1. Product Introduction

WT-W650V3 type torque limiterIt is specifically designed forExtreme working condition craneThe designed intelligent security hub. byMicrocomputer host + weight sensor + Angle sensorComposed of three major modules, it has successfully broken the monopoly of foreign technologies in the field of offshore platforms. Its IP65 protective housing and wide temperature range design (-20℃ to +70℃) have been verified for reliability on many offshore drilling platforms around the world.

2. Main functions

Marine-grade triple safety protection

- Dynamic load tracking→ Bh force sensor monitors loads ranging from 0 to 1000 tons in real time (error ≤±5%F.S) → 8-inch LCD screen dynamically displays lifting weight/amplitude/moment rate

- Multi-action interlock controlThe 6-channel output precisely cuts off the overloaded hoist. When the wind speed exceeds the limit, the hoisting action freezes

- Adapt to all kinds of harsh Marine environmentsThe commonly supplied products for offshore platform cranes are suitable for all kinds of harsh environments

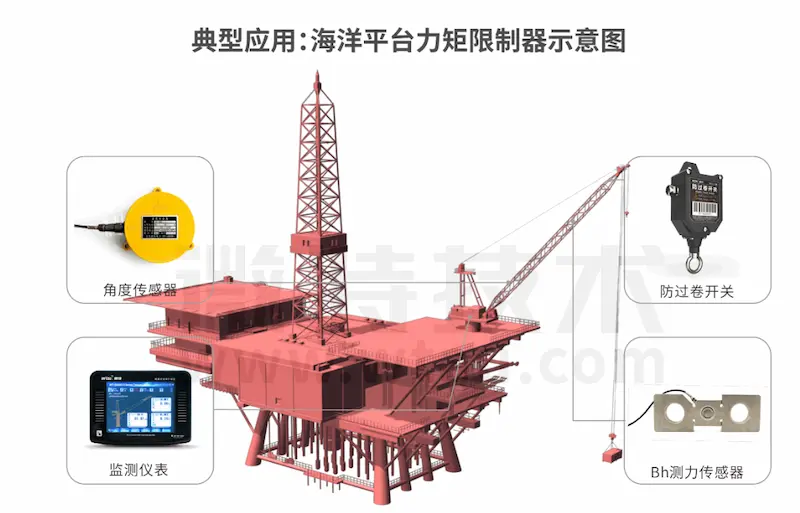

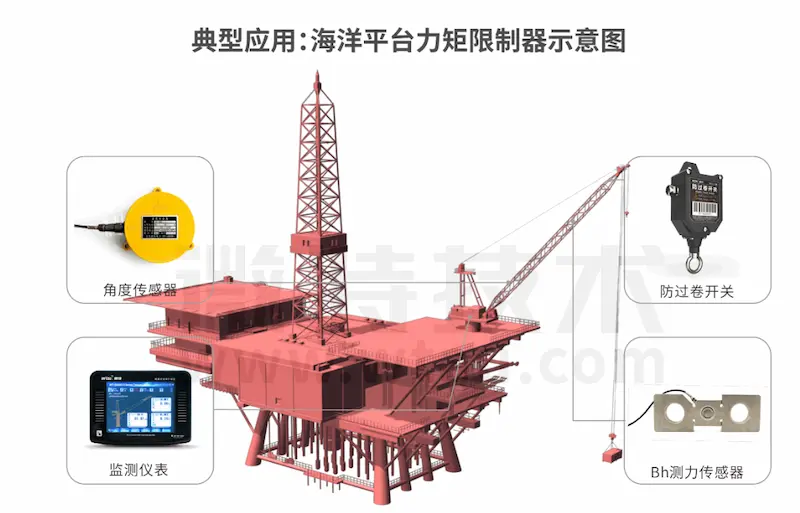

3. Typical applications

Four-dimensional sensor network for offshore platforms

① Environmental Sentinel

- Angle sensor(Upper left yellow disk) : Monitor the boom elevation Angle from -5° to 85°

- Wind speed sensor(Not illustrated but integrated) : Strong wind warning at 60m/s

② Mechanical error prevention

- Anti-overwinding switch(Upper right black hook) : Ultimate mechanical limit of the steel wire rope

③ Intelligent Center

- Monitoring instrument(Lower left display screen) : Controls 6-channel relay output

④ Load core

- Bh force sensor(Silver block at the bottom right) : Hydraulic compensation for anti-wave shaking

4. Core advantages

Marine-level strength verified by a decade of zero accidents

✅ 24200T·m top-level qualification

The type test qualification reaches 24,200 T·m, and the control output can be expanded to a maximum of 24 channels

✅ stable and reliable

The products are subject to strict multi-layer instrument testing and multi-layer quality control personnel inspection before leaving the factory.

