1. Product Introduction

WTL-A100N torque limiterIt is the basis of micro and special technologyNational standards GB12602-2009 and GB6067.1-2010The new generation of crane safety protection devices developed. It is specially designed for cranes that need to frequently adjust their working conditions. By monitoring key parameters such as weight and Angle in real time, it dynamically calculates the actual moment value. When the load approaches the critical state, the system automatically triggers an audible and visual alarm and cuts off dangerous operations, effectively preventing overloading accidents. Its integrated shockproof structure and high anti-interference feature make it particularly suitable for harsh outdoor working conditions.

2. Main functions

Triple safety protection and intelligent control

- Four-channel signal acquisition

Simultaneously connect four signals including the weight sensor (mV signal), Angle encoder (0-5V), and amplitude sensor (4-20mA)

Support mixed monitoring of hydraulic and mechanical cranes

- Dynamic torque calculation

The ARM processor performs 100 real-time operations per second

→ Load warning → Red light alarm → Forced power-off

- Self-healing mechanism for faults

The "Watchdog" circuit automatically resets and freezes (without manual intervention)

- Data transparent transmission expansion

The RS485 interface is directly connected to the PLC or remote monitoring platform

3. Typical applications

A model of safety protection for truck cranes

- Scene pain points:

Frequent amplitude variation operations at outdoor construction sites make traditional mechanical limiters prone to failure due to jolts

- Solution:

→ Weight monitoringMain hook wire rope tension sensor (the silver module on the right side of Figure 3)

→ Angle monitoringBoom root inclinometer (yellow equipment in Figure 3)

→ Interlocking controlWhen the main unit of the cab is overloaded, the winch will automatically lock

- User value:

After the installation of a 25-ton truck crane in a certain logistics company, the rate of misoperation due to overloading has dropped significantly

4. Core advantages

Ten years of verified engineering-grade reliability

- Hardware

Industrial wide-temperature chip (-30℃ to 70℃), three-level lightning protection circuit, 15KV static protection

- Zero learning cost operation

3-key control: Set/Confirm/Switch; fault code voice broadcast

- Lifetime maintenance-free design

The fully sealed metal casing is dust-proof and water-proof. The circuit board is coated with a three-proof coating

- Five-minute transfer and installation

Aviation plug quick-release structure: No need for recalibration

5. Technical parameters

- Signal processing4 analog input channels (mV/mA/0-5V)

- Precision gradeSystematic error ≤±5% (national standard requirement ≤±8%)

- Environmental Resistance:Temperature: -30℃ to 70℃; Humidity: 951 ° T - 3T; No condensation

- Electrical Characteristics::

Power supply: DC24V (±20%), power consumption < 8W

Output: 2-channel relay (5A/250VAC)

- Protection Rating:IP65 (Resistant to water spray and dust)

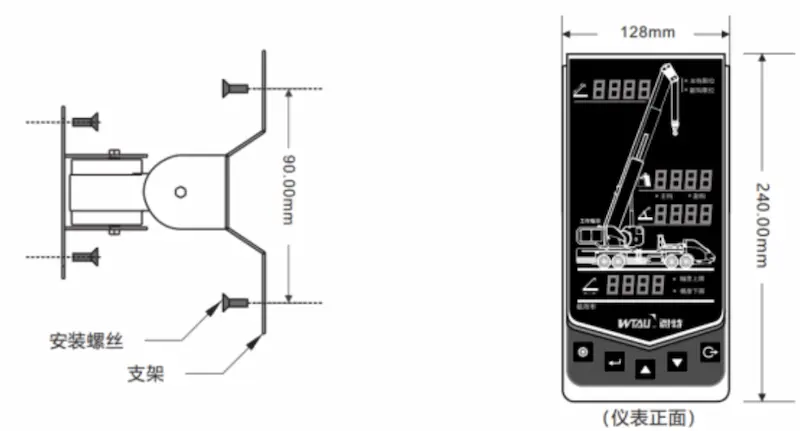

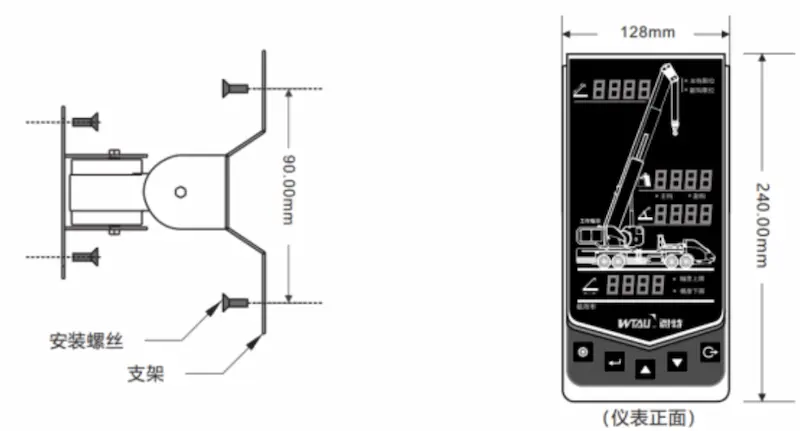

6. Dimensions and Installation

Compact industrial design

- Host sizeLength: 128mm × Width: 240mm × height: 90mm

- Installation method:

→ Bracket fixation: Utilize the four installation holes on the back

→ Embedded installationConsole opening

- Cable interface:

→ Bottom incoming line

Top emergency stop button