1. Product Introduction

WTYZ Series Deepwater Hydraulic Power Station

Designed specifically for water conservancy and hydropower projects150-meter-class underwater hydraulic power sourceIt is compatible with hydraulic automatic grab beams, cleaning machines and grabs. The oil tank, oil pump and valve group are integrated into the pressure-resistant tank body. The 7MPa water pressure protection is achieved through a 27SiMn alloy steel /A304 stainless steel (wall thickness 8-10mm) structure, providing stable power for 5t-600t lifting point equipment.

2. Main functions

Precise power control in deep water environments

- Dual-mode hydraulic output

→ Beam grab controlUnidirectional/bidirectional hydraulic pump output (flow rate ≤14L/min, pressure ≤2.5MPa)

→ Decontamination operationHigh-flow hydraulic drive (16L min, pressure adjustable to 12MPa)

- Dynamic sealing management

→ Oil pipe joint +Aviation plugDouble-seal scheme

- Wide-area environment adaptation

Low-temperature hydraulic oil ranging from -30℃ to 60℃ ensures extremely cold start-up

3. Scope of application

Comprehensive coverage of harsh working conditions

| Application equipment |

Adapt to scenarios |

Key parameters |

| Hydraulic automatic beam grasping |

Hoisting of hydropower station gates (water depth <150m) |

Flow rate ≤14L/min, pressure 2.5MPa |

| Hydraulic cleaning machine/grab bucket |

River garbage clearance |

Flow rate >16L/min, pressure 2.5-12MPa |

| Structural form |

Typical scenarios |

Advantage |

| Tank-shaped/circular pumping station |

Space-constrained installation environment |

Compact integrated design |

| Split-type pumping station |

The demand for power separation of large grab buckets |

Modular quick disassembly and assembly |

4. Core advantages

The four irreplaceable barriers of deepwater engineering

✅ high-pressure-resistant structure

- 8-10mm thick alloy steel/stainless steel cabin (7MPa designed water pressure)

- The inner and outer anti-corrosion coating is stable and reliable

✅ Component configuration

- Rexroth/Parker solenoid valves and joint venture brand gear pumps (1.5-2.2KW motors)

✅ intelligent seal verification

- The first 30-minute deep dive insulation test

✅ reliable operation throughout the full temperature range

- 32 # low-temperature hydraulic oil is supportedIce-breaking start at 30℃

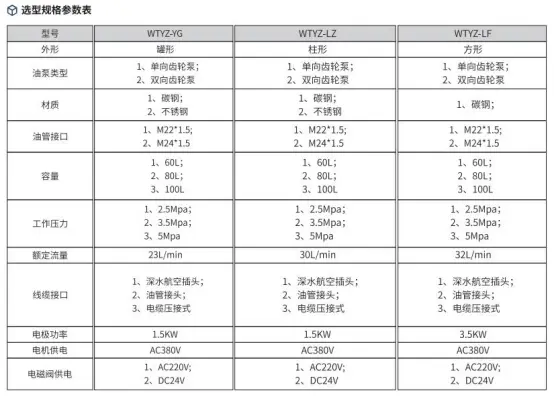

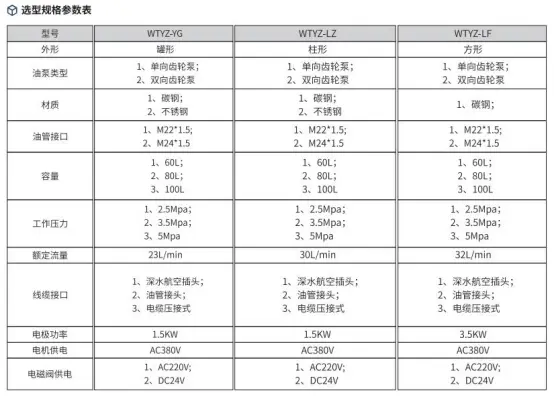

5. Technical parameters

Core performance indicators

- Pressure-resistant shell27SiMn/A304 stainless steelThe wall thickness is 8 to 10mm

- Volume specification60L/80L/100L (Customized up to 300L)

- Hydraulic system:

→ Working pressure: 2.5MPa for the grab beam; 2.5-12MPa for the cleaning machine (adjustable)

Flow range: 20/23/30L/min

- Power unit:

Motor power: 1.5KW/2.2KW (AC380V)

→ Oil pipe interfaceM24×1.5 threaded seal

- Environmental tolerance:

Temperature: -30℃ ~ +60℃

Water depth:≤150m(Design pressure: 7MPa

6. Option Guidance

Step 1: Confirm the type of equipment

▶ Hydraulic grab beamSelection path:

- Pin shaft diameter < 200mm →Flow rate: 10L/min

- Structural forms: can-shaped/circular/square/split type

- Type of hydraulic pumpA One-way (standard configuration) B Two-way (customization required)

▶ Hydraulic cleaning machine/grab bucketSelection path:

- Mandatory choiceFlow rate > 16L/minPressure: 3.5-12MPa

- Structural form: Circular/split type

- Control cableIt is mandatory to use waterproof socket type

Step 2: Selection of the sealing solution

- Tubing pair jointEconomical solution

- Aviation plugPlease indicate the model of the aviation plug

Step 3: Extreme environmental requirements

- Areas with temperatures below -10℃ →Mandatory use of aviation hydraulic oil

- Seawater conditionsSpecify A304 stainless steel material

Customized promptEquipment drawings, working water depth and pressure curve graphs need to be provided

Appendix: Iron Rules for Safe Operation

- Sealing bolts must not be tightened a second timeThe failure risk increases by 300%

- It must be executed before the first useA 30-minute pressure-holding test in 150-meter deep water

- Oil replacement cycleOr 2,000 hours per year(First come, first served)