✅ forward-looking design

Dynamic simulation displays the working status of the equipment, which is real and intuitive. It can be externally connected to PLC, intelligent instruments, boards, modules, frequency converters and other industrial automation equipment, and is convenient for expansion. It supports data backup and multi-level password protection functions, black box fault record function, SD card data export, etc.

5. Technical parameters

- Performance of the main control machine→ Screen: 8-inch industrial LCD→ Accuracy: ≤±5% (F.S) → Input Signals: ≤6 channels (weight/Angle/wind speed/height)

- Environmental toleranceTemperature: -20℃~+70℃Humidity: 95% no condensation → Alarm volume: > 60dB (clearly audible in storm conditions)

- Electrical characteristics→ Power Supply: AC220V or DC24V→ Power consumption: < 30W

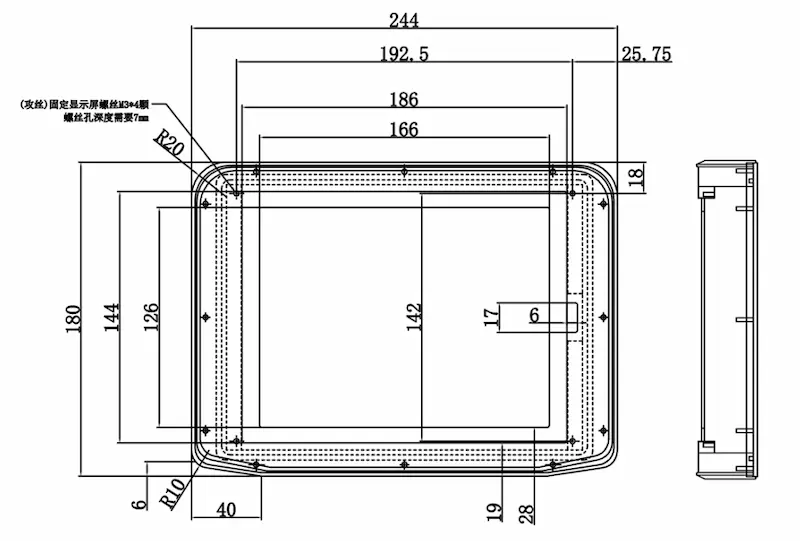

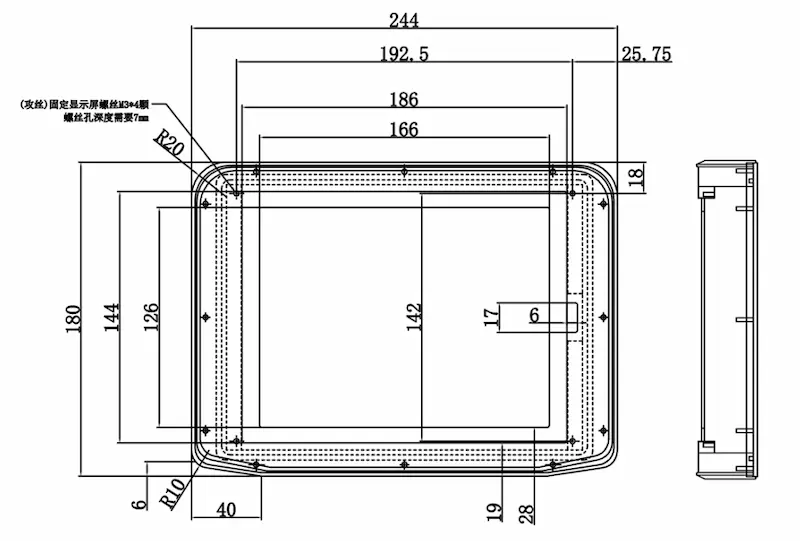

6. Installation specifications

Compact Marine engineering design

- Host size"Long"244mm× Width180mm

- Core structural characteristics:→ Installation hole4×M3 screws (hole depth 7mm, hole pitch 186×166mm) →Heat dissipation grille: Bottom R20 arc flow diversion design (anti-salt spray accumulation) →Screen display area192.5×142mm visible area (anti-glare coating)

- Anti-vibration design16mm shock-absorbing frame/Marine rubber sealing ring

7. Engineering cases