The WSTA-HDVS(800) Y-type workstation video surveillance system is a high-definition video surveillance system specially designed for the safe operation of metallurgical cranes in steel mills. It is dedicated to addressing major safety hazards caused by incomplete hooking and incomplete unhooking during the hoisting process of iron and steel ladles. This system achieves real-time and blind-spot-free monitoring of key linkage processes through multi-station video synchronous monitoring and remote centralized control management, significantly enhancing operational safety and production efficiency.

System core functions

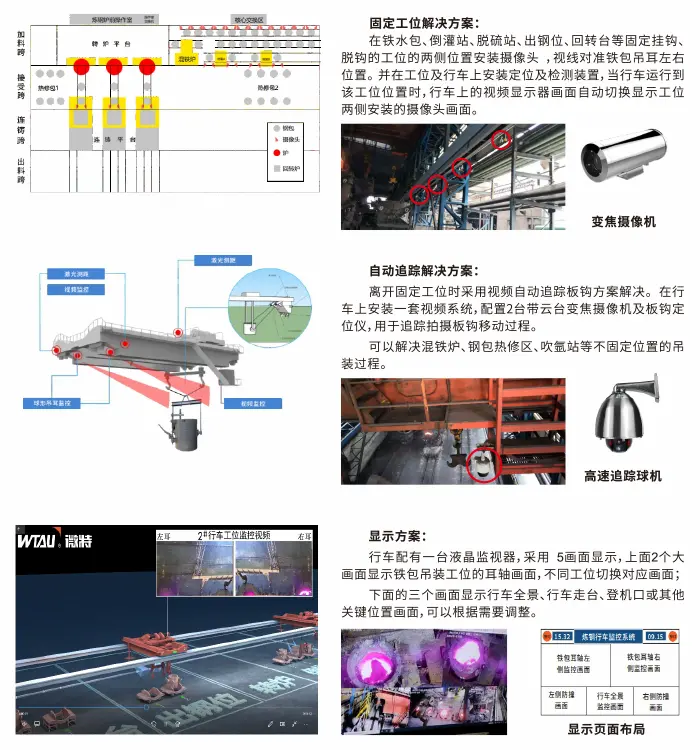

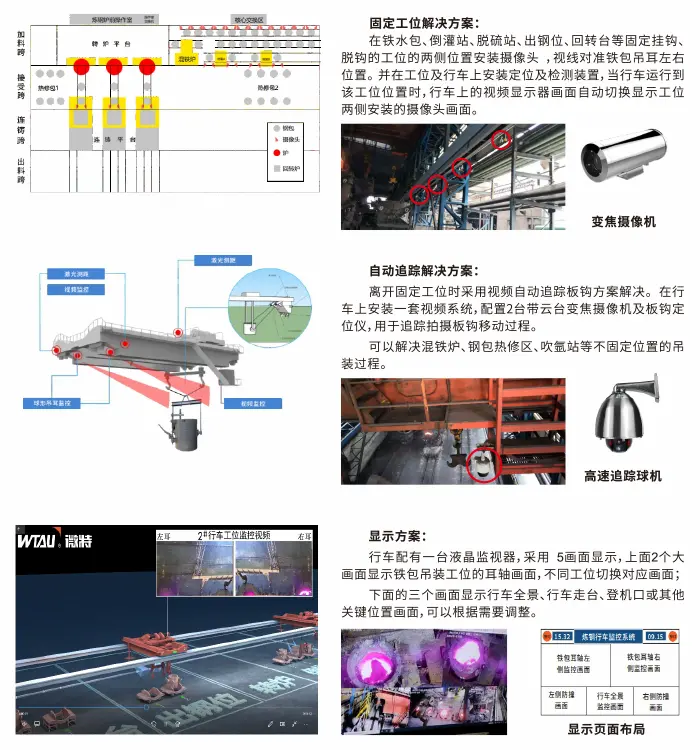

- Real-time synchronous monitoring of the three locationsHigh-definition camera equipment and displays are respectively deployed in the fixed ground workstations, crane operation rooms, finger lifting rooms and main control rooms to achieve real-time and synchronous viewing of the entire process of hooking and unhooking from multiple perspectives and locations.

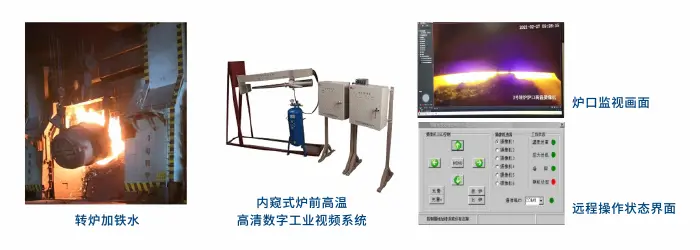

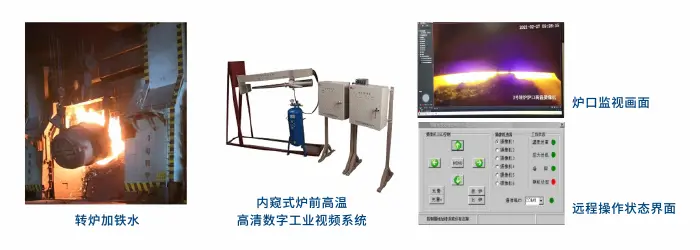

- Adaptability to high temperature and strong lightThe system is equipped with a super strong light suppression function and high-tolerance optical components, ensuring clear and stable images even in harsh industrial environments such as high temperatures, dust, and strong light.

- Video storage and retrospectionSupports full-station video recording and cloud/local storage. Historical images can be retrieved based on multi-dimensional conditions such as time, device, and IP, providing data support for accident traceability and operation optimization.

- High-reliability designIt adopts sapphire lenses, vortex coolers and a three-stage air cooling system. The lens part can withstand a high temperature of 2000℃. The pneumatic advance and retreat mechanism can automatically exit the high-temperature zone in case of power failure or other unexpected situations, ensuring the safety of the equipment.

Technical features

- High-definition and low-latency transmissionRelying on a high-speed industrial wireless local area network, it realizes the synchronous transmission and display of video signals among the crane, the crane room and the main control room, with low picture latency and prompt operation response.

- Centralized control and displayIt supports the centralized display of video images of key points in the main control room through video walls and splicing screens, and has multi-screen splitting, round-robin, grouping and playback functions, which is convenient for global monitoring and dispatching.

- System compatibility and expansionIt can be seamlessly integrated into the entire factory's information management platform and operate in coordination with systems such as crane weighing, anti-collision, and fatigue monitoring to build an intelligent safety management ecosystem for metallurgical lifting equipment.

Application value

The WSTA-HDVS(800)Y system has been widely applied in the metallurgical hoisting operation scenarios of major steel mills, significantly reducing the risk of ladle overturning caused by blind spots, command errors, and improper hooking. After the system was put into use, the management and production efficiency increased by more than 15%, and the rate of safety accidents dropped significantly. It provided key visual technology support for achieving "unmanned, intelligent and remote" hoisting operations in the metallurgical industry.