I. Product Overview

The WS-W660 series automatic lubrication system for crane and transfer equipment is a professional solution developed by WTAU Technology specifically for the lubrication needs of industrial equipment. It covers multiple types of products including progressive, single-line, dual-line, intelligent lubrication, and open gear spray lubrication systems, adapting to centralized or independent automatic lubrication scenarios of small, medium, and large-sized equipment.

Integrating core technologies such as precise metering, intelligent control, and remote monitoring, the system completely replaces the traditional manual lubrication mode to achieve automatic, timed, and quantitative delivery of lubricants. It effectively solves the pain points of industrial equipment such as uneven lubrication, cumbersome maintenance, and frequent failures. The product is widely used in industries such as marine engineering, energy, ports, metallurgy, chemical industry, coal mining, cement, and power plants, and is suitable for various crane, transfer, and heavy-duty equipment such as cranes, ball mills, rotary kilns, and dryers. It also supports customized R&D and design to meet personalized lubrication needs under different working conditions.

II. Core Functions

1. Automatic Precise Lubrication to Ensure Long-Term Equipment Operation

The system adopts timing control or counting control mode. In timing mode, the lubrication time and interval time can be flexibly adjusted; in counting mode, the number of lubrication cycles and interval time can be set as needed to achieve continuous and stable automatic lubrication. Through precise metering devices, a set dose of lubricant (suitable for most greases of NLGI 2# and below) is delivered to each lubrication point to form a uniform oil film, reduce equipment wear, and extend service life.

2. Full-Process Status Monitoring and Rapid Fault Location

It integrates system control and monitoring units to real-time monitor the pressure, flow, remaining grease volume, and valve group action status of the lubrication system. Some high-end models (such as intelligent lubrication systems) can realize independent monitoring of the working status of each lubrication point. When problems such as blockage of lubrication points, insufficient grease, or abnormal pressure occur, the system promptly feeds back alarm information and quickly locates the fault point to avoid equipment shutdown caused by lubrication failure.

3. Strong Adaptability and Flexible Scene Expansion

The product can operate stably in a wide temperature range, long distance (up to 120 meters), and harsh working conditions (high temperature, high dust, humidity, etc.). Some models support a single system serving up to 2000 lubrication points. The system adopts a modular design, facilitating installation, adjustment, and maintenance. The scale of the system can be easily expanded or reduced by adding or removing metering devices without redesigning the overall structure, adapting to equipment upgrades and changes in working conditions.

