1. Product Introduction

The WTL-A200 Moment Limiteris the intelligent safety control core for cranes by WTAU Electronics,validated in the market for 15 years.It features a 240×128 large blue LCD screen that dynamically refreshes key parameters in real time, including main hook load, jib amplitude and load rate. When the load rate is exceeded, the screen immediately turns red and triggers a buzzer alarm of over 60dB, providing national standard-level overload protection for mobile cranes, port gantry cranes and other equipment.

2. Main functions

5-Dimensional Signal Fusion Monitoring & Dual Protection

- Full-Range Signal Acquisition

Synchronously processes2 channels of weight signals(e.g., SHL load sensors) +1 channel of angle signal(jib inclination) +1 channel of height signal(anti-overwinding) +1 channel of length measurement signal(amplitude feedback)

- Three-Level Safety Response

→ Overload Pre-alarm:Flashing yellow screen prompt

→ Overload:Red light lock interface + sound and light alarm

→ Limit Overload:Automatic power cut-off of the winch

- Extended control interface

5-channel relay output for controlling peripheral equipment

RS485/4-20mA supports remote centralized control

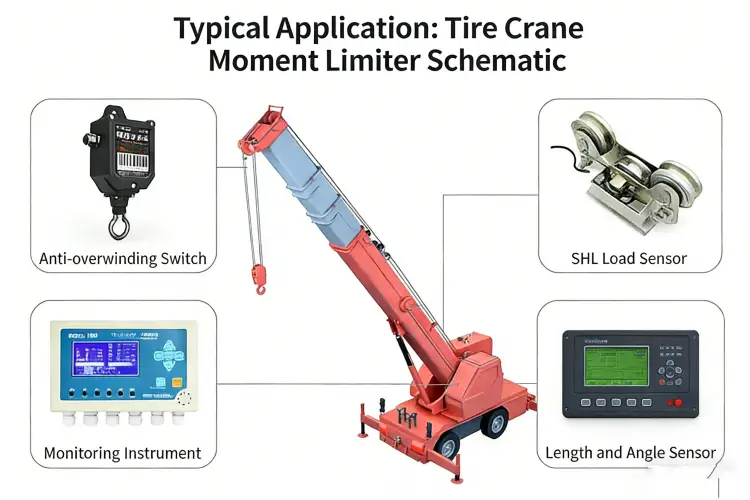

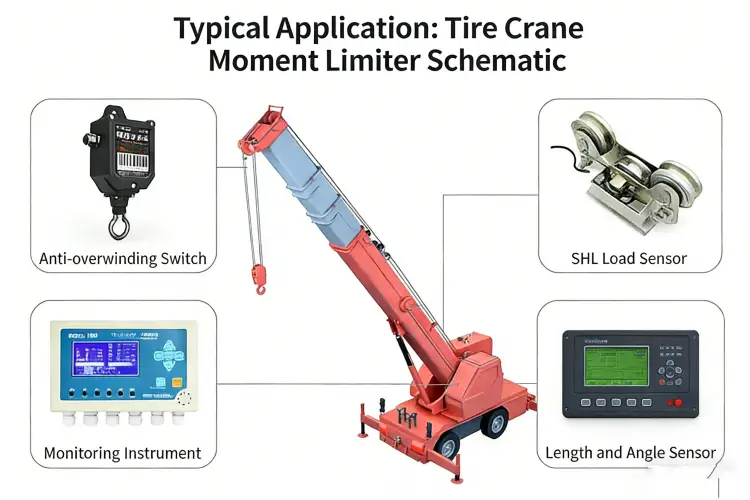

3. Typical application configuration

Moment Limiter for Rubber-tyred Cranes

① Sensing Network Deployment

- Top of the hook: Anti-overwinding switch (black component in the above figure)

- Fixed end of steel wire rope:SHL load sensor (silver module in the above figure)

- Jib hinge point:Integrated length & angle sensor (red device in the above figure)

② Control terminal

- Cab instrument: Off-white host (marked "Monitoring Instrument" in the above figure)

→ Real-time display: "Main Hook 16.5t | Load 01.42t | Load Rate 120.0%!" (screen simulation in the above figure)

4. Core advantages

Industrial-grade Reliability Validated for 15 Years

✅ Expand unbounded

Dual communication interfaces are reserved for direct connection to outdoor LED large screens for displaying working condition data.

