1. Product Introduction

WTL-A170 Torque limiterIt is the intelligent safety control core specially designed by Weite for industrial cranes. The integrated slide rail type slot structure can be quickly embedded into the standard guide rail of the electrical cabinet, greatly simplifying the installation process. It is equipped with an internal black box data storage module, which can fully record 10 years of operation data through a USB interface, providing precise basis for accident traceability and maintenance optimization.

2. Main functions

Multi-signal fusion monitoring and active protection

- Full-Range Signal Acquisition

Synchronously processes2 channels of weight signals(Such as Bh force sensor) +Two Angle signals(Such as boom inclination Angle

Independent monitoringThe height of the 2-way hook is designed to prevent overrolling(Prevent the steel wire rope from being overwound

- Triple security response

→ 90% Load sound and Light Warning → 100% cut off dangerous action → 105% Emergency braking

- Data traceability system

The black box continuously records over 100,000 operation data. The CSV analysis report can be directly exported via USB

3. Typical application configuration

Safety protection plan for portal cranes

① Key sensor layout

- Root of the boomYellow Angle sensor (for monitoring amplitude variation Angle)

- Fixed end of steel wire rope:Silver Bh force sensor (real-time load acquisition)

- Side of the drumBlack anti-overwinding switch (height limit redundancy protection)

② Control center

- Cab/Electrical control cabinetGrey main control instrument (128×64 LCD screen dynamically displays torque percentage)

4. Core advantages

Ten years of verified industrial-grade reliability

✅ fast installation

The slide rail clip "locks with one push", and the deployment can be completed in 3 minutes (saving 801T and 3T of working hours compared to traditional screw fixation)

✅ safety protection

IP64 dust and water resistance + three-proof varnish circuit board (resistant to extreme temperature variation from -20℃ to 60℃)

✅ intelligent operation and maintenance

Jitter delay algorithm eliminates false alarms; power-off memory retains key data

✅ flexible expansion

Reserve an RS485/4-20mA interface to support external connection to large screens or PLC centralized control

5. Technical parameters

- Monitoring accuracy:Systematic error ≤±5% (national standard requirement ≤±8%)

- Environmental Resistance:Temperature: -20℃ to 60℃; Humidity: 951 ° T - 3T. No condensation

- Electrical Characteristics::

Power supply: AC220V±10% (Power consumption < 35W)

Control output: ≤8 relay channels (contact capacity 5A/250V)

- Data capability:

Storage record: > 10 years (cyclic overwrite)

USB interface: Standard Type-A (FAT32 format compatible)

- Alarm responseThe buzzer volume is greater than 60dB (audible from 15 meters).

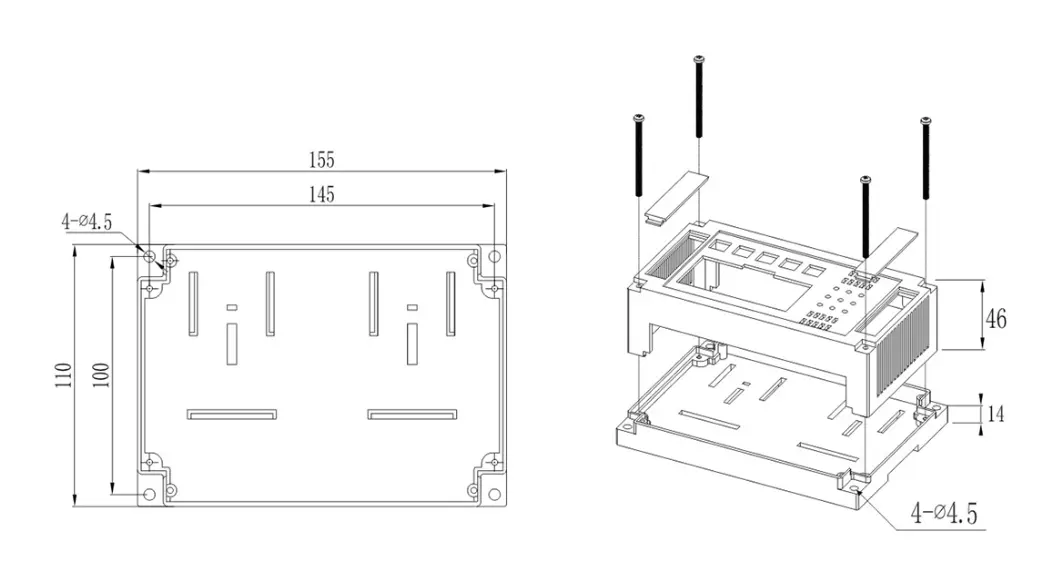

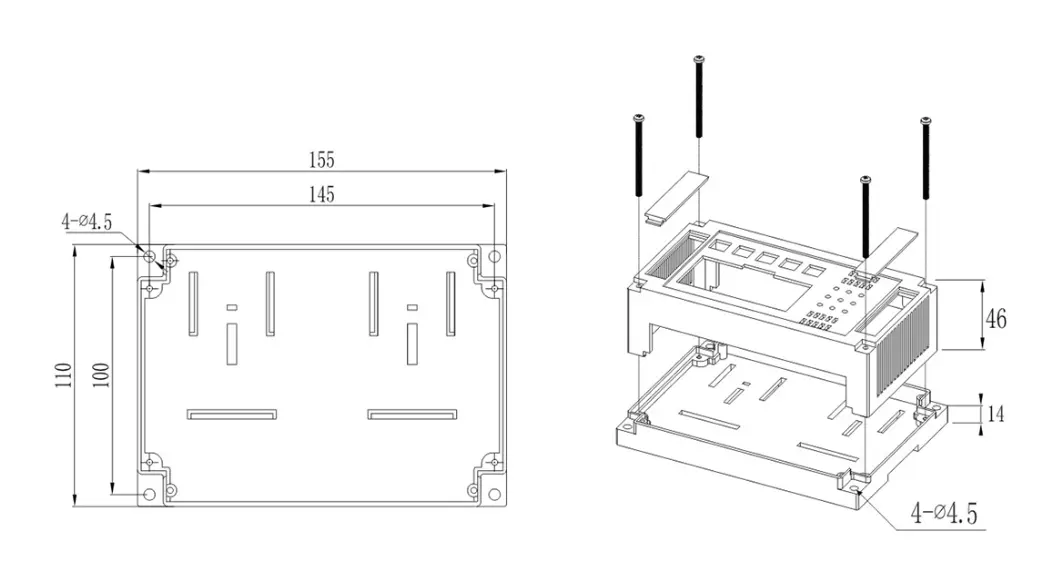

6. Dimensions and Installation

A model of compact industrial design

- Host sizeLength: 155mm × Width: 110mm × height: 60mm

- Core structural characteristics:

→ 4×φ4.5mm installation holesCompatible with M4 screw wall-mounted fixation

→ Slide rail slotTop 46mm protruding snapper (compatible with 35mm standard guide rail)

→ The bottom is hollowed out for heat dissipation14mm wide grid design (reduces 301T to 3T temperature rise)

- Cable management:

Rear-mounted cable inlet trough (supporting Φ8 to 12mm wire diameters)

Aviation plug optional installation position (Please note in advance)