1. Product introduction

Industrial wireless remote controls are remote control systems specially designed for lifting machinery, engineering vehicles and heavy industrial equipment. Through advanced wireless communication technology and safety protection mechanisms, precise remote control of large machinery such as hydraulic cranes, cranes, excavators, and port handling equipment is achieved, significantly enhancing operational safety and efficiency.

2. Industry Pain Points

- High security riskOperators need to operate at close range and are exposed to safety threats such as falling objects from heights and equipment collisions

- The operating field of vision is limited.There is a blind spot in the cab's viewing Angle, which affects the operational accuracy and work safety

- The labor cost is high.Traditional operations require the cooperation of multiple people, and labor costs continue to rise

- Low work efficiencyThe operation is not flexible, the equipment utilization rate is low, and it affects the overall operation efficiency

- The working environment is harsh.Operators have been exposed to adverse environments such as noise and dust for a long time

- Insufficient emergency responseThere is a lack of a rapid safety protection mechanism in emergency situations

3. Solutions

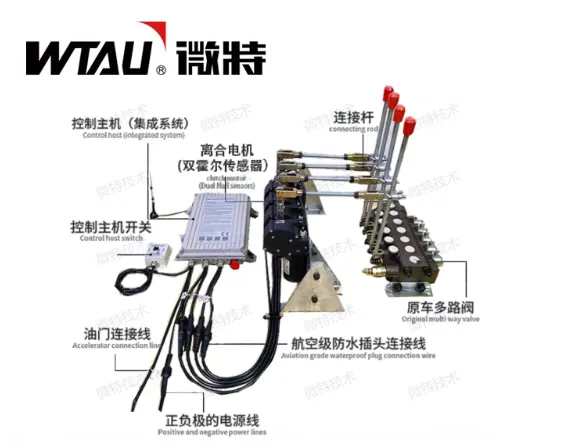

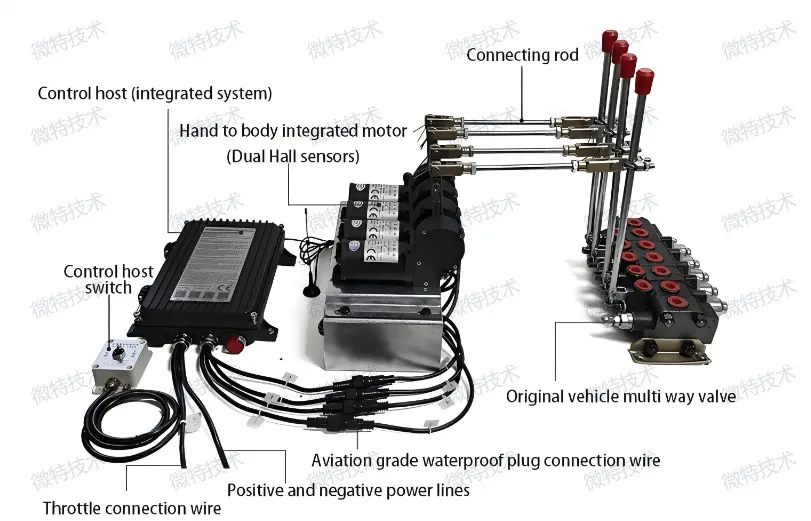

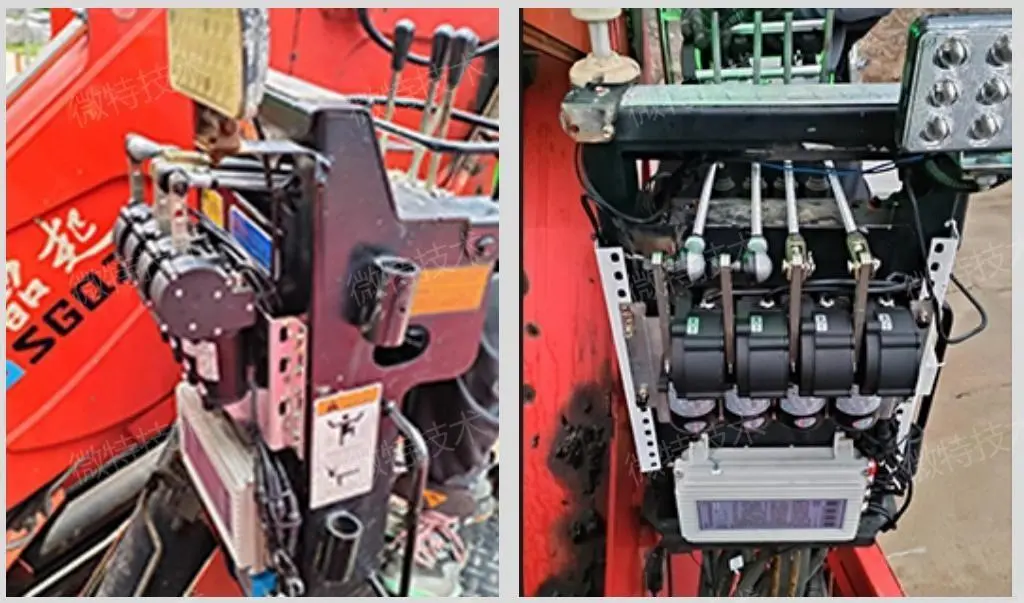

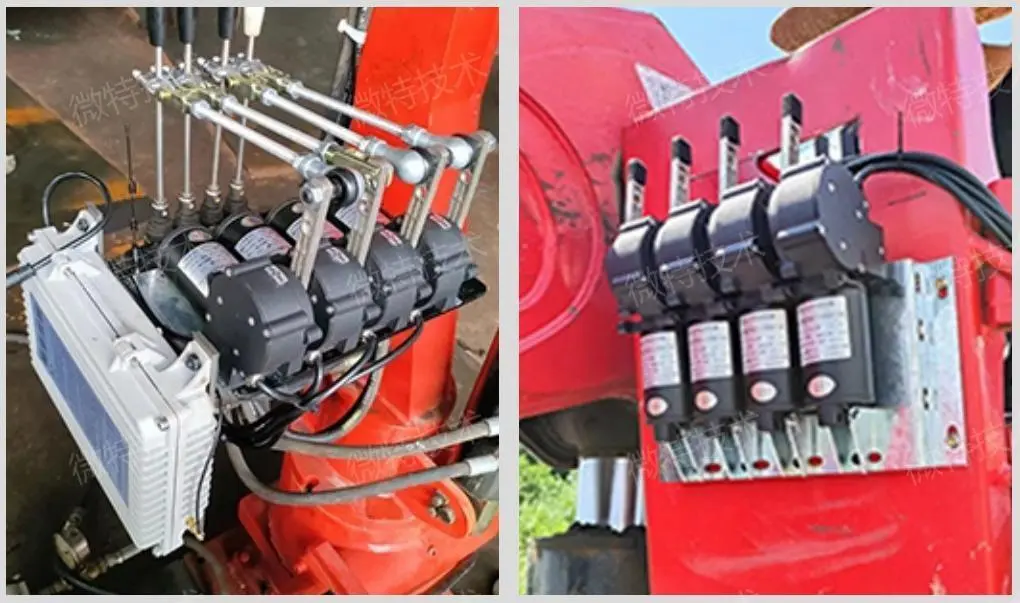

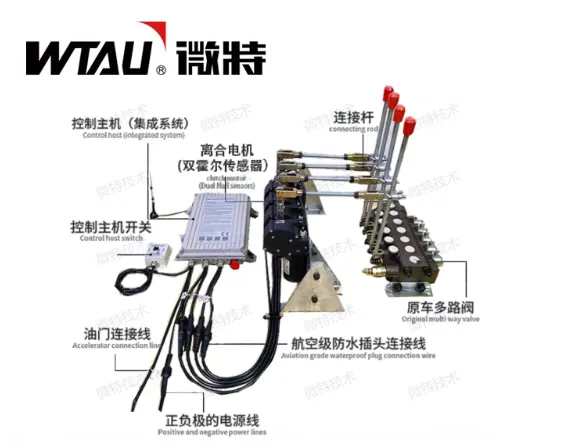

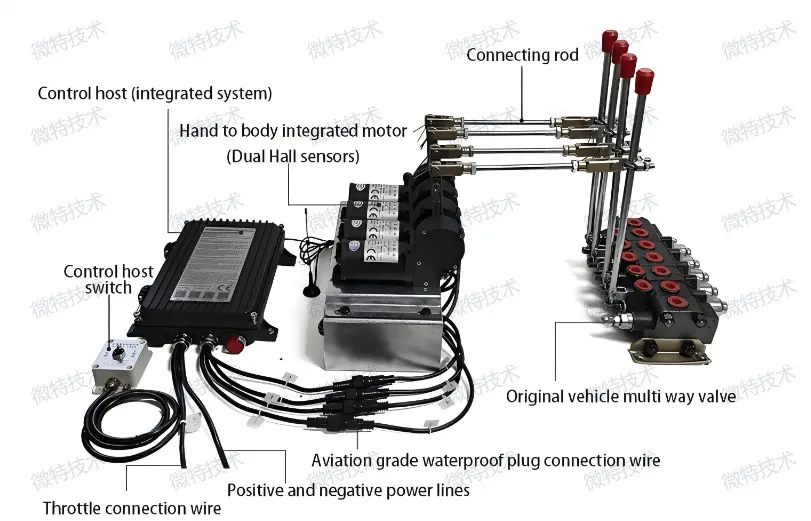

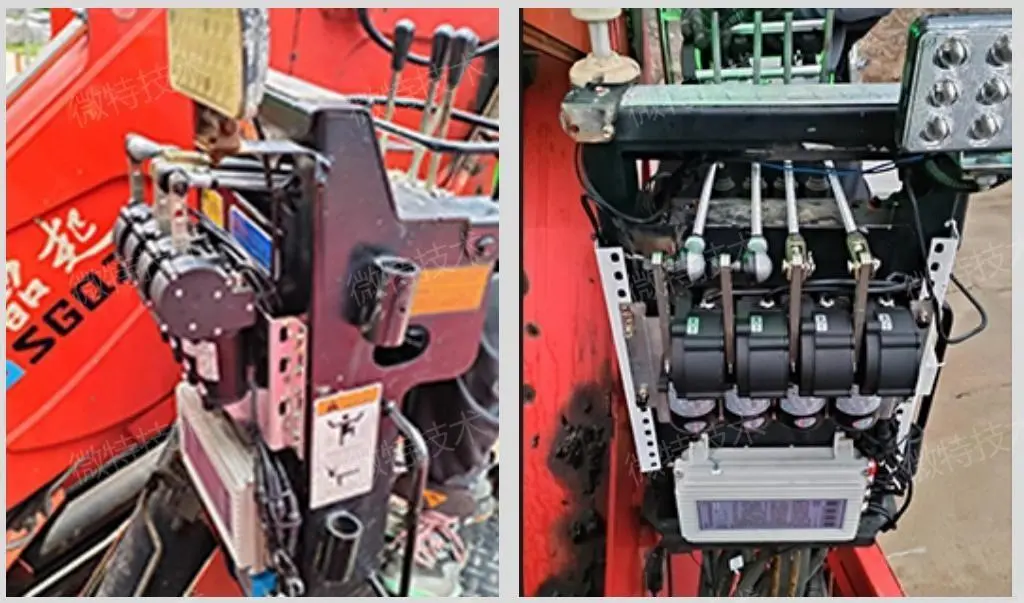

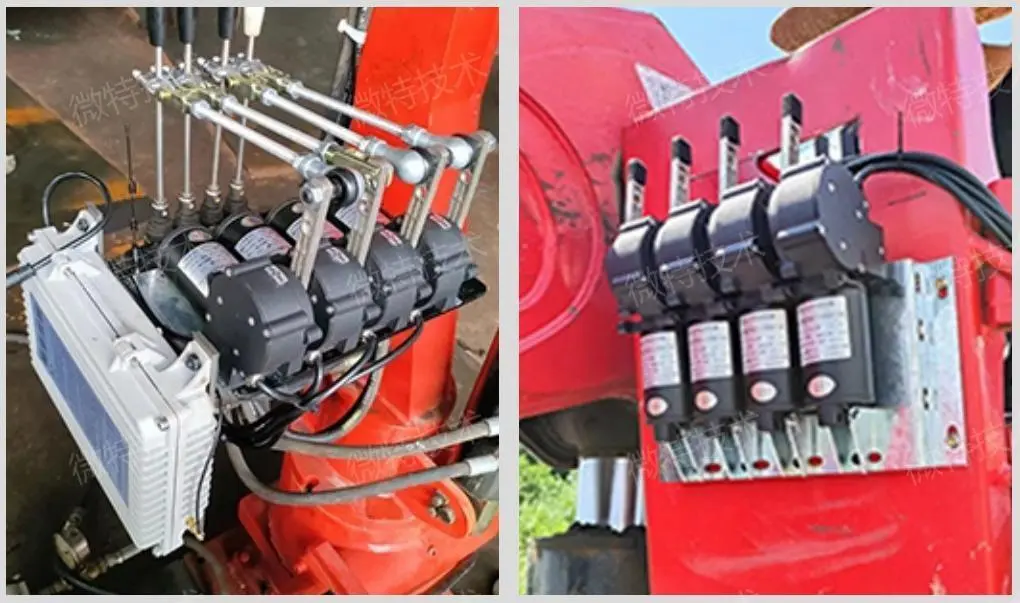

Adopt a three-step simple modification plan to quickly achieve the wireless remote control transformation of the equipment:

- Install the receiving moduleEquipped with high-power transceiver devices to ensure stable signal transmission

- Connection control systemIt adopts a waterproof plug for independent connection, which is convenient for maintenance and replacement

- Debug the safety systemMultiple safety protection mechanisms are set up to ensure safe and reliable operation

After modification, it can achieve unobstructed remote control within 50 to 500 meters, allowing operators to perform precise control from the best perspective.

4. Main Functions

- Remote precise controlRealize wireless remote control of all functions of lifting machinery

- Multiple safety protectionsEmergency stop button, lock function, automatic protection against power failure and signal interruption

