Product introduction: "Content Hide Core advantages Technical parameters Whole machine ruler...

WTZ-A100N lifting capacity limiterIt is the "intelligent safety scale" installed for equipment such as electric hoists and single-girder cranes. This thing is a solid product accumulated by Weite Electronics over more than ten years of experience, specifically focusing on the lifting capacity of a single steel wire rope. For instance, a steel plant in Wuhan installed it on a bridge crane. The real-time weight jumps clearly on a 0.8-inch large digital tube (the bright red display is even more eye-catching than a mobile phone screen). When it is overweight, it immediately howles - a 60-decibel beeping sound similar to a car horn, along with a red warning light flashing so brightly that it blinds people's eyes, and directly cuts off the power supply to protect the equipment. The most amazing part is that it can be connected to an external LED large screen. Even a forklift driver from 30 meters away can see the bright warning "8.8 tons".

First of all, there is the manufacturing process. The circuit board is wrapped with military-grade three-proof adhesive, which remains sensitive even when frozen into ice lumps at -20 ℃ and does not malfunction even in 60℃ high temperatures. Before leaving the factory, it also has to undergo a 72-hour "sauna room" test (not damaged by 95% humidity). Secondly, it features foolproof operation. All Settings (setting, shifting, adding and subtracting, and confirming) can be completed with just four buttons. An electrician in a warehouse in Zhengzhou reported that two units were installed in half a small time, and there was no need to recalibrate when moving and reinstalling them. Finally, it has strong scalability. The RS485 interface can be connected to the factory's central control system. A certain logistics park in Tangshan relied on this function to monitor the real-time weight of twenty hoists in the duty room.

The key point is just one sentence: the error is less than ±5% (the national standard requires ±8%), which is even more accurate than the electronic scale in the market. Cold resistance and heat resistance are basic skills (as stable as an old dog from -20℃ to 60℃), with an IP54 protection rating for rain and dust resistance. It can be used with either 220V or 24V voltage, and its power consumption is less than 15 watts, which is even more energy-efficient than a light bulb. The alarm volume was over 60 decibels. In a certain workshop in Wuhan, when the alarm went off, people in the adjacent equipment room kept covering their ears.

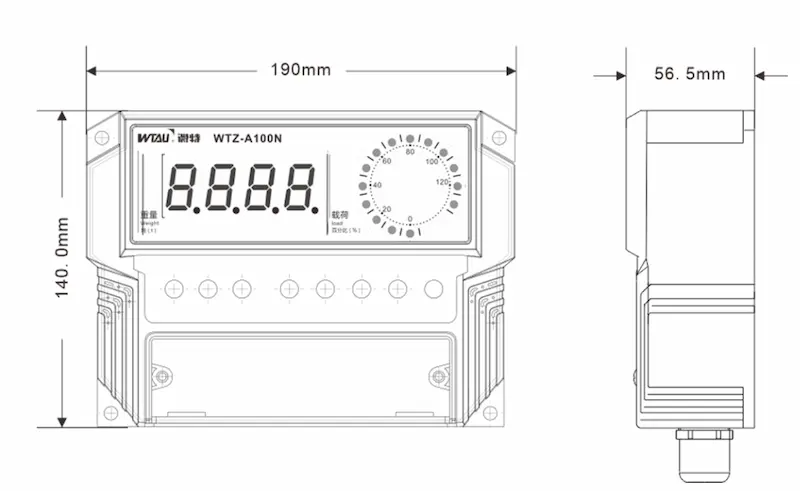

The whole machine measures 190mm in length, 140mm in height and 56.5mm in thickness. It can be wall-mounted with just two screws. The panel design is particularly thoughtful: the "Shift/Settings" key on the left adjusts parameters, the "Add/Subtract" key on the right changes the threshold, and the large digital tube in the middle displays the weight - an experienced worker from a certain steel plant said that with presbyopia, he can clearly see the number "18.8" even from a distance of three meters.

Just like the red crane in the picture, the sensor is directly clamped at the force-bearing point of the steel wire rope, the black hook of the anti-overwinding switch is suspended beside the hook, and the monitoring instrument is installed in the cab and can be reached with a stretch of the hand. Last year, an accident occurred at a certain machinery factory in Tianjin. When the crane was hoisting a 12-ton steel beam, the steel wire rope creaked. It was thanks to this system that the alarm was given in advance, thus avoiding a beam collapse accident. Nowadays, when getting a new machine, everyone remembers to hold down the SET key for 5 seconds to reset it, and when it is overloaded, press the shift key to clear the alarm - maintenance personnel are well aware of these tricks.

Previous: WTZ-A20 lifting weight limiter (electric hoist overload limiter)

Next Article:WTZ-A270 lifting capacity limiter »