Product introduction: "Content Hide 1. Product Introduction 2. Main functions ...

WTL-A700 torque limiterIt is Weite ElectronicsSuper-heavy lifting equipmentThe intelligent security hub developed (verified in the market for ten years). It adopts an industrial-grade full lamination touch screen and achieves millisecond-level response through a modular CPU motherboard. Its core value lies in24,200 T·m class torque protection qualificationProvide multi-hook coordinated safety protection for equipment such as floating cranes and gantry cranes.

Multi-hook coordination and intelligent defense system

→ Boom amplitudeLaser ranging is resistant to vibration interference

→ Rotation AngleAbsolute value encoding to prevent step loss

Directly connect to PLC/ frequency converter to achieve hoisting automation

Multi-hook coordination scheme for 10,000-ton floating cranes

① Core sensing layout

② Control terminal

The three major barriers to heavy-load engineering verification

✅ super applicability

The type test qualification reaches 24,200 T·m, and the control output can be expanded to up to 24 channels, supporting various special functional requirements for expansion and customization. It meets the multi-hook moment safety protection and additional management functions for various large floating cranes, crawler cranes, gantry cranes and other lifting equipment.

✅ Stability and reliability

The commonly supplied products for offshore platform cranes are suitable for all kinds of harsh environments. The products are subject to strict multi-layer instrument testing and multi-layer quality control personnel inspection before leaving the factory. Products in regular inventory owned by large domestic and foreign users.

✅ forward-looking design

Dynamic simulation displays the working status of the equipment, which is real and intuitive. It can be externally connected to PLC, intelligent instruments, boards, modules, frequency converters and other industrial automation equipment, and is convenient for expansion. It supports data backup and multi-level password protection functions, black box fault record function, SD card data export, etc.

Output mode: Switch quantity /RS485/4-20mA

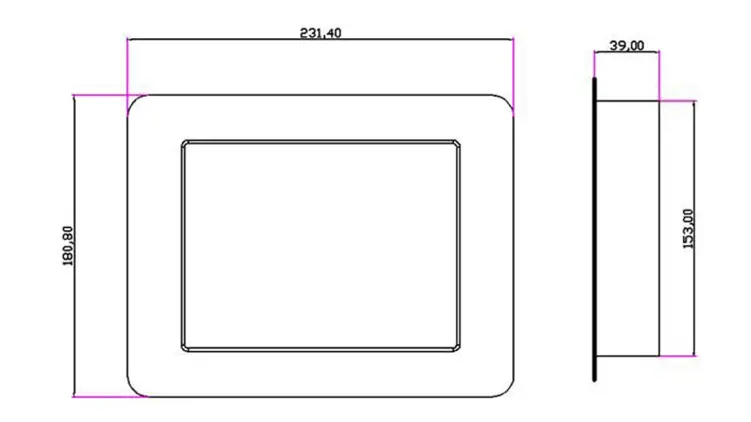

Compact design for heavy industry

→ Emergency stop buttonThe red mushroom-shaped head on the right (protruding by 25mm)

→ Heat dissipation systemBottom honeycomb heat dissipation holes (8mm spacing)

→ Cable management:

Previous: Anti-job-changing AI early warning system for wire rope reel

Next Article:Non-standard customized torque limiter »