- Intelligent status monitoringReal-time monitoring of battery power, signal strength and device status

- Waterproof and dustproof designWith an IP67 protection rating, it is suitable for various harsh working conditions

- Quick installation and modificationModular design, supporting rapid transformation and upgrading of existing equipment

- Adaptive matchingCustomized configuration can be carried out according to the characteristics of different devices

5. Core Advantages

- Safe and reliableIt adopts imported Hall sensors, which feature good stability, high accuracy and long service life

- Convenient operationIt can be put into use in just three steps and supports quick locking and unlocking functions

- Waterproof and durableOne-piece molded waterproof plug, still working normally when immersed in water

- Easy to maintainModular design allows each component to be independently inspected and replaced

- Cost-effectivenessSingle-person operation replaces multi-person collaboration, significantly reducing labor costs

- Emergency protectionIt automatically resets in emergency situations to ensure the safe shutdown of the equipment

6. Application Cases

Remote control transformation of port cranes

Renovation of the electrical control system for cranes at a large port container terminal

- Equipment renovation: 32-ton port crane

- Control distance: 200 meters for unobstructed operation

- Results: The number of operators decreased by 50%, and the operation efficiency increased by 35%

Remote control system for overhead cranes in steel structure factory buildings

Wireless remote control renovation project for Overhead Cranes in Manufacturing Enterprise Factory buildings

- Equipment renovation: 10-ton bridge crane

- Features: Achieve precise hoisting and eliminate blind spots in operation

- Achievements: The safety accident rate decreased by 90%, and production efficiency increased by 40%

Remote control system for mining excavators

Wireless remote control transformation of Large excavators in mining areas

- Equipment renovation: 45-ton hydraulic excavator

- Environment: High dust and high-intensity working conditions

- Results: Operators are kept away from dangerous areas, and the equipment utilization rate has increased by 301T to 3T

Applicable equipmentHydraulic cranes, bridge cranes, gantry cranes, excavators, loaders, port handling equipment, mining machinery, etc