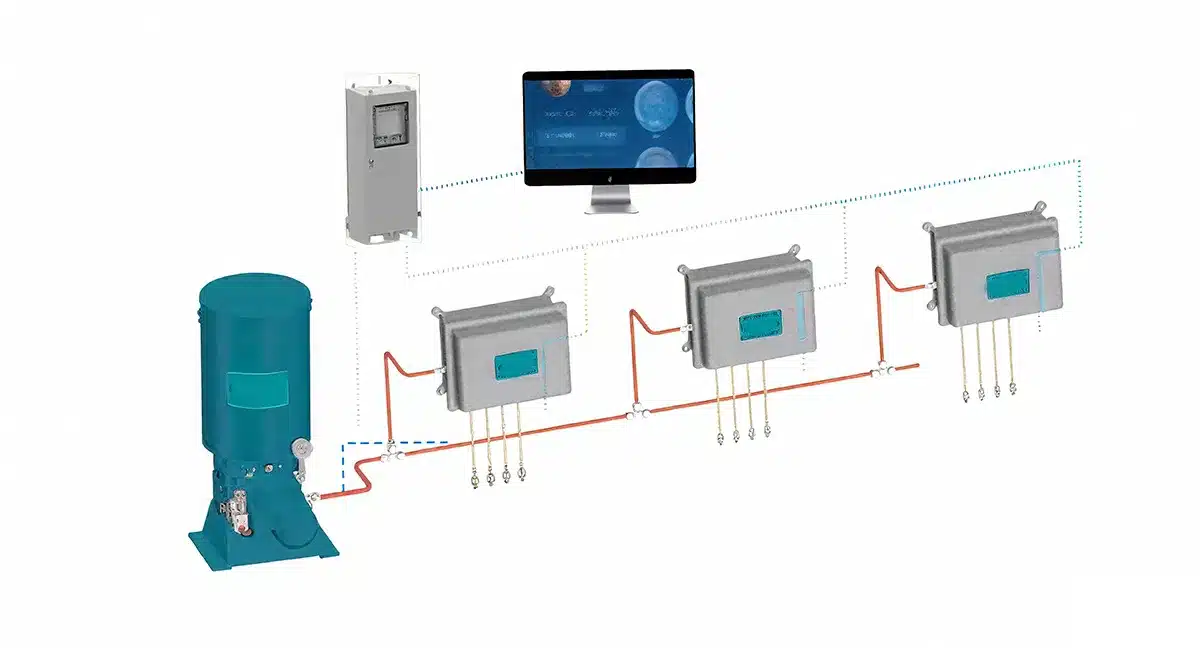

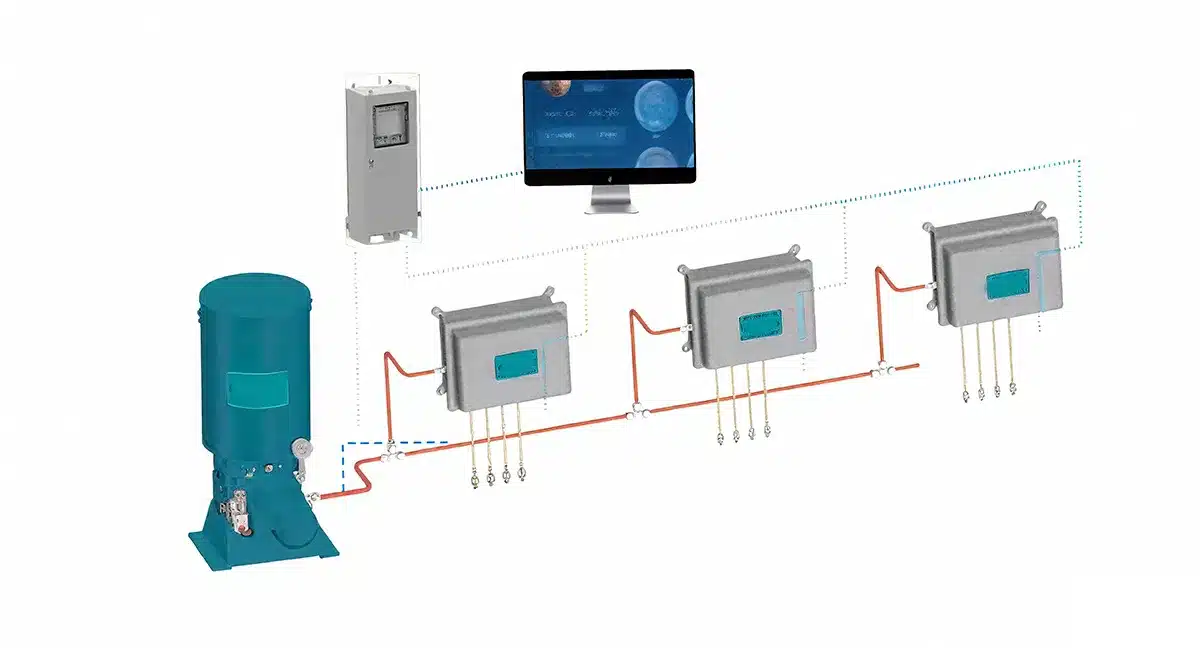

4. Intelligent Visual Management to Improve Operation and Maintenance Efficiency

Intelligent products support linkage between upper computers and control centers to realize visual monitoring and operation. Staff can control the operation status of all lubrication systems in the control center. At the same time, it has the functions of lubrication volume statistics and summary, and report generation, providing data support for equipment operation and maintenance, and reducing labor costs and management difficulties.

