi-equipment safety management systems in smart factories and large-scale infrastructure projects.

Core advantages: Multi-parameter interfaces, compatible with other management systems, and meeting personalized monitoring needs.

3. Portable Type

Application Scenarios:Mobile testing scenarios such as road and bridge inspection and temporary hoisting.

Core advantages: Lightweight design, built-in lithium battery with sensorbattery life of over 6 hours,ready-to-use, and rapid report generation.

4. Maintenance Type

Application Scenarios:Scenarios with high regular maintenance requirements such as port machinery and cableway equipment.

Core advantages: Integratingcleaning, testing, and oiling functions,completing the entire process with one click and replacing manual operations.

1. Core Mechanism of Magnetic Memory Flaw Detection

Based on magnetic field radiation theory, it monitors changes in the stray magnetic field vector detection array.

No additional magnetization device is required. Through independently developed high-sensitivity magnetic sensors, it identifies early fatigue damage and hidden cracks.

2. Multi-Technology Integrated Detection System

Multi-data fusion technologies such as wavelet algorithms and neural networks are used to ultimately identify the damage degree and location of wire rope damage points, accurately distinguish damage types, and quantitatively evaluate results.

1. Preprocessing-Free, Minimal Operation and Maintenance: Sensors are waterproof and dustproof. No need to clean the wire rope surface, and no disassembly or shutdown is required before testing.

2. High-Precision Detection, No Hidden Dangers:The error of broken wires per lay length can beless than 2 wires, and the accuracy ofdamage point positioning is over 95%..

3. Full-Lifecycle Health Management, Predictive Maintenance:It can detect existing defects and predict potential future damage risks based on changes in internal stress. It assists in formulating scientific replacement cycles and avoiding cost waste.

4. Full-Scenario Adaptation, Flexible Deployment:Covering mainstream wire rope specifications, it provides multi-form equipment to adapt to complex industrial scenarios. It supports various deployment methods such as fixed installation and temporary erection to meet differentiated needs.

1. Major Infrastructure: Guanyinsi Yangtze River Bridge on Wusong Expressway

The system is installed on Zoomlion R4300-200 tower cranes, providing 24/7 real-time monitoring and early warning of early wear and broken wire risks.

Following Changtai Yangtze River Bridge and Ma'anshan Highway-Railway Yangtze River Bridge, it has become the preferred solution for another super project.

2. Automobile Manufacturing: Three Major Automakers - Dongfeng, GAC, and Changan

Integrated equipment is connected to the factory MES system to achieve real-time synchronization of detection data and management platforms.

It helps build "zero wire rope breakage" smart workshops and has been rated as a typical case of digital transformation in the industry.

3. Energy Sector: Wudongde Hydropower Station

Portable equipment quickly identifies internal broken wire hazards in high-humidity environments.

Wtau technological innovation, Microtest Wire Rope Non-Destructive Testing System strengthens the industrial safety line. From equipment detection to platform interconnection, it promotes wire rope management into a new era of precise, scientific, and data-driven decision-making.

Previous article:

Next Article:Wtau WTYJ-YJQ Type Crane Anti-Electric Shock Early Warning System »