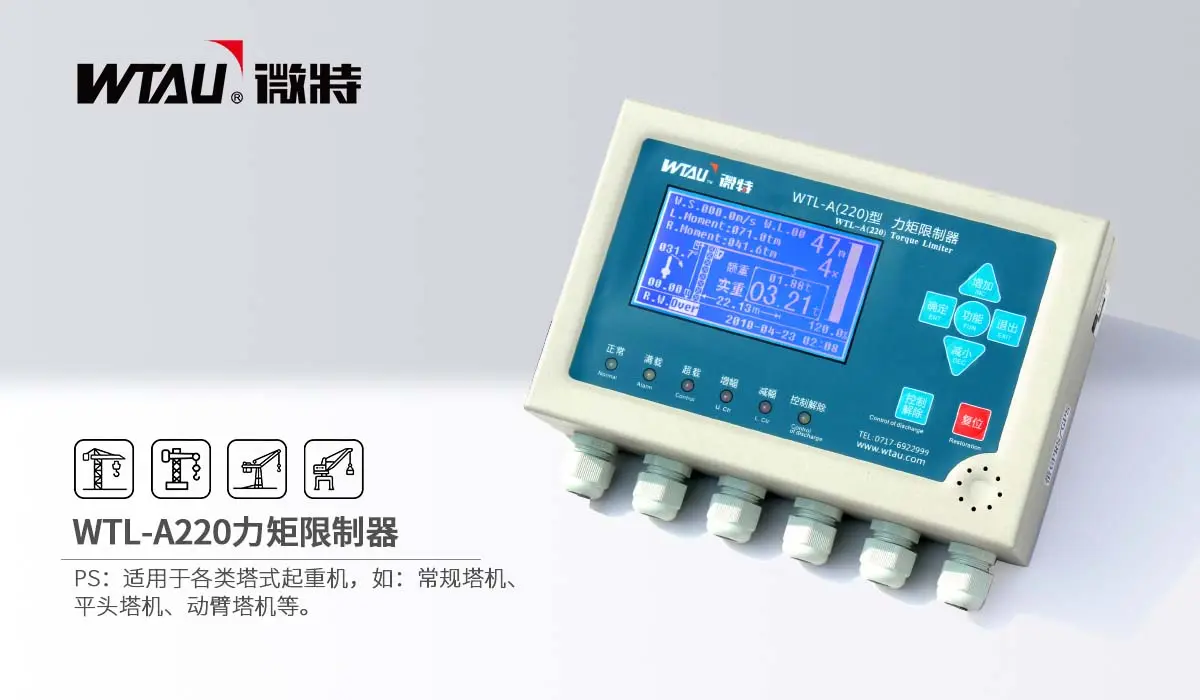

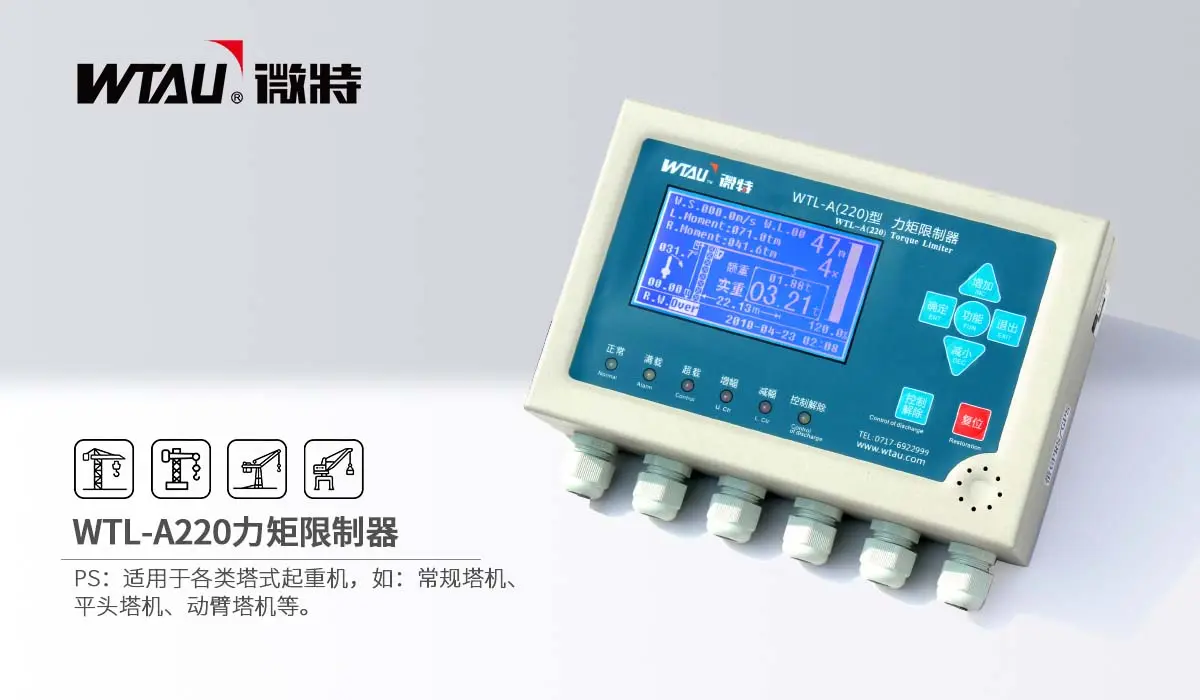

1. Product Introduction

WTL-A220 torque limiteris aIntelligent safety hub for tower cranes(Won the Major Scientific and Technological Achievement Award of Hubei Province) Designed specifically for tower cranes, it builds a millisecond-level safety protection closed loop by real-time monitoring of six parameters including lifting weight, amplitude, height, orientation and wind speed. Its split structure design supports 3-limit / 6-limit custom configuration and integration simultaneouslyBlack box recordwith4G remote transmissionDual-core function.

2. Main functions

Six-dimensional perception and triple protection system

- All-domain signal fusion

→ Lifting load(±1% accuracyAmplitude(±0.1m)|Height(±2cm)

→ Azimuth(0-360°)|Wind speed(0-60m/s)|GPS positioning(±5m)

- Active security defenseEarly warning + interception + traceability

- Remote cluster control and management

"4G transparent transmission of working conditions to the monitoring platform: Remote locking/unlocking.

3. Typical application configuration

Standard Deployment Plan for Flat-arm Tower Cranes

① Sensor network layout

- Top of the towerBlack wind speed sensor (resistant to typhoons of up to level 16

- BoomYellow travel limiter (to prevent the vehicle from overstepping

- Hook assemblyAnti-overwinding switch (Ultimate protection for steel wire rope)

- Fixed end of steel wire rope:Silver weight sensor (strain bridge type)

- Rotary mechanismGrey azimuth sensor (absolute value encoder)

② Control terminal

- CabBeige main control machine (240×128 Blu-ray LCD screen)

4. Core advantages

The three major technical barriers verified over fifteen years

✅ reliability

-20℃ cold start without delay; 95% humidity anti-condensation circuit; IP64 protection against heavy rain wash

✅ simplified operation system

Users can independently complete the relocation and installation

✅ judicial retroactive capacity

The aerospace-grade black box supports one-second scene restoration of accidents

5. Technical parameters

- Performance of the main control machine

Screen: 240×128 industrial LCD (visible in strong light)

Error: ≤±5% FS (National standard requirement: ≤±8%)

Power consumption: < 35W (AC220V±10%)

- Environmental Resistance:

Temperature: -20℃~+60℃

"Protection:IP64(Dust-proof/splash-proof

- Expansion capability

Control output: ≤8 channels of relays (contacts 10A/220V)

Communication interface: RS485/4-20mA (customization supported)