III. Product Selection

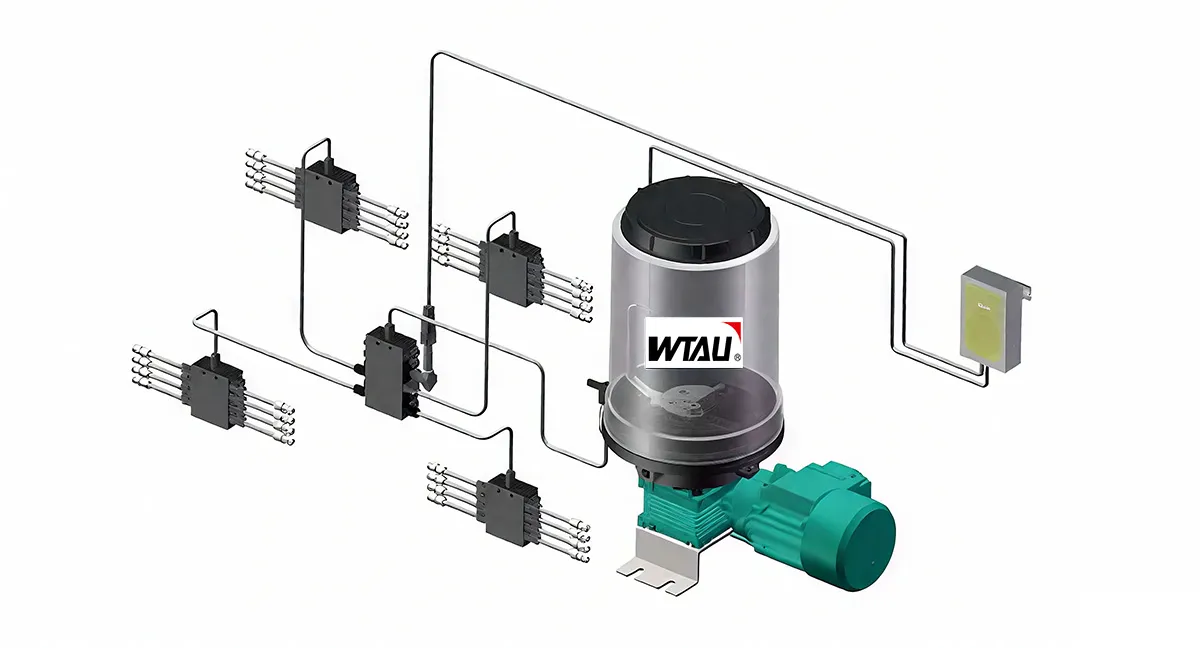

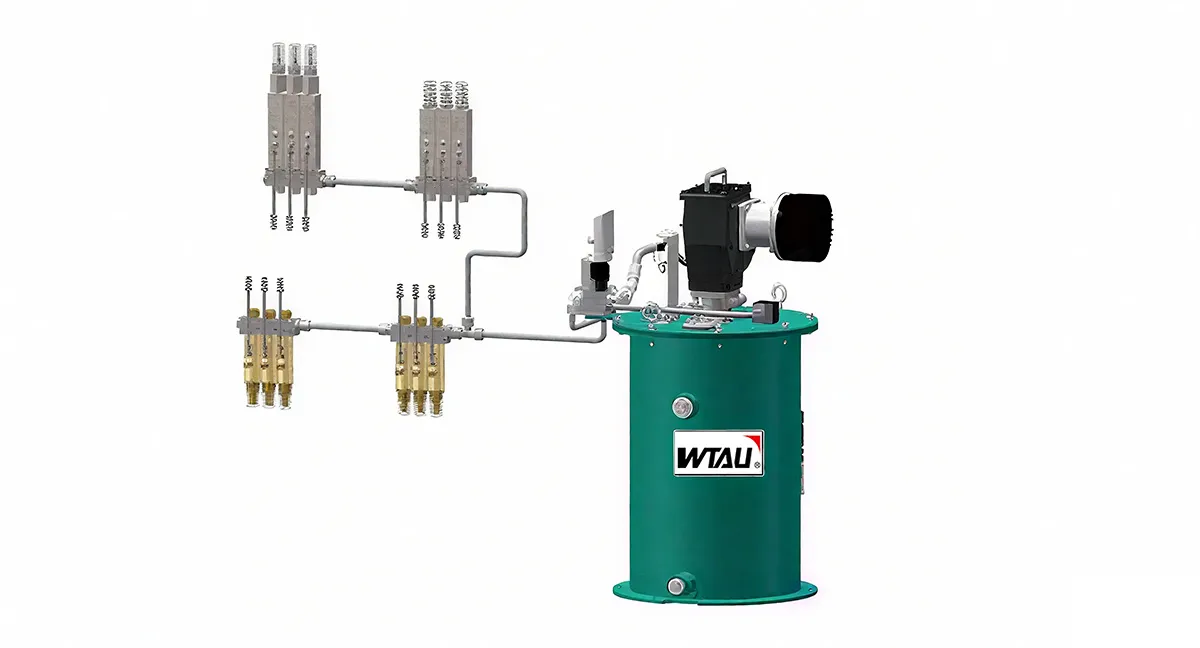

1. WS-W660V2 Progressive Lubrication System

- Application Scenarios:Centralized lubrication operations for small and medium-sized equipment requiring continuous lubrication (such as small cranes and light conveying equipment).

