Product introduction: "Content Hide 1. Product Introduction 2. Main functions 3.......

WTL-A700 amplitude variable torque limiter

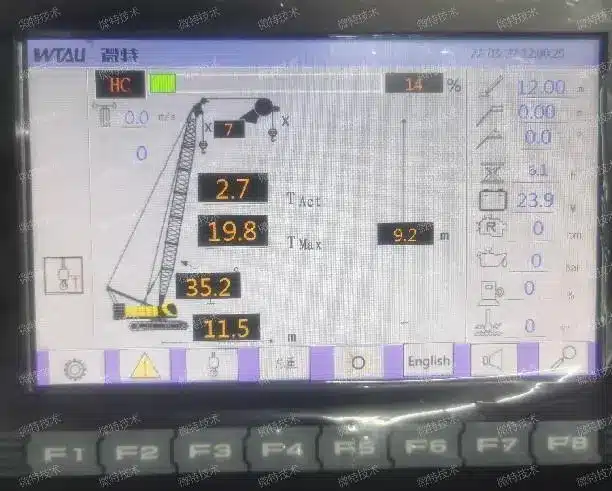

The core device for crane safety protection has passedDynamically monitor the Angle, amplitude and load of the boomCalculate the actual torque value in real time. When approaching the critical state, it automatically triggers an audible and visual alarm and cuts off dangerous actions, effectively preventing overloading, overturning and structural damage. The core adopts high-precision sensors and adaptive algorithms to precisely adapt to complex luffing conditions such as port hoisting and wind power installation.

Triple safety protection closed loop

High-end crane safety essential scenarios

Micro and Special Torque Safety Two-Party Case

Six major technical barriers define industry benchmarks

✅ dynamic adaptive algorithm

The floating crane operation automatically compensates for the wave inclination Angle, and the wind power hoisting matches the blade swing trajectory in real time

✅ millisecond response mechanism

From sensor collection to power cut-off

✅ environmental tolerance

Verification of cold start at -420℃ and full-load operation at 60℃

✅ zero false alarm technology guarantee

Original vibration filtering algorithm

✅ scalable iot architecture

Reserve 5G/ fiber optic interfaces for seamless integration with the smart construction site system

The simple option method is as follows: For large-scale projects, WTL-A700 is recommended, which supports future intelligent upgrades. For medium and small-sized equipment such as medium and small-sized truck cranes and conventional tower cranes , WTL-A200 can be chosen for those who pursue cost performance

Precisely match according to the working conditions and requirements

| Equipment type | Recommended model | Core reason |

|---|---|---|

| A 1,200-ton crane vessel | WTL-A700 | Dynamic wave compensation and multi-action interlocking are required |

| 5MW wind power installation platform | WTL-A700 | Precise tracking of blade swing trajectories |

| Small and medium-sized truck cranes (≤80 tons) | WTL-A200 | Dual-signal input meets the national standard for basic protection |

| Port gantry crane (limited budget) | WTL-A200 | Wall-mounted installation saves space |

The Iron law of Selection

A model of heavy hoisting at sea

A 1,200-ton crane vessel in Haixi, Qingdao

Hengtong Yihang 650-ton full-rotation crane vessel

Previous: Grab beam pin sensor in place

Next Article:WTL-A710 Hydraulic torque limiter »