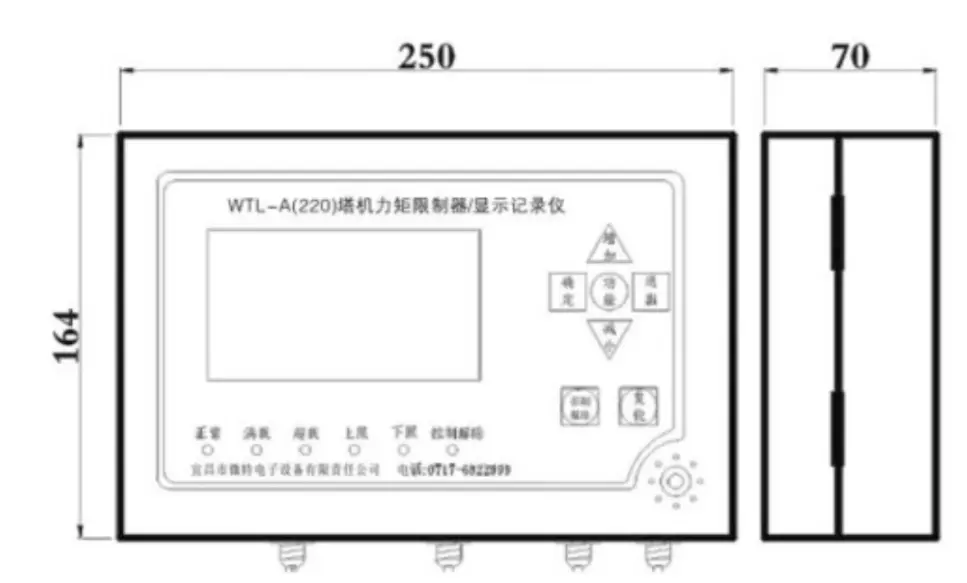

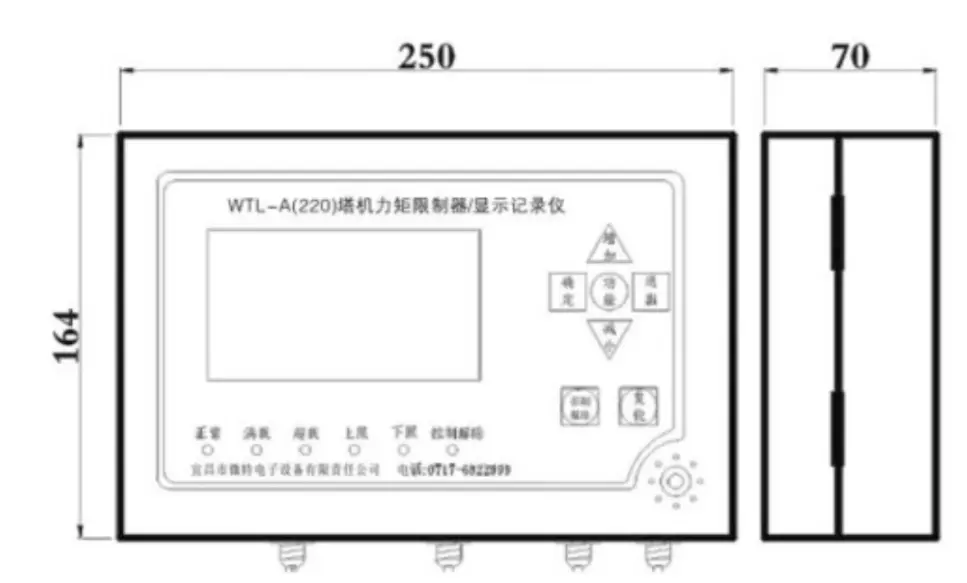

6. Installation specifications

Industrial compact design

- Chassis Dimensions:(L)250mm× (W)164mm× (D)70mm

- Key structural features:

→ Key area: Right cross key (↑↓←→ Confirm) + independent reset key

→ Status light6-color LED indication (overload/full load/height limit, etc.)

→ Bottom interface:

· Power input: AC220V three-core socket

· Signal input: 6 aviation jacks (corresponding to sensors)

· Control output: 8-channel terminal block

- Installation method:

Wall-mounted: 4×φ5mm holes on the back (hole spacing 220×150mm)

Bracket: Standard L-shaped adapter plate (anti-vibration design)