- Core Features:Compact structure, integrated control and monitoring functions, stable high-pressure pumping performance, high efficiency in short-distance lubrication, convenient installation and maintenance, suitable for most greases of NLGI 2# and below.

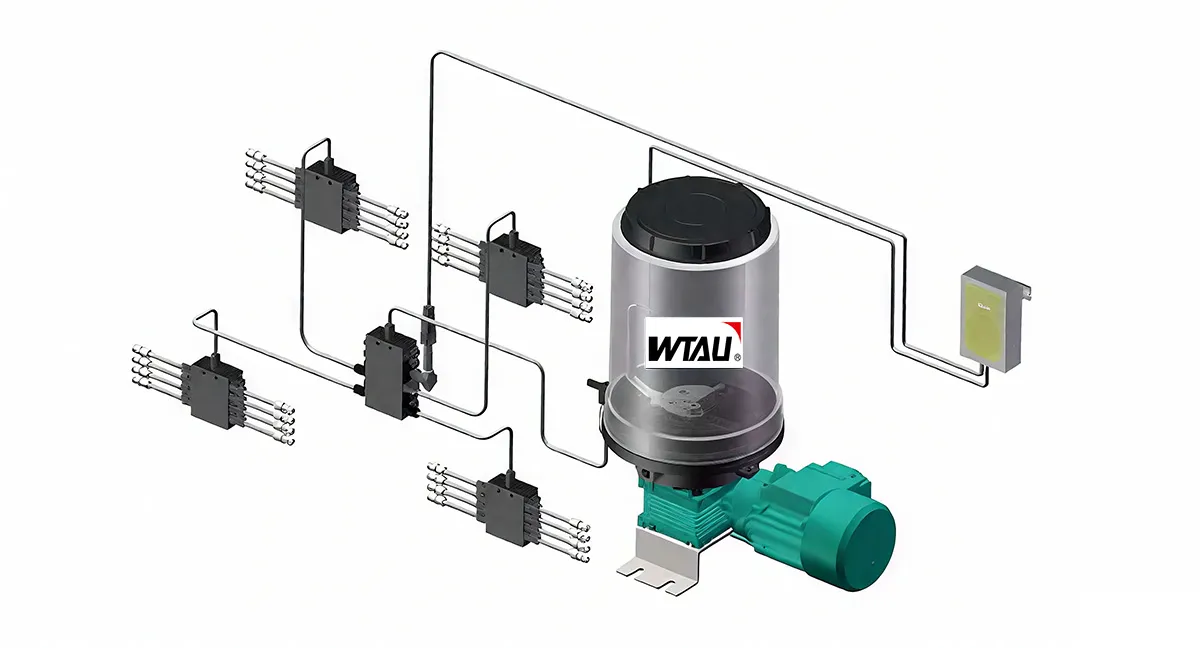

2. WS-W660V3 Single-Line Lubrication System

- Application Scenarios:Centralized lubrication operations for medium-sized equipment requiring continuous lubrication (such as medium-sized cranes and general machinery).

- Core Features:Single main oil circuit design, each distribution unit corresponds to one lubrication point, and the displacement can be adjusted (some support fixed displacement selection); blockage of a single lubrication point will not affect the operation of the entire system, strong expandability, long-distance pumping, suitable for equipment with complex layouts.

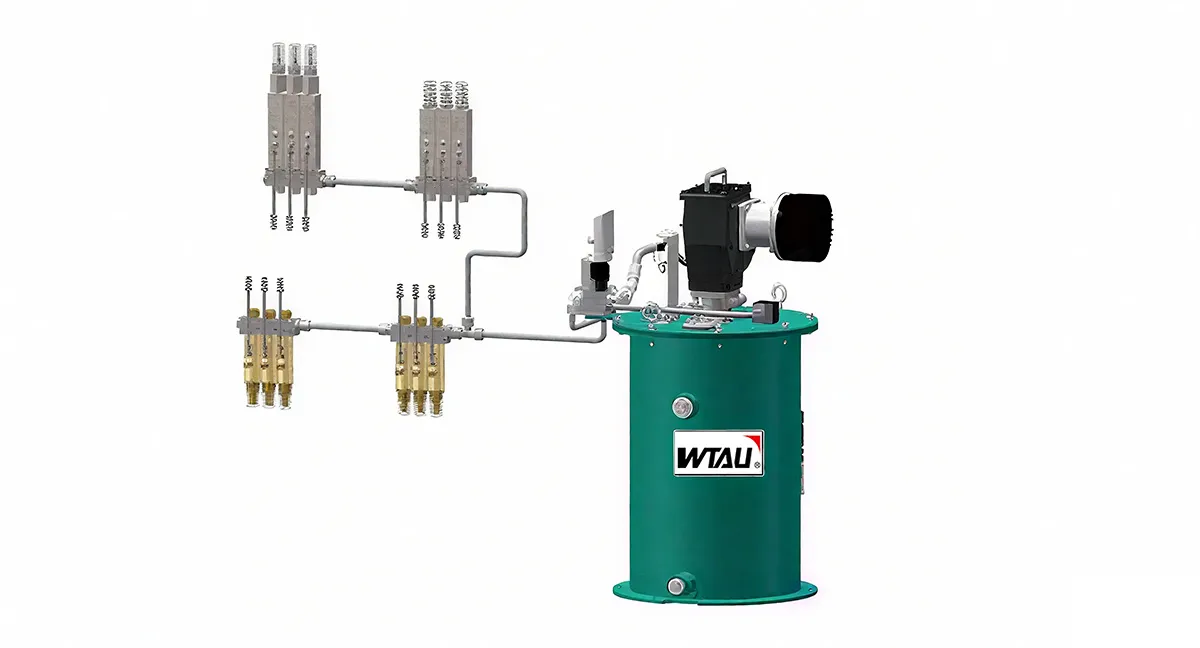

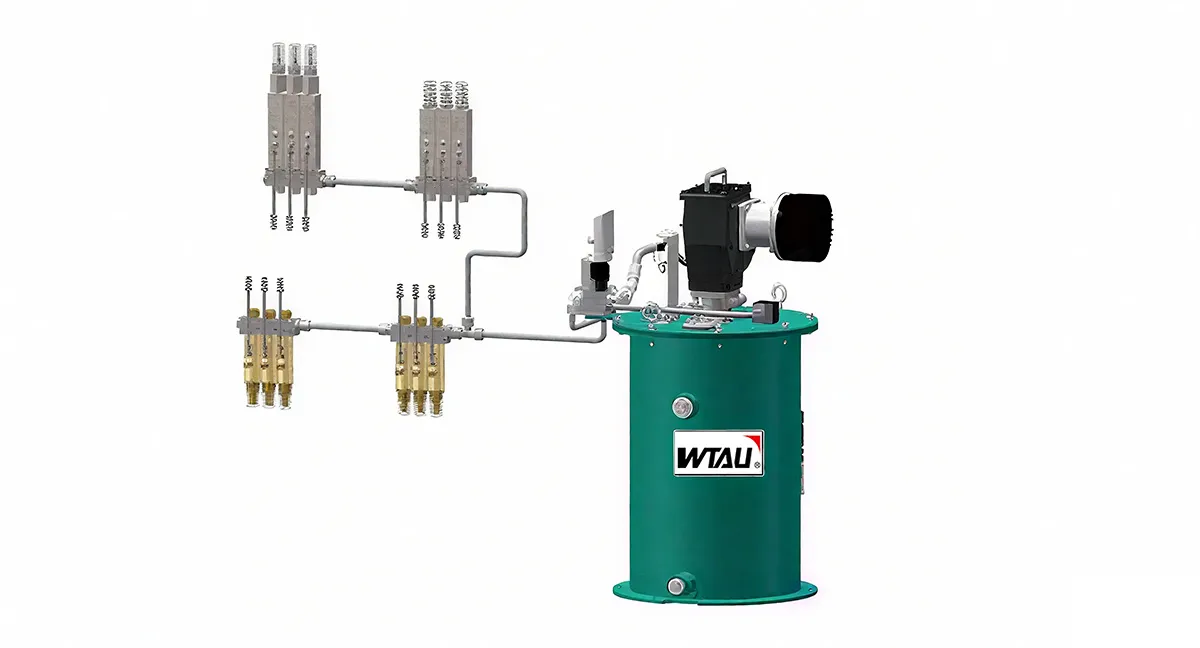

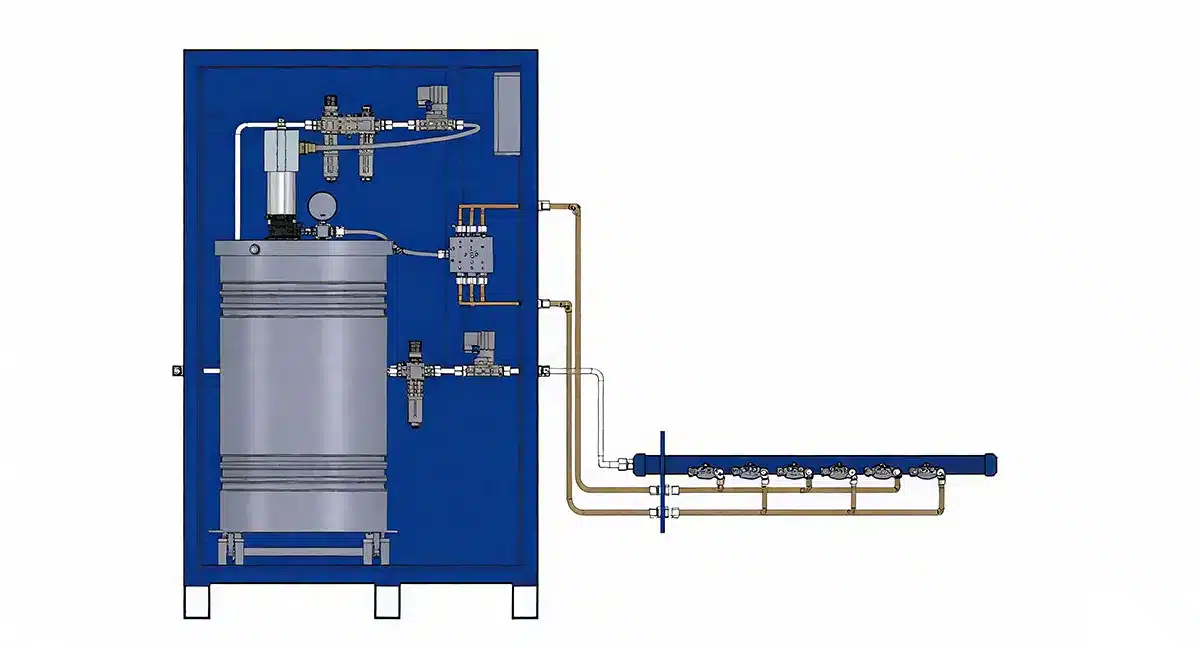

3. WS-W660V4 Dual-Line Lubrication System

- Application Scenarios:Lubrication of decentralized lubrication points of large equipment (such as large cranes and mining machinery), and multi-lubrication point scenarios requiring different lubrication amounts.

- Core Features:Dual main lines supply oil alternately, working pressure up to 400bar, maximum delivery distance of 120 meters, supporting up to 2000 lubrication points; can be combined with progressive metering devices to expand the number of lubrication points, flexible installation and adjustment, adapting to the lubrication needs of large and complex equipment.

4. WS-W660V5 Intelligent Lubrication System

- Application Scenarios:Lubrication of decentralized lubrication points of large equipment (such as large cranes and mining machinery), and multi-lubrication point scenarios requiring different lubrication amounts.

- Core Features:Dual main lines supply oil alternately, working pressure up to 400bar, maximum delivery distance of 120 meters, supporting up to 2000 lubrication points; can be combined with progressive metering devices to expand the number of lubrication points, flexible installation and adjustment, adapting to the lubrication needs of large and complex equipment.

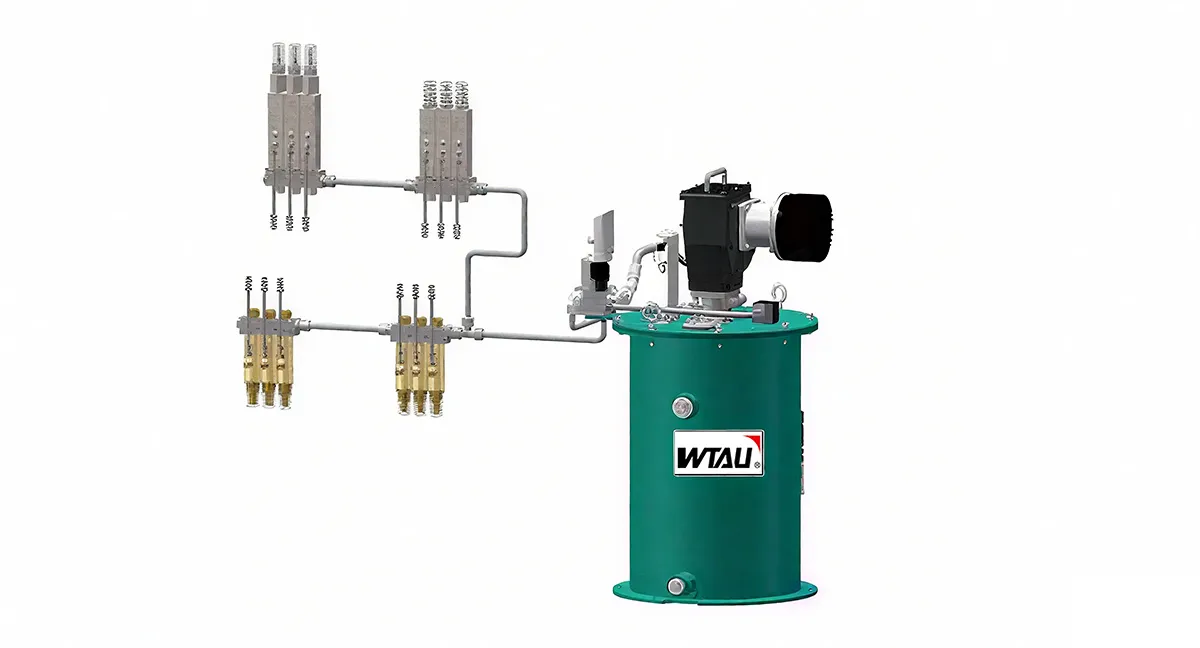

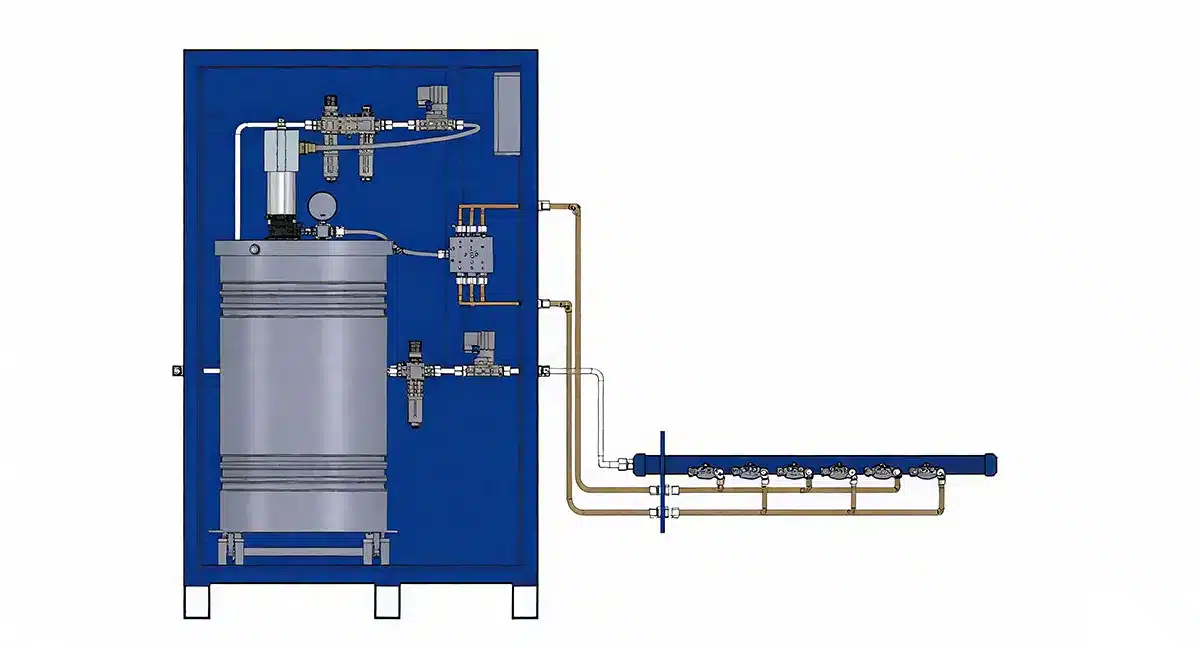

5. WS-W660V6 Open Gear Spray Lubrication System

- Application Scenarios:Lubrication and cooling of large heavy-duty open gear pairs of equipment in industries such as power plants, mining, cement, and metallurgy (such as ball mills, rotary kilns, and dryers).

- Core Features:Gear lubrication width covers 50mm-1060mm, periodic oil injection forms a durable oil film; supports multiple lubrication cycle settings, with fault monitoring function and nozzle "post-blow" function, and can work stably in various weather and environmental conditions.

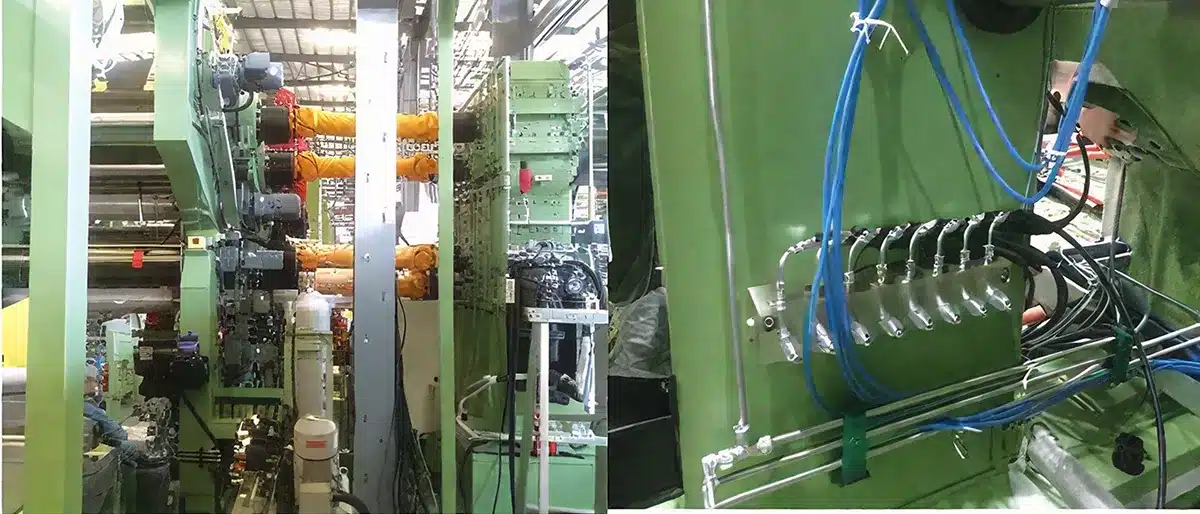

IV. Installation Diagram

The WS-W660 series automatic lubrication system adopts a modular design with a standardized installation process and clear layout of core components. The following is the general installation logic and precautions (the specific installation plan can be adjusted according to the equipment type, working conditions, and customized requirements):

1. Layout of Core Components

- Supply Unit(lubricating pump, grease storage tank): Installed in an area of the equipment that is easy to maintain and away from high temperature and high pressure, ensuring convenient grease supply and firm fixation of the pump body to avoid vibration impact.

- Distribution Unit(progressive/single-line/dual-line distributor): Arranged near the centralized area of lubrication points to reduce pipeline length and improve oil supply efficiency; the distributor is installed horizontally to ensure smooth movement of internal valve cores.

- Control and Monitoring Unit(main control cabinet, pressure/flow sensor): Installed in the operation room or equipment control cabinet in a ventilated and dry environment, facilitating staff to check the status and debug parameters.

- Pipeline Accessories: Use high-pressure wear-resistant oil pipes, reasonably plan the pipeline route according to the equipment layout to avoid bending and pressure, install fixed buckles at key nodes, and ensure tight sealing of oil pipe interfaces to prevent leakage.

2. Core Installation Precautions

- The pipeline layout should follow the principle of "short path and fewer bends". For long-distance transportation, set supporting points reasonably to ensure stable oil supply pressure.

- Precisely connect the lubrication point interface with the oil outlet of the distributor, adjust the oil output according to the needs of the lubrication point, and verify the oil supply status of each lubrication point one by one during commissioning.

- The wiring connection between the control unit, supply unit, and distribution unit should be standardized with reliable grounding to avoid electromagnetic interference affecting system operation.

- After installation, conduct pressure testing, leakage detection, and lubrication cycle debugging to ensure the system meets the equipment lubrication requirements.