✅ Ultra-long Service Life

Fully sealed metal housing + wide-temperature chips (-20℃~60℃) with a service life of up to 10 years.

✅ 3-Minute Relocation & Installation

Users can independently complete reset and debugging.

5. Technical parameters

- Monitoring accuracy:Systematic error ≤±5% (far superior to the national standard ±8%)

- Environmental Resistance:: 95% non-condensing humidity | IP64 dust and water resistance (withstands high-pressure water mist)

- Electrical Characteristics::

→ Power supply: AC220V±10% | Power consumption <35W (continuous operation without frequency reduction)

Control output: 5-channel relays (contact capacity 10A/220VAC)

Alarm volume: >60dB (clearly audible within 15 meters)

- Refresh Speed:Key data updated in real time at 200ms

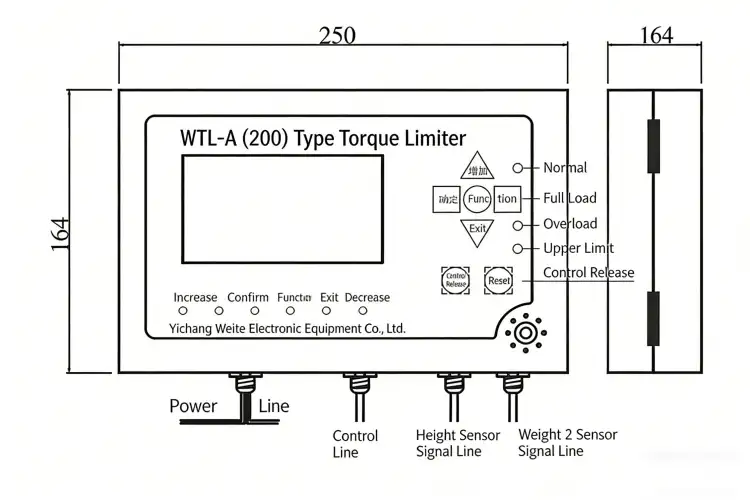

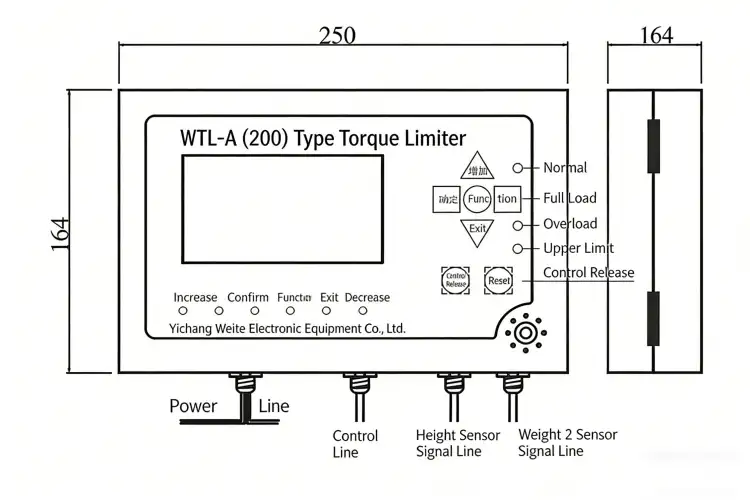

6. Installation specifications

Industrial Cabinet Compatible Design

- Overall dimensions:250mm (L) × 164mm (H) × 70mm (D) (approximately the size of an A4 paper)

- Core features:

→ Physical key area: 5-key layout on the right side (Increase/Confirm/Function/Exit/Decrease)

→ Emergency control key: Independent yellow "Control Release" and "Reset" buttons at the bottom

→ Cable definition(Bottom interface from left to right) :

- Power cord: AC220V input (brown/blue wires)

- Control cable:Relay output (yellow group)

- Height sensing:Anti-overwinding signal (green)

- Weight sensing: Main/auxiliary hook load measurement